Understanding which interior linings enhance insulation in cooler bags is essential for manufacturers, retailers, and buyers seeking optimal cold retention. This list compiles expert insights and proven materials to help guide professional decisions in product development and bulk purchases.

6 Interior Linings That Boost Insulation in Cooler Bags

These six interior linings significantly improve cooler bag insulation by minimizing heat transfer through conduction, convection, and radiation.

Each material offers unique benefits. Read on to understand which is best suited for your product's performance goals.

Closed-Cell Foam1 Insulation

Closed-cell foam is a premium insulation material found in top-tier cooler bags.

Why Closed-Cell Foam Excels

Closed-cell foam traps cold air inside and blocks moisture penetration. It’s one of the densest foams used in insulation, delivering maximum cold retention. YETI and Engel use this material in their high-end cooler bags for long-term cold storage, making it a benchmark for thermal performance.

Key Characteristics and Uses

| Feature | Benefit | Use Case |

|---|---|---|

| Dense structure | Limits heat transfer | Premium cooler bags |

| Moisture-resistant | Prevents internal sweating | Outdoor and marine use |

| Excellent insulation | Long-lasting cooling | Camping, travel |

When combined with outer hard shells or thick fabrics, closed-cell foam increases durability and structure.

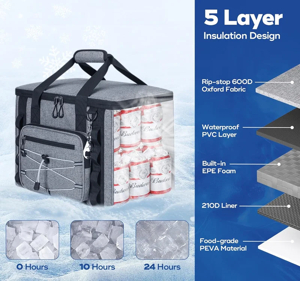

Expanded Polyethylene (EPE) Foam

EPE foam offers an ideal balance between insulation, weight, and cost.

Lightweight Versatility of EPE

EPE is popular because it's customizable and lightweight. Manufacturers can select thicknesses ranging from 1mm to 25mm to control insulation levels. It’s common in delivery bags, mid-range cooler totes, and supermarket promotional items.

Applications and Features

| Feature | Benefit | Use Case |

|---|---|---|

| Adjustable thickness | Tailored cooling duration | Delivery bags |

| Lightweight | Easier portability | Personal coolers |

| Water-resistant | Keeps bag interior dry | Food transportation |

EPE foam layers often work best when paired with reflective foil to combat radiant heat.

Polyurethane Foam2

Polyurethane foam is an industry standard for deep cooling needs.

When to Use Polyurethane Foam

Polyurethane foam excels in applications requiring prolonged cold storage. It has a tighter cell structure than EPE, which blocks more air and slows down heat exchange. It's common in medical supply bags and high-end lunch carriers.

Comparison and Application

| Feature | Benefit | Use Case |

|---|---|---|

| Tighter cells | High insulation capacity | Long-haul transport |

| Durable | Maintains shape and function | Reusable coolers |

| Temperature control | Effective in extremes | Pharmaceutical logistics |

Because it's denser and heavier, polyurethane foam is usually reserved for professional or industrial uses.

Reflective Foil Linings3 (Aluminum Foil or Mylar)

Reflective linings are used to bounce radiant heat away from contents.

How Reflective Foils Work

Aluminum foil or metalized polyester (Mylar) linings are thin but powerful. By reflecting thermal radiation, they prevent external heat from warming up the bag’s contents. Often used with foam for added insulation, these linings are essential for hot climates.

Benefits and Design Use

| Feature | Benefit | Use Case |

|---|---|---|

| Reflective surface | Reduces radiant heat | High-temperature settings |

| Lightweight | Adds minimal bulk | Everyday lunch bags |

| Flexible pairing | Works with foam | Combo-layer insulation |

Mylar linings offer a shiny, professional look while improving performance in heat-heavy environments.

PEVA (Polyethylene Vinyl Acetate) Linings

PEVA linings are leak-proof, food-safe, and easy to maintain.

PEVA’s Role in Cooler Bags

PEVA is widely used as the innermost layer of cooler bags. It resists leaks and makes bags easy to clean. While not a primary insulation material, it complements foam layers by acting as a heat barrier and moisture control layer.

Breakdown of Benefits

| Feature | Benefit | Use Case |

|---|---|---|

| Food-grade | Safe for direct food contact | Family cooler bags |

| Waterproof | Prevents leak damage | Beverage carriers |

| Easy to wipe | Quick cleaning | School lunch bags |

Its flexibility and safety make it a go-to choice for personal-use cooler products.

Polyester Wadding or Sponge

Polyester wadding and sponges provide breathable, lightweight insulation.

Adding Air-Trapping Layers

These soft materials work by trapping air within their fibers, reducing heat flow. They are ideal for lighter bags or for combining with other insulating materials. Wadding is cost-effective and can enhance user comfort by making bags more pliable.

Material Profile

| Feature | Benefit | Use Case |

|---|---|---|

| Soft structure | Adds cushion and air trap | Promotional bags |

| Breathable | Enhances comfort | Short-use cooler bags |

| Cheap and available | Budget-friendly insulation | Bulk production |

Often layered with foil or foam, polyester wadding supports multi-layer designs.

Conclusion

Each cooler bag lining material has unique strengths. Closed-cell foam and polyurethane offer top-tier insulation, while EPE and PEVA strike a balance between performance and weight. Reflective foil and polyester wadding serve best in layered insulation systems. I’ve found that combining PEVA with EPE foam and a foil layer works best for most mid-range products. Choose based on your product's cooling duration, target market, and weight preferences.

What materials have worked best in your designs? Share your experience or ask questions in the comments.

-

Explore this link to understand how Closed-Cell Foam can enhance cold retention and moisture resistance in cooler bags, making it a top choice for manufacturers. ↩

-

Learn about the superior insulation properties of Polyurethane Foam and its applications in professional cooler bags, ideal for long-term cold storage. ↩

-

Discover the science behind Reflective Foil Linings and how they can effectively reduce heat transfer, ensuring your cooler bags perform better in hot conditions. ↩