PP woven bag pricing is shaped by material, design, and production factors. This guide outlines five key cost influencers that buyers must understand to make informed sourcing decisions and avoid overspending.

PP woven bag prices are mainly driven by raw material rates, customization levels, fabric weight[^1], functional features, and manufacturing overheads. Understanding these factors helps buyers optimize budget and performance.

Avoid hidden costs and maximize value by learning what really drives pricing below.

Raw Materials (Polypropylene Cost)

Dive-Deeper paragraph: Polypropylene (PP)[^2] is the core material for woven bags, and its price is directly linked to global oil markets. Since PP is derived from crude oil, fluctuations in oil prices ripple down to the cost of PP granules. When crude prices spike due to geopolitical events or supply chain disruptions, so do the raw material costs. This makes up a significant portion—often 60% or more—of the total bag price. Bulk orders placed when oil prices are high may lock buyers into elevated rates unless price hedging is used.

Crude Oil to Bag Price Correlation

| Crude Oil Price (USD/barrel) | Avg. PP Resin Price (USD/ton) | Bag Price Impact (%) |

|---|---|---|

| $70 | $1100 | Base price |

| $90 | $1300 | +10–15% |

| $110 | $1550 | +20–25% |

Bag Design and Customization

Dive-Deeper paragraph: A standard PP woven bag with no printing or lamination costs less to produce. Customization adds extra steps: printing plates, custom dies, lamination layers, or unique cuts. Logos and multicolor branding increase ink consumption and printing time. Non-standard sizes or specialty closures often require tool changes, which raise the unit cost—especially for small to medium orders. Buyers should prioritize which features truly add value and consider volume-based discounts for custom runs.

Customization Cost Examples

| Custom Feature | Added Cost Per Bag | Notes |

|---|---|---|

| 1-color Logo Print | +$0.01–$0.03 | Plate cost adds upfront fee |

| Full-Surface BOPP | +$0.05–$0.08 | Requires separate lamination |

| Die-Cut Handle | +$0.02–$0.04 | Increases material waste |

Bag Strength and Material Thickness

Dive-Deeper paragraph: Thicker polypropylene fabric (measured in GSM—grams per square meter) provides better strength and resistance to tearing or puncture. Bags for cement, grains, or construction use typically require higher GSM and tight weave density. Thicker materials also mean longer extrusion times and more raw material use per unit. Reinforced stitching or extra folds add further durability but also increase time per bag in the production cycle.

Thickness vs. Performance vs. Cost

| Bag Use Case | Recommended GSM | Cost Impact |

|---|---|---|

| Light Retail (5–10 kg) | 60–80 GSM | Low |

| Grain Storage (25–50 kg) | 90–110 GSM | Medium |

| Cement/Fertilizer | 110–140 GSM | High |

Additional Features and Treatments

Dive-Deeper paragraph: Optional features enhance bag performance but raise costs. UV protection[^3] allows bags to withstand sunlight during outdoor storage. Anti-slip coating helps stacking stability. Kraft linings improve structure and moisture resistance. Laminations (BOPP or PE) boost aesthetics and barrier properties. Each feature requires extra material or machine time, which adds to per-unit costs. Buyers must weigh functional benefits versus price impact, especially when buying in large quantities.

Feature Price Table

| Feature | Function | Avg. Cost Increase |

|---|---|---|

| UV Treatment | Prevents sun damage | +$0.01–$0.03 |

| Anti-Slip Coating | Improves stacking safety | +$0.01–$0.02 |

| Kraft Paper Lining | Enhances strength/moisture barrier | +$0.03–$0.05 |

| BOPP Lamination | Improves print quality/durability | +$0.04–$0.08 |

Energy and Labor Costs in Manufacturing

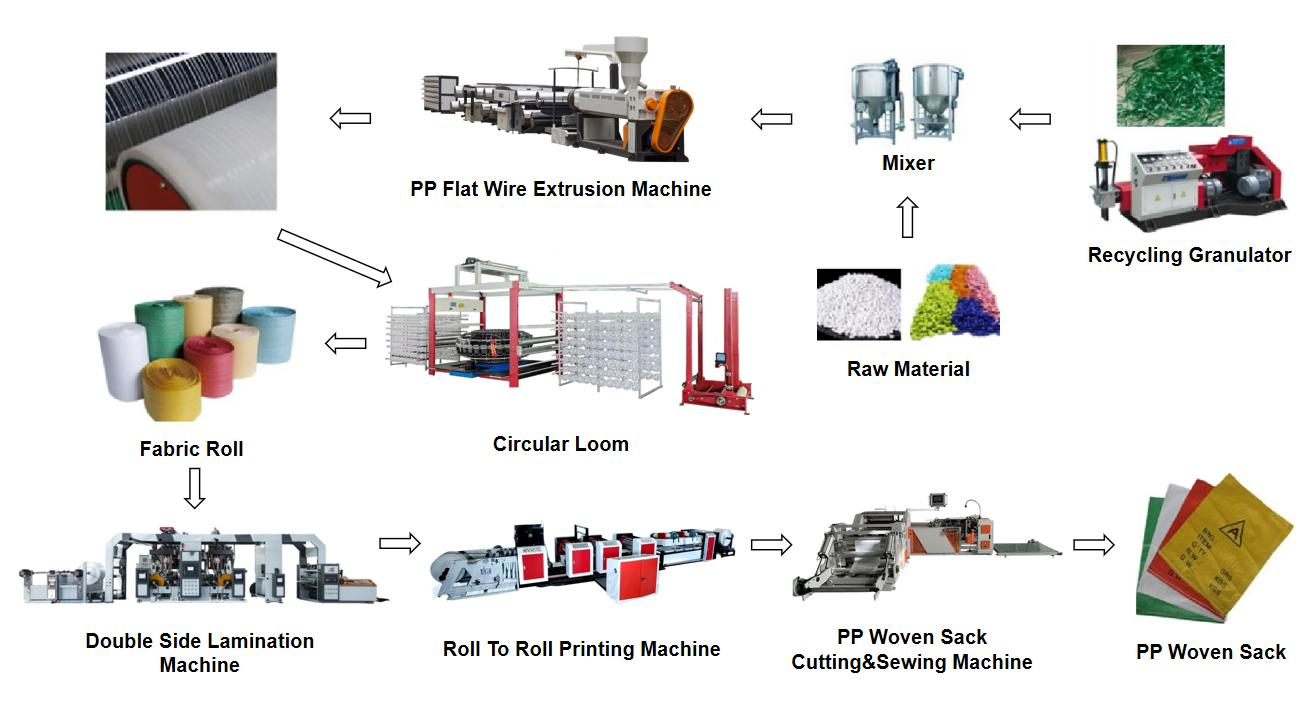

Dive-Deeper paragraph: PP woven bag manufacturing is energy-intensive. Extrusion, lamination, printing, and stitching rely on electricity and machine time. In regions with high electricity tariffs, overall cost rises sharply. Labor is another critical factor—skilled operators ensure quality but add to payroll. Moreover, freight charges, duties, and profit margins contribute to final pricing. Countries with lower production overheads like China or Vietnam typically offer more competitive rates than those with higher labor costs.

Cost Variables by Region

| Region | Labor Cost Impact | Energy Cost Impact | Overall Price Range |

|---|---|---|---|

| Southeast Asia | Low | Low–Medium | Competitive |

| Europe | High | High | Premium |

| Middle East | Medium | Low | Moderate |

Conclusion

PP woven bag prices are not just about quantity—they depend on raw materials, design complexity, structural strength, value-added features[^4], and production economics. At JiaRong Packing, we help buyers find the best balance between cost and performance. For instance, switching from full-surface lamination to targeted branding helped one of our U.S. clients cut packaging costs by 18% without affecting brand visibility.

Which cost factor affects your project most? Drop your situation in the comments for advice.

---

[^1]: Discover how fabric weight influences durability and cost, essential for making the right choice.

[^2]: Learn about the core material that drives the pricing of woven bags and its market dynamics.

[^3]: Discover how UV protection enhances bag performance, especially for outdoor storage.

[^4]: Explore how additional features can enhance product performance but also increase costs.