Cooler bag insulation performance depends on how well it prevents heat transfer through conduction, convection, and radiation. This guide explains the main factors that influence how long your bag can keep items cold.

Factors That Impact Cooler Bag Insulation Performance

The quality and thickness of insulation, reflective materials, sealing design, and usage habits directly determine how long a cooler bag can maintain low temperatures.

Understanding these factors helps you choose a better cooler bag and use it effectively.

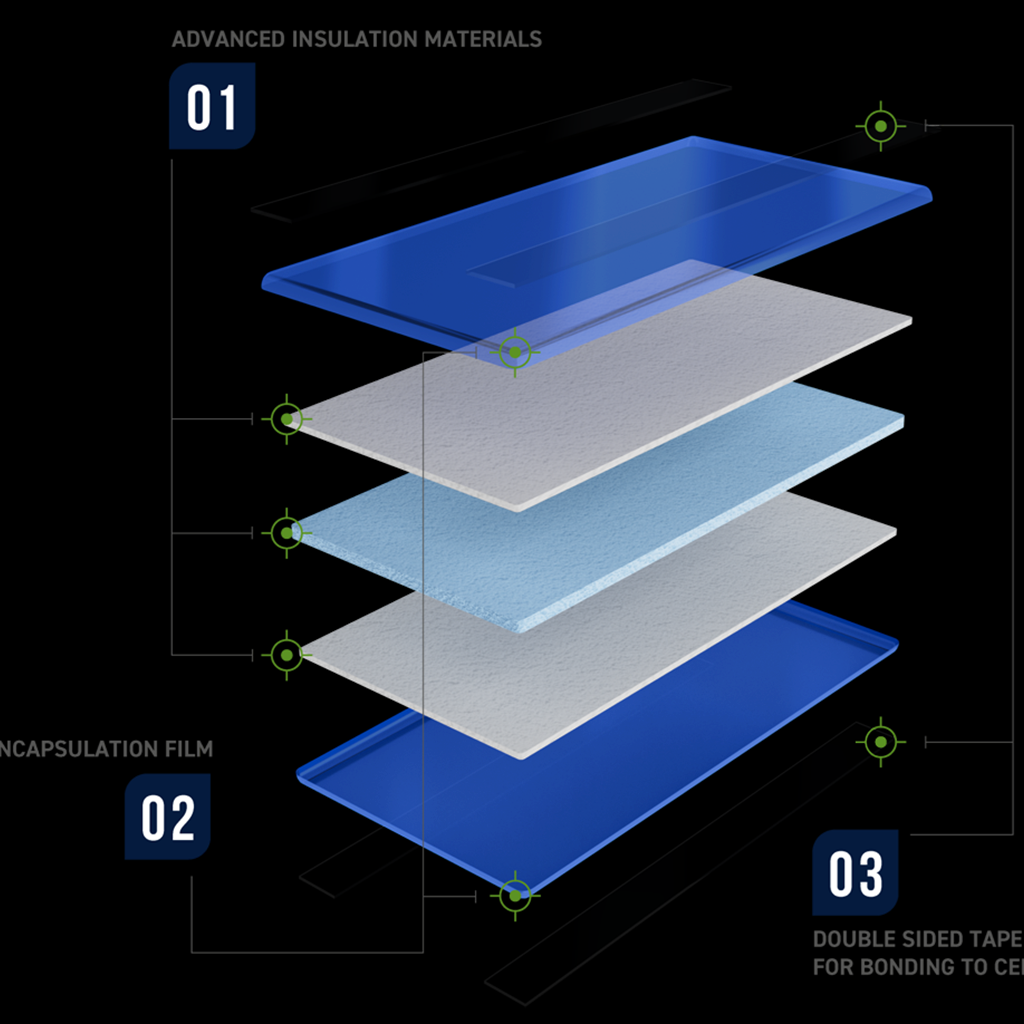

Insulation Material and Thickness1

The foam used inside a cooler bag is the main defense against heat entering. Common high-performance options include polyurethane foam2 and EVA foam. The thickness of the foam directly affects how long the contents stay cold.

How Foam Works

Foam slows heat transfer through conduction by trapping air in small pockets. High-density foam provides a tighter barrier, reducing heat flow. EVA foam1 is lightweight and flexible, while polyurethane foam offers higher insulation at the cost of weight.

| Foam Type | Density | Insulation Level | Weight Impact | Typical Cooling Duration |

|---|---|---|---|---|

| Polyurethane foam3 | High | Excellent | Heavy | 6–8 hours |

| EVA foam4 | Medium | Good | Light | 4–6 hours |

| Basic PE foam | Low | Fair | Very light | 2–4 hours |

Thicker foam usually means better cold retention but adds bulk. The right balance depends on whether portability or maximum cooling is more important for your use.

Reflective Materials

Reflective layers reduce radiant heat from sunlight and warm surroundings. Aluminum foil and metallized films are common choices.

Why Reflection Helps

Radiant heat can bypass foam insulation if not blocked. A reflective layer sends much of this heat away before it penetrates the bag. This is especially important in direct sunlight or hot environments.

| Material | Reflective Efficiency | Added Weight | Durability |

|---|---|---|---|

| Aluminum foil layer | Very High | Low | Moderate |

| Metallized film | High | Very Low | High |

Bags with both foam and reflective layers perform better than foam-only designs when exposed to high radiant heat.

Thermal Liners

Thermal liners form the inner surface of the cooler bag, helping maintain temperature and resist moisture buildup.

Liner Types and Benefits

Smooth thermal fabrics, such as food-grade PEVA or Thinsulate, create a clean, insulated interior. Thinsulate is known for excellent temperature retention in thin layers. A good liner also prevents leaks and makes cleaning easier.

| Liner Type | Thermal Performance | Ease of Cleaning | Leak Resistance |

|---|---|---|---|

| PEVA | Good | High | High |

| Thinsulate | Very High | Medium | Medium |

Better liners mean longer-lasting cold and less risk of contamination from spills.

Bag Design and Seal Quality

Even the best insulation fails if the bag leaks cold air. Tight seals around openings are critical to stopping warm air from entering.

Seal Options

Zippers, Velcro, and roll-top designs all impact how well a bag traps cold air. Magnetic zippers and gasket-like seals provide excellent closure but may cost more.

| Seal Type | Air Tightness | Ease of Use | Durability |

|---|---|---|---|

| Magnetic zipper | Excellent | High | High |

| Velcro | Moderate | High | Medium |

| Roll-top closure | High | Medium | High |

Adding extra insulation around zippers and seams further reduces convection heat loss.

Environmental Conditions

Where and how you use the cooler bag affects its performance. Temperature, sunlight, and humidity all play a role.

Real-World Effects

Cooler weather helps the bag retain cold longer. Direct sunlight and high heat can reduce performance by up to 30%. High humidity increases condensation inside, which can impact food texture.

| Condition | Effect on Cooling Time |

|---|---|

| Cool, shaded area | +20% performance |

| Direct sunlight | –30% performance |

| High humidity | More condensation inside |

Choosing shaded storage spots and avoiding hot surfaces will help maintain cooling efficiency.

Pre-Cooling and Usage Practices

How you prepare the bag before use can greatly extend cooling time.

Best Practices

Pre-chill the bag by storing it in a cool room or placing ice packs inside before loading food. Freeze drinks or gel packs to lower the starting temperature. Keep the bag closed as much as possible during use.

| Practice | Effect on Cooling Time |

|---|---|

| Pre-chilling bag5 | +1–2 hours |

| Using ice packs | +2–4 hours |

| Keeping bag closed | Prevents quick warming |

Small habit changes can add hours to cold retention.

External Fabric and Durability

The outer material protects the insulation layers and affects how the bag handles moisture and wear.

Fabric Choices

Nylon and polyester6 are common due to water resistance and abrasion durability. A tough outer shell helps prevent punctures that could reduce insulation effectiveness.

| Fabric Type | Water Resistance | Abrasion Resistance | Flexibility |

|---|---|---|---|

| Nylon | High | High | Medium |

| Polyester | High | Medium | High |

The stronger the outer material, the better the insulation will be preserved over time.

Air Pockets and Convection Control

Air trapped inside foam and between bag layers slows heat transfer by convection.

Why Air Matters

Small air pockets work as extra insulation layers. However, too much uninsulated air space inside the bag will allow cold air to escape when opened. A snug fit between items and insulation layers keeps cold air where it’s needed.

| Feature | Effect on Cooling |

|---|---|

| Small air pockets | Better insulation |

| Large empty space | Faster warming |

Pack the bag tightly with items and ice packs to minimize empty space.

Conclusion

Cooler bag insulation works best when quality foam is paired with reflective materials, good seals, and smart usage habits. From my experience supplying insulation bags to overseas buyers, those who pre-cool their bags, keep them shaded, and choose models with tight seals often double the cooling duration compared to casual users. If you have tips or tricks for boosting cooler bag performance, share them in the comments below.

-

Explore this link to discover the top insulation materials that enhance cooler bag performance and keep your items cold longer. ↩ ↩

-

Learn about the advantages of polyurethane foam in cooler bags, ensuring optimal temperature retention and durability. ↩

-

Explore the advantages of EVA foam for insulation, including its lightweight and flexible properties. ↩

-

Learn how polyurethane foam offers excellent insulation and its impact on weight for various applications. ↩

-

Discover how pre-chilling can significantly enhance your cooler's performance and extend cold retention. ↩

-

Learn why these materials are preferred for cooler bags and how they impact durability and insulation. ↩