Canvas bag printing is confusing when you don't know the options. Choosing the wrong method can waste time and money.

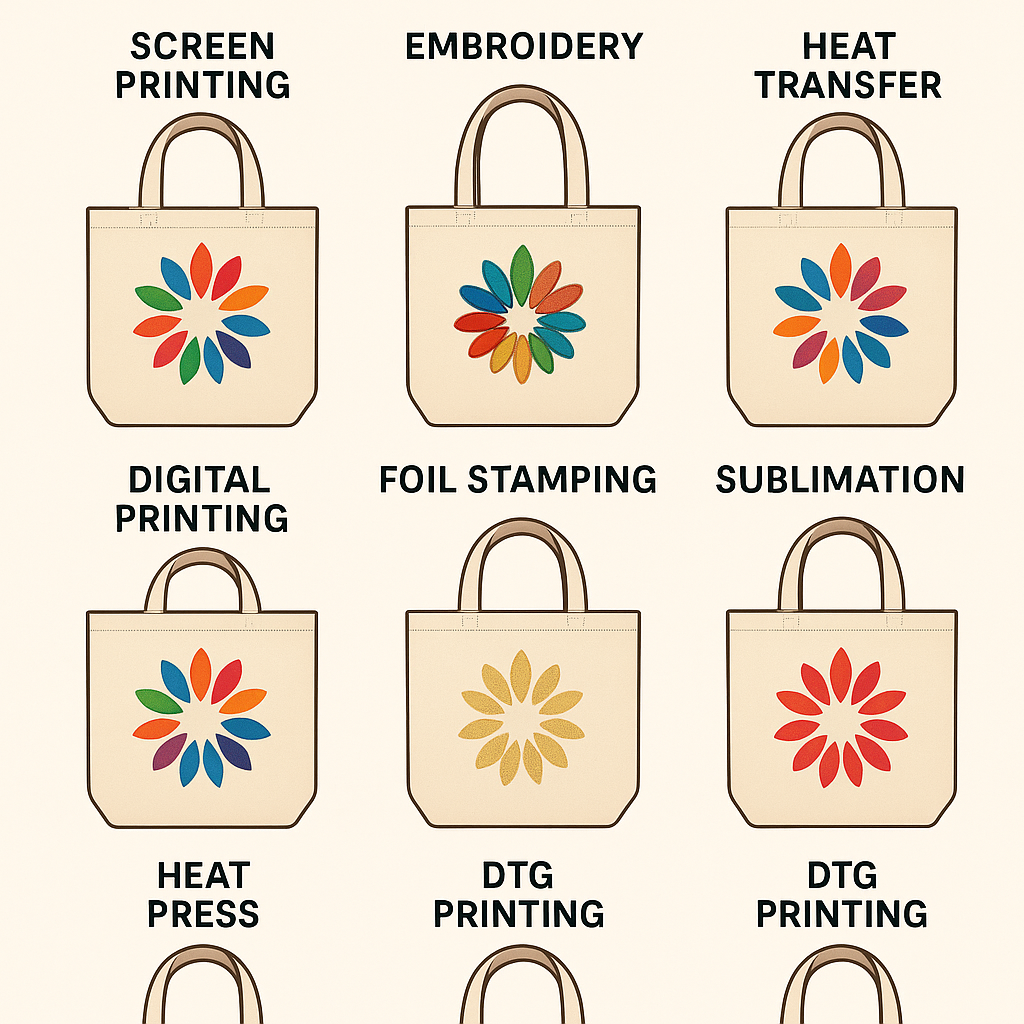

There are eight popular printing methods for canvas bags, each with unique benefits, suitable for different materials, colors, and order sizes.

Each method fits a different business need. Let’s explore these methods so you can make better sourcing decisions.

Which Printing Method Is Best for Large Quantities?

Bulk orders demand a fast, cost-efficient method. If not handled correctly, delays or high costs can ruin profit margins.

Screen printing1 is best for bulk canvas bag orders due to its speed, durability, and low unit cost.

Screen printing works by pressing ink through a mesh stencil. Each color needs a separate screen. This method works best for simple designs and solid colors. I’ve used screen printing when fulfilling orders of over 10,000 bags. It reduced my production cost per unit by more than 40%.

Pros and Cons of Screen Printing

| Feature | Advantage | Disadvantage |

|---|---|---|

| Cost | Very low per unit in bulk | Expensive setup for small runs |

| Durability | Ink deeply bonded to fabric | Limited to solid color designs |

| Color Options | Bright and vivid colors | One screen per color |

Is Digital Printing Suitable for Complex Designs?

Detailed artwork can get ruined by poor printing. I once had an order rejected due to blurry graphics from a cheap process.

Digital printing (DTG) is best for photo-quality images, gradients, and small quantity runs.

Digital printing2 uses inkjet technology. It directly applies the design onto the bag, like a printer on paper. There are no screens or plates. I used DTG when testing out 100 prototype bags for a new client. The clarity was excellent, and I didn’t need to pay for setup.

Use Cases for Digital Printing

| Order Size | Design Type | Fabric Color |

|---|---|---|

| Low | Multi-color logos | Light only |

| Medium | Gradients/photos | White works best |

Can Heat Transfer Handle Small and Detailed Logos?

Some clients need small logos or multi-color artwork. But screen printing won't capture the detail.

Heat transfer works well for sharp, small logos and full-color prints, especially on short runs.

This method prints the image on transfer paper and uses heat to apply it onto the canvas bag. It’s precise and flexible. I used this when one customer ordered 500 promotional bags for a tech expo. Their logo had gradients and tiny text. Heat transfer preserved every detail.

Heat Transfer Breakdown

| Benefit | Notes |

|---|---|

| Fine detail | Great for small logos |

| Full-color options | Ideal for digital art |

| Cost | Mid-range for small runs |

Is Sublimation Printing Good for Canvas Bags?

Sublimation has its limits. If used on unsuitable fabric, it can fail completely.

Sublimation works well only on polyester-blended canvas bags, not on 100% cotton.

Sublimation uses heat to turn dye into gas, bonding it with polymer-based fabric. I once made the mistake of using sublimation on a 100% cotton canvas. The print faded after the first wash. That taught me to check fabric compatibility carefully.

Sublimation Use Guide

| Fabric Type | Result |

|---|---|

| 100% Polyester | Best outcome |

| Cotton/Canvas Mix | Faded or partial |

| 100% Cotton | Not suitable |

Should I Use Embroidery3 for Custom Bags?

Embroidery looks premium, but it isn’t right for every use case.

Embroidery gives a high-end, tactile finish and works best for logos and simple designs.

This method uses thread stitched into the bag’s surface. I once worked with a hotel group that wanted embroidered logos on canvas welcome bags. It gave the bags a premium look and feel. But it increased cost and wasn’t ideal for detailed artwork.

When to Choose Embroidery

| Feature | Suitability |

|---|---|

| Branding | High-end look |

| Longevity | Very durable |

| Complexity | Limited design detail |

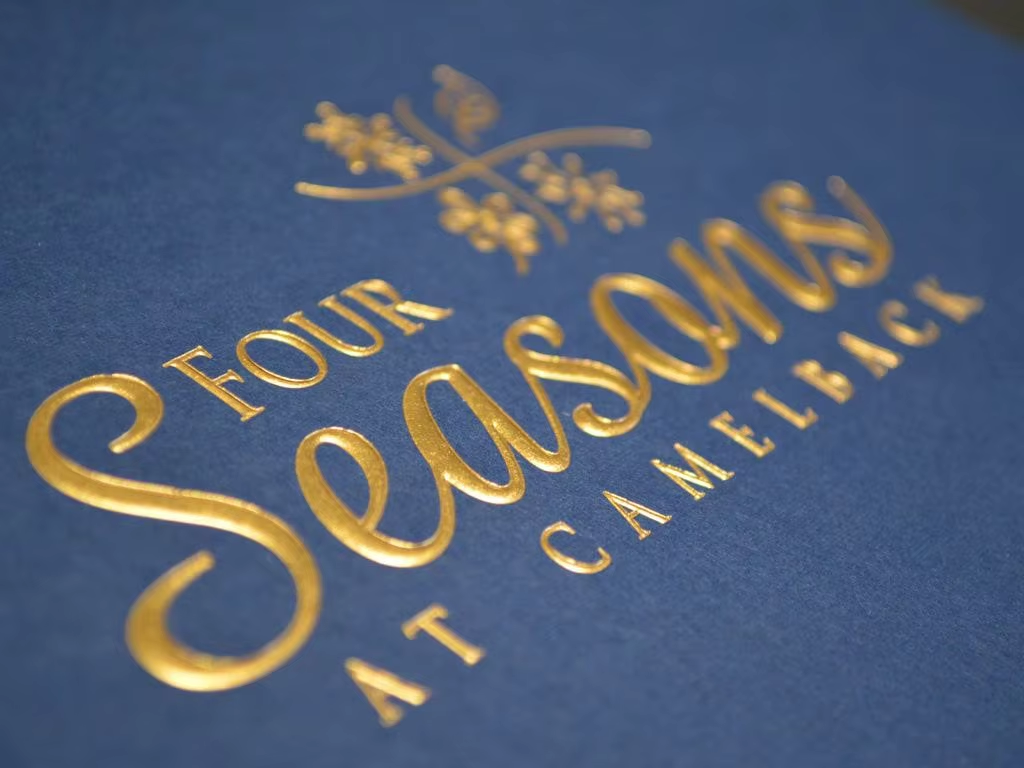

Is Foil Stamping a Good Branding Option?

Some brands want metallic finishes. But these require special methods.

Foil stamping adds metallic shine to logos and names, ideal for luxury branding.

Foil stamping uses a heated die to press metallic foil onto the bag surface. It’s not colorful but very eye-catching. A wine company I worked with used gold foil stamping on gift bags. The bags stood out at retail events and boosted brand visibility.

Foil Stamping Insights

| Element | Description |

|---|---|

| Visual Effect | Metallic, reflective |

| Usage Volume | Low to medium runs |

| Print Area Limit | Best for small areas |

Can UV Printing Work on Canvas Bags?

UV printing feels like magic, but it has specific hardware needs.

UV printing is a high-tech method for small areas and textured prints, mostly used for rigid materials.

UV printing uses ultraviolet light to cure ink instantly. It prints raised or textured designs. While not common for fabric, I’ve seen it used on canvas blends that are stiff and pre-treated. The feel is unique but the cost is high, and the area coverage is limited.

UV Print Summary

| Feature | Result |

|---|---|

| Texture | Raised or embossed |

| Compatibility | Limited to treated fabric |

| Cost | High |

What Is Puff Printing and When Should I Use It?

Puff prints attract attention. But if misused, the result can look bulky or cartoonish.

Puff printing creates raised, soft textures that enhance simple logos or patterns.

It is a variation of screen printing. A special ink expands when heated, creating a 3D texture. A bakery brand I supported used puff ink on a pink canvas bag. The soft, raised logo reflected their friendly image perfectly. It wasn’t suitable for small text but perfect for shapes.

Puff Ink Facts

| Design Type | Effect |

|---|---|

| Bold shapes | 3D, playful texture |

| Small fonts | Can lose clarity |

| Bright colors | Work best |

Conclusion

Each canvas bag printing method suits a specific business need, from low-cost bulk orders to premium, high-detail branding.

Jiarong Packaging supports all 8 printing methods. Customize your exclusive bag now: https://zjjrpackaging.com/

-

Explore the benefits of screen printing for bulk canvas bag orders, including cost efficiency and durability. ↩

-

Learn how digital printing can achieve high-quality, detailed designs on canvas bags, perfect for small runs. ↩

-

Discover why embroidery offers a premium look and durability for branding on canvas bags, ideal for logos. ↩