Many customers are frustrated by poor print results on non-woven bags. The root causes often hide in overlooked details during production.

The screen printing effect of non-woven bags is influenced by material quality, ink selection, mesh size, pressure, drying conditions, and environmental humidity.

Let's explore each factor to find better printing solutions.

Does the material quality of non-woven bags affect screen printing?

Bad material leads to fuzzy or uneven prints. Customers complain when their brand logo fades quickly or doesn’t print clearly.

Material density, surface smoothness, and fiber composition directly impact ink adhesion and overall print clarity.

Dive Deeper: How material properties impact ink behavior

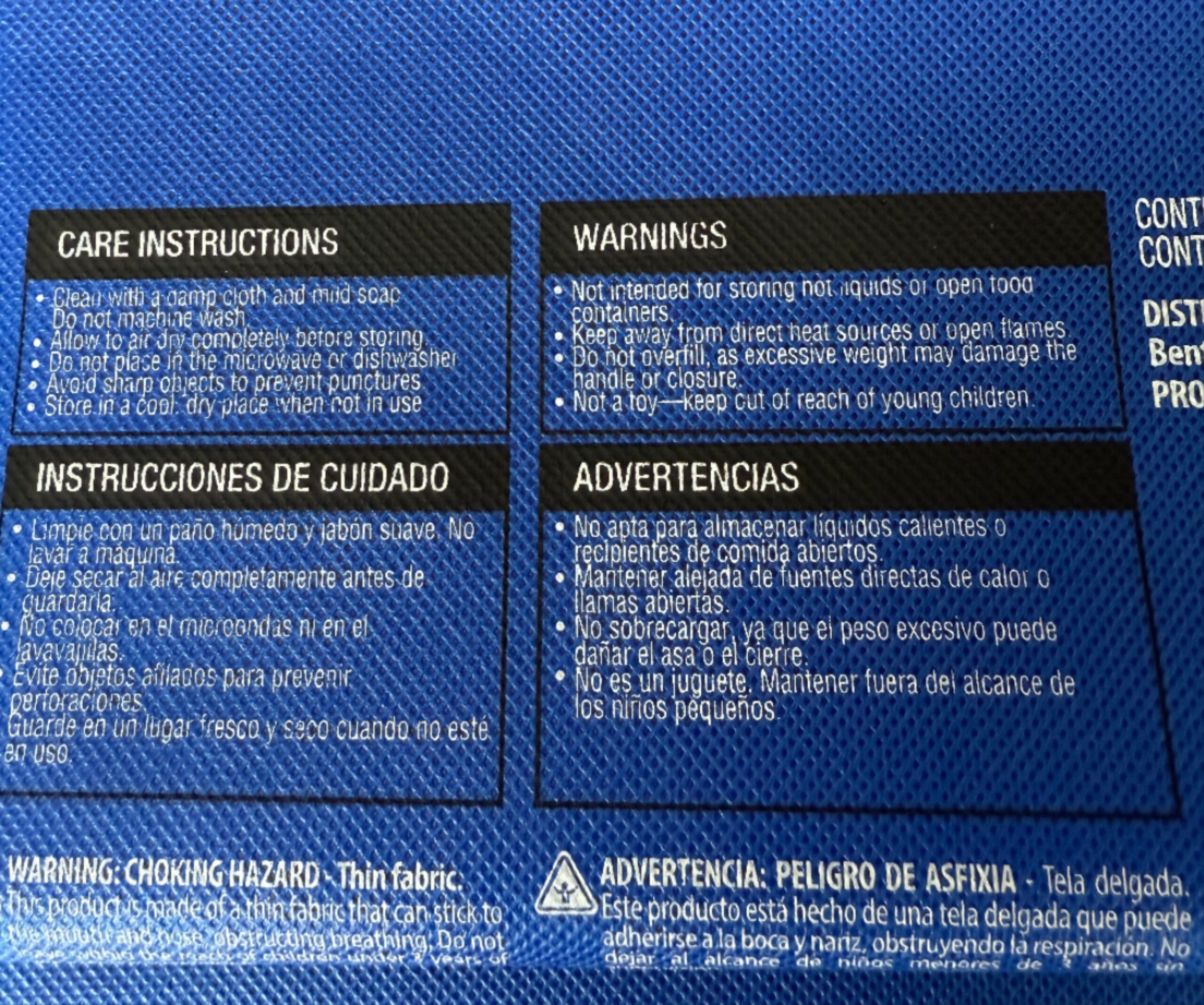

Non-woven fabric varies by type. In our factory, we usually use spunbond non-woven fabric because it has better surface uniformity. This ensures the screen print is more stable and consistent. When customers bring their own materials, we test ink absorption first.

Here's a breakdown of how material types influence printing:

| Material Type | Surface Texture | Ink Absorption | Print Clarity |

|---|---|---|---|

| Spunbond Non-woven | Smooth | Moderate | High |

| Needle-punched Non-woven | Rough | High | Low |

| Laminated Non-woven | Coated/Glossy | Low | Variable |

Rough-textured bags may absorb more ink unevenly. This causes shadows or blur. Laminated bags may resist ink unless treated. So, I always recommend confirming fabric type before bulk printing. I once printed a large order on untreated laminated bags — the ink scratched off with a fingernail.

How does ink choice1 affect printing results?

Using the wrong ink leads to fading or cracking. Some clients complain their bag colors look dull after a few weeks.

Different inks interact differently with non-woven fibers. Plastisol, water-based, and solvent inks each suit different situations.

Dive Deeper: Ink types and their performance on non-woven fabric

We often suggest water-based ink for eco-conscious buyers. But water-based inks dry fast and clog screens. Plastisol ink offers strong color but needs high curing heat. Each option involves trade-offs.

| Ink Type | Adhesion | Flexibility | Eco-Friendly | Drying Needs |

|---|---|---|---|---|

| Water-based | Medium | High | Yes | Fast |

| Plastisol | Strong | Medium | No | Needs curing |

| Solvent-based | High | High | No | Slow |

I once used solvent ink on a 10,000-bag order for a client in Thailand. The color was vibrant and long-lasting, but the smell during production caused complaints from factory workers. Now, we ventilate heavily and choose low-odor ink options.

Does mesh count2 affect print details?

Mesh that's too tight or too loose causes loss of detail. Clients may report their text looks smudged or symbols don’t appear sharp.

The mesh count determines how much ink passes through. Higher mesh is for fine details, lower for bold prints.

Dive Deeper: Choosing the right mesh for the job

The mesh count we choose depends on the artwork design. Detailed logos need fine mesh. For large blocks of color, coarse mesh performs better. For example, 110 mesh is good for simple logos. For tiny text or thin lines, we switch to 160 mesh or higher.

| Mesh Count | Best Use Case | Ink Flow | Detail Level |

|---|---|---|---|

| 80-100 | Large solid areas | High | Low |

| 110-130 | General-purpose logos | Medium | Medium |

| 160-200 | Fine text, intricate art | Low | High |

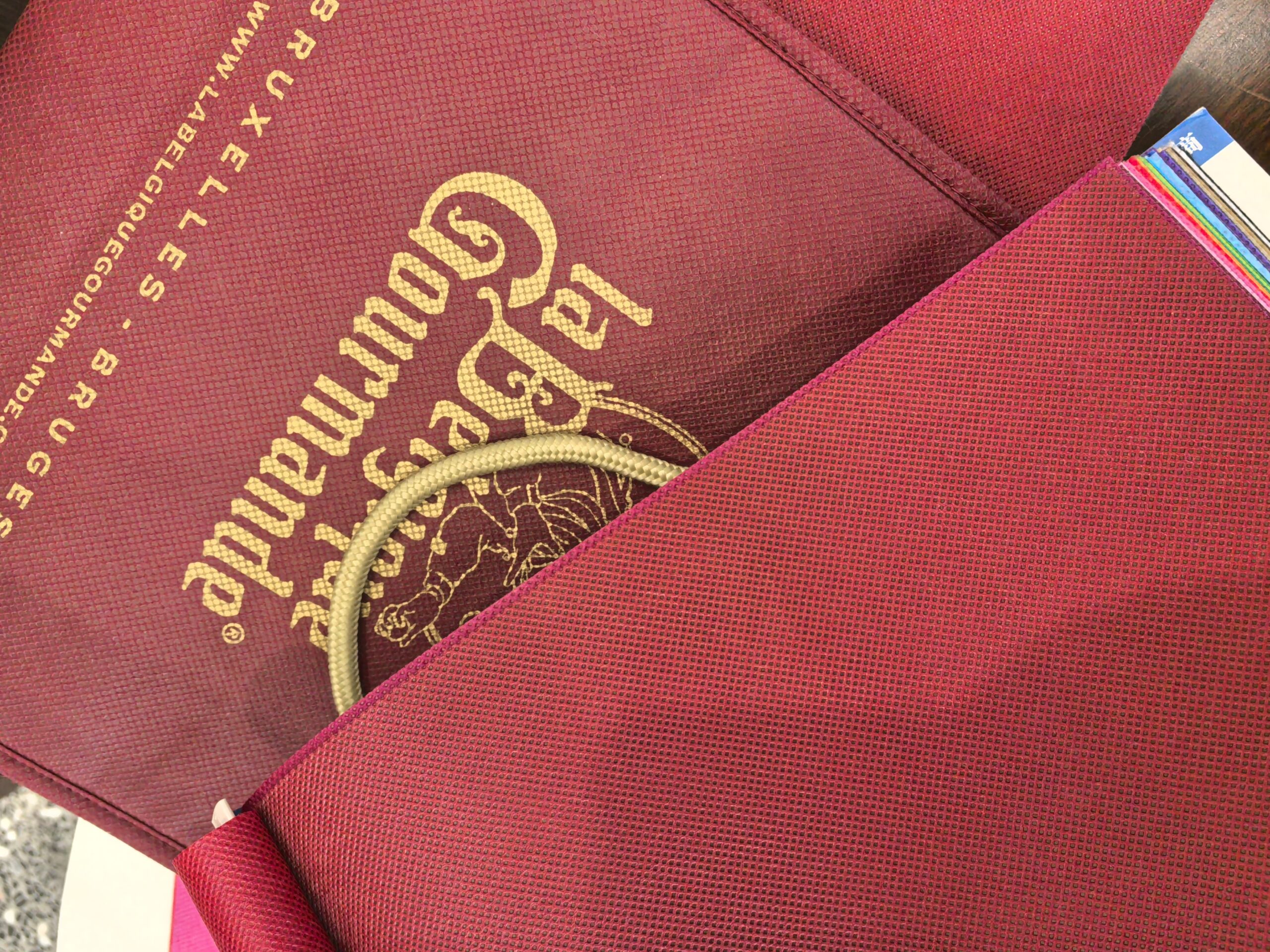

Last year, a client from the US ordered a detailed wine bag logo with gold lettering. We used 180 mesh, and the result was sharp and elegant. Using lower mesh would have bled the details.

Does printing pressure and angle matter?

Uneven pressure creates inconsistent prints. This can cause gaps, overlaps, or double edges in the design.

Incorrect squeegee pressure and angle during screen printing affect ink transfer and image alignment.

Dive Deeper: Adjusting equipment for best results

We train our staff to maintain a 45-degree squeegee angle with consistent pressure. If the angle is too steep, ink builds up and blurs. If too flat, ink may not pass through properly. Pressure must match the ink viscosity.

| Pressure Level | Effect on Ink Spread | Risk |

|---|---|---|

| Too Low | Incomplete transfer | Missing print |

| Ideal | Even transfer | Stable image |

| Too High | Ink bleeding, distortion | Smudged image |

Once, a new operator applied too much pressure on a PP woven bag print run. The result was a distorted logo with feathered edges. We had to reprint 5,000 bags. Since then, we’ve installed pressure regulators on all machines.

How do drying conditions and humidity affect the print?

In humid conditions, drying time increases. This can smear prints or trap moisture. It ruins the final finish.

Drying temperature and humidity affect ink curing and adhesion. Inadequate drying causes flaking or color fading.

Dive Deeper: Managing environment during production

Our factory maintains controlled temperature and airflow. Drying tunnels speed up curing. Humidity above 60% slows drying. We pause production if the humidity gets too high during monsoon seasons. That helps avoid ink smearing and bag sticking issues.

| Condition | Result | Risk |

|---|---|---|

| High humidity | Slow drying, blurred lines | Ink smudging |

| Low humidity | Fast drying, better detail | Screen clogging |

| High heat | Proper curing | Warped material |

| Low heat | Incomplete curing | Faded or flaked print |

During a batch for a European distributor, we had to adjust our drying time after noticing some prints began to flake. We extended the heating cycle and added air blowers, which fixed the issue.

Conclusion

Screen printing quality depends on the right material, ink, mesh, pressure, and drying. Managing each step well ensures reliable and vivid results.

At JiaRong Packing, we are equipped with advanced one-time three-color screen printing machines that ensure fast, high-quality, and multi-color prints on non-woven bags. If you're looking for professional printing services and customized packaging solutions, visit our website and contact us today!