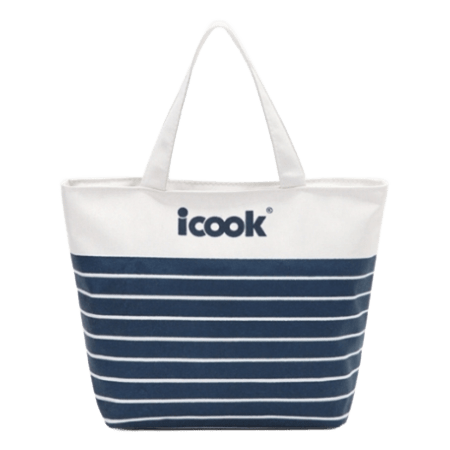

At JiaRong Packaging, we specialize in producing premium-quality nylon bags designed to meet your business needs. Durable, lightweight, and versatile, our nylon bags are perfect for a variety of applications, from shopping to promotional events.

Not sure about your custom-crafted nylon bag needs or have a unique idea in mind? Let’s discuss! Our experienced team is here to guide you through the process, ensuring the design and creation of nylon bags that perfectly align with your business requirements. With your vision and our expertise, we’ll work together to deliver the ideal solution.

As a professional custom-crafted nylon bag manufacturer, we offer fully customizable services, including size, color, logo printing, and additional features. Whether you need nylon bags for retail, promotions, or events, we’ve got you covered!

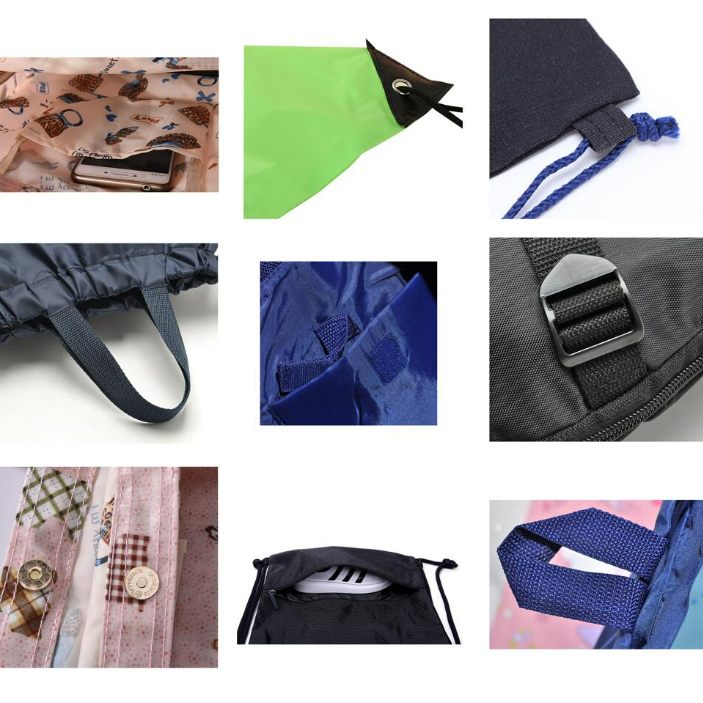

Size Customization We offer various bag sizes tailored to your specific needs for different purposes.

Color Options Choose from a wide range of colors to match your brand identity or event theme.

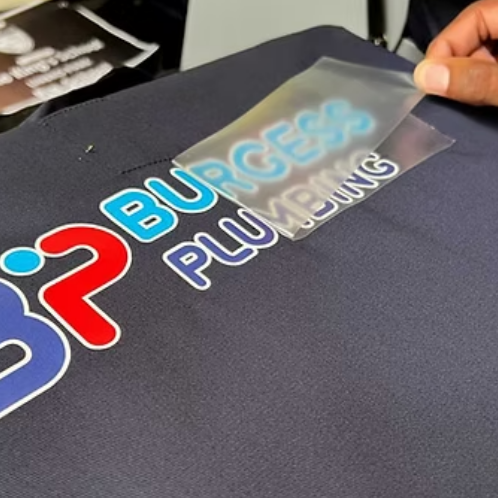

Printing Design High-quality printing for logos, slogans, or designs, ensuring vibrant and durable results.

Material Thickness Multiple thickness options are available to suit different load capacities and usage scenarios.

Bag Structure Options include box-like designs, reinforced bottoms, side gussets, handles, and zippers.

Special Features Add waterproof coatings, dustproof layers, or eco-friendly biodegradable materials.

Packaging Requirements Individual packaging, bundled packing, or custom cartons to meet your logistics and display needs.

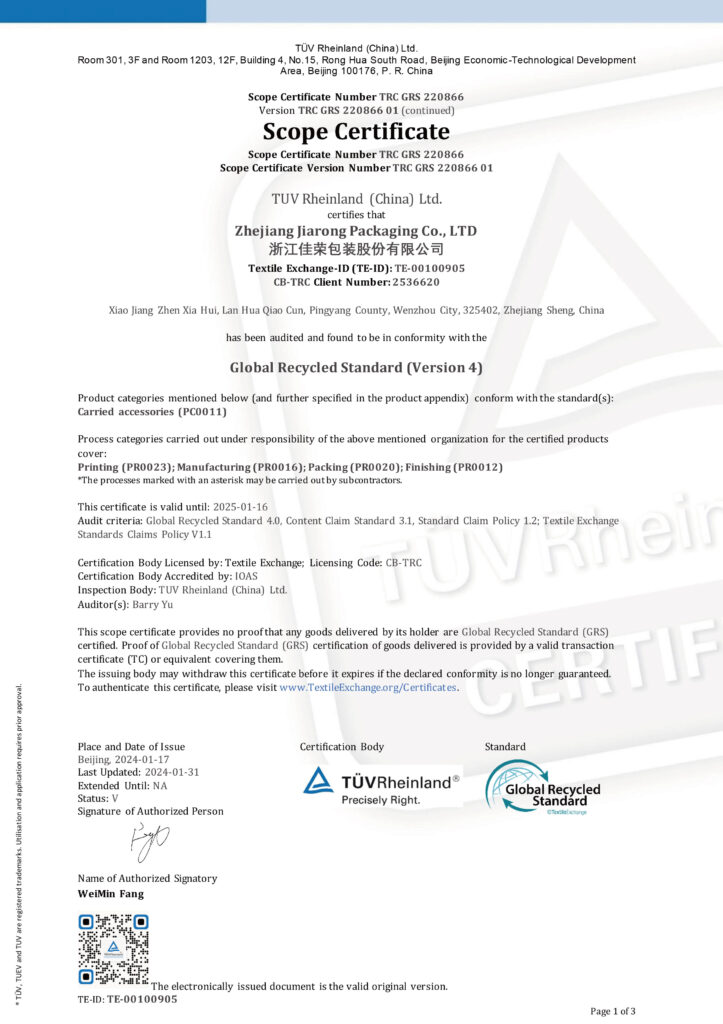

Our product range includes more than just standard packaging solutions. We specialize in high-quality Nylon Bags, along with other eco-friendly options such as PP woven shopping bags and aluminum foil insulated bags. Our Nylon Bags are designed with durability, style, and sustainability in mind, making them perfect for various applications. We prioritize timely delivery, exceptional product quality, and fully customized designs to meet the specific requirements of your business. This dedication to excellence has earned us a strong and trusted reputation in the packaging industry.

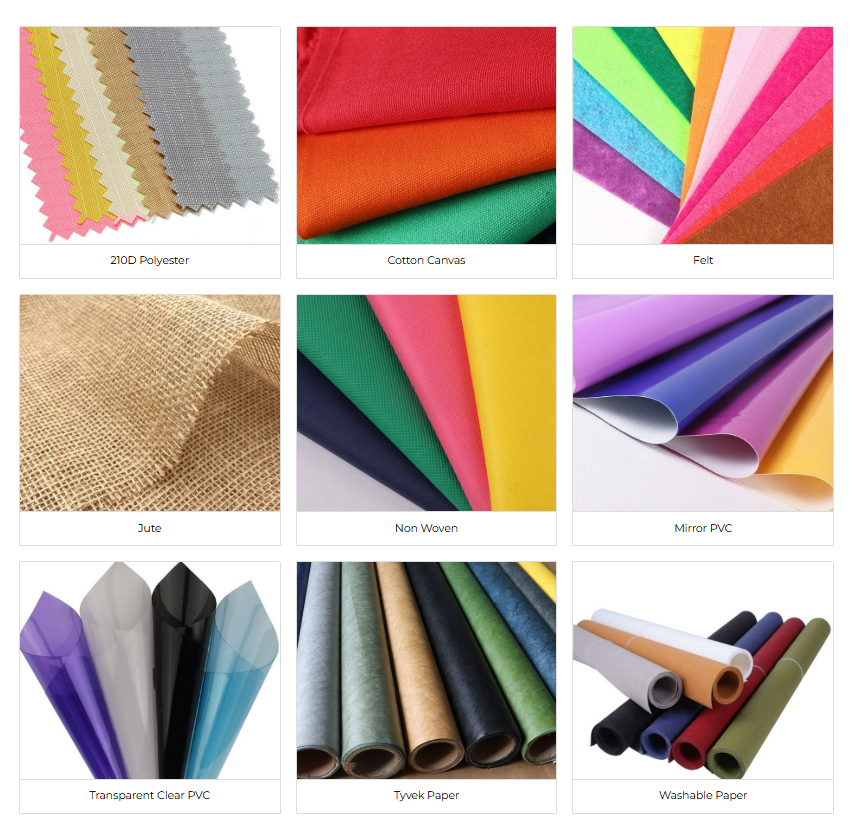

Wide Selection of Materials

We offer a diverse range of materials for your packaging needs, including PP woven fabric, non-woven fabric, canvas, aluminum foil, and more. Each material is carefully selected to provide the perfect balance of durability, eco-friendliness, and style.

Diverse Product Lineup

We offer a broad range of packaging solutions to meet the varying needs of your business. From PP woven shopping bags, non-woven bags, and canvas bags to aluminum foil insulated bags, we provide durable and eco-friendly options for every occasion.

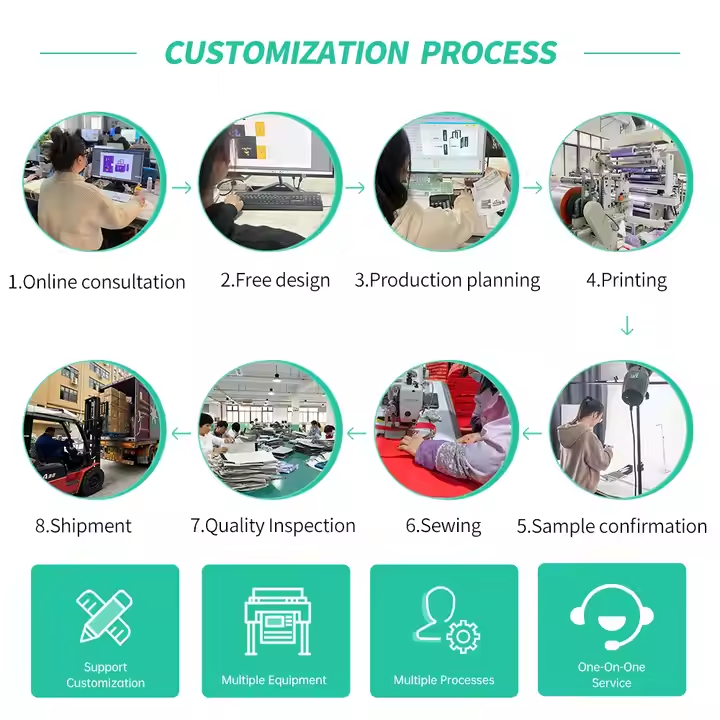

Fabrication and Machining

With years of expertise in the packaging industry, trust us to carefully craft and customize your non woven shopping bags to meet your exact specifications. Our experienced team uses advanced machinery and techniques to ensure precision, durability, and a flawless finish, delivering packaging solutions that perfectly align with your brand and business requirements.

Unmatched Technical Support

If you have any questions about our products or services, we’re here to help. Whether you need advice based on previous projects or require on-site assistance with your packaging needs, our team is ready and equipped to provide the support you need. We are committed to ensuring that your experience with us is smooth and that you receive the best possible solution for your business.

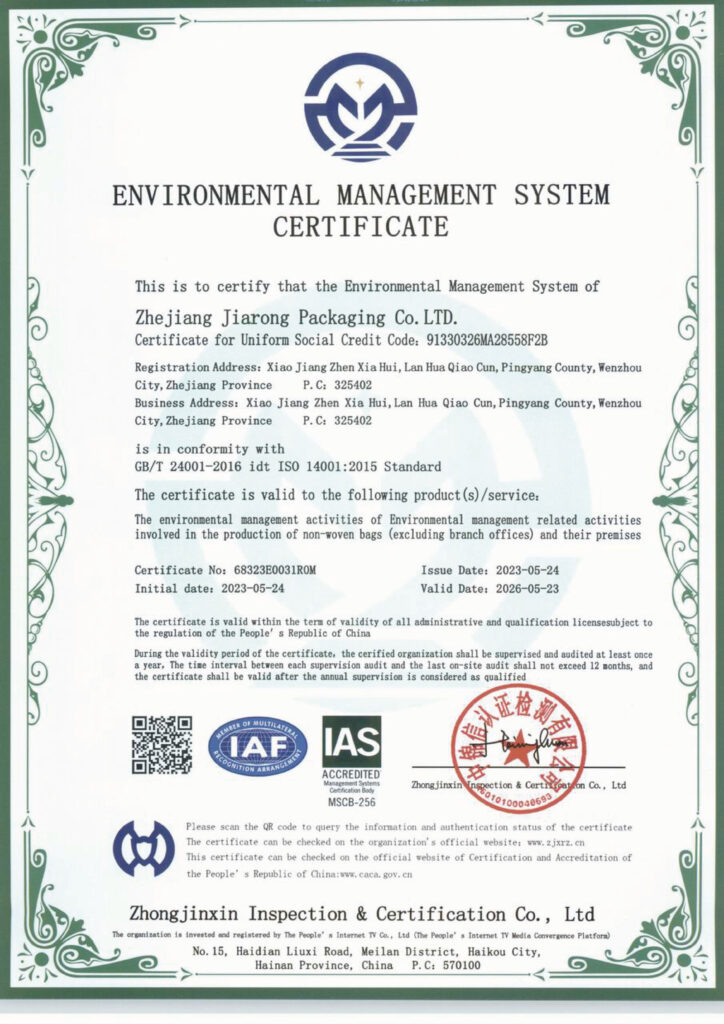

JiaRong Packaging has been dedicated to providing high-quality, customizable eco-friendly packaging solutions for years. We produce a wide range of bags, including Canvas bag, non-woven bags, PP woven bags, and gift bags, ensuring each product meets your specific needs. Choose JiaRong Packaging for superior quality and reliable service that will support your business success.

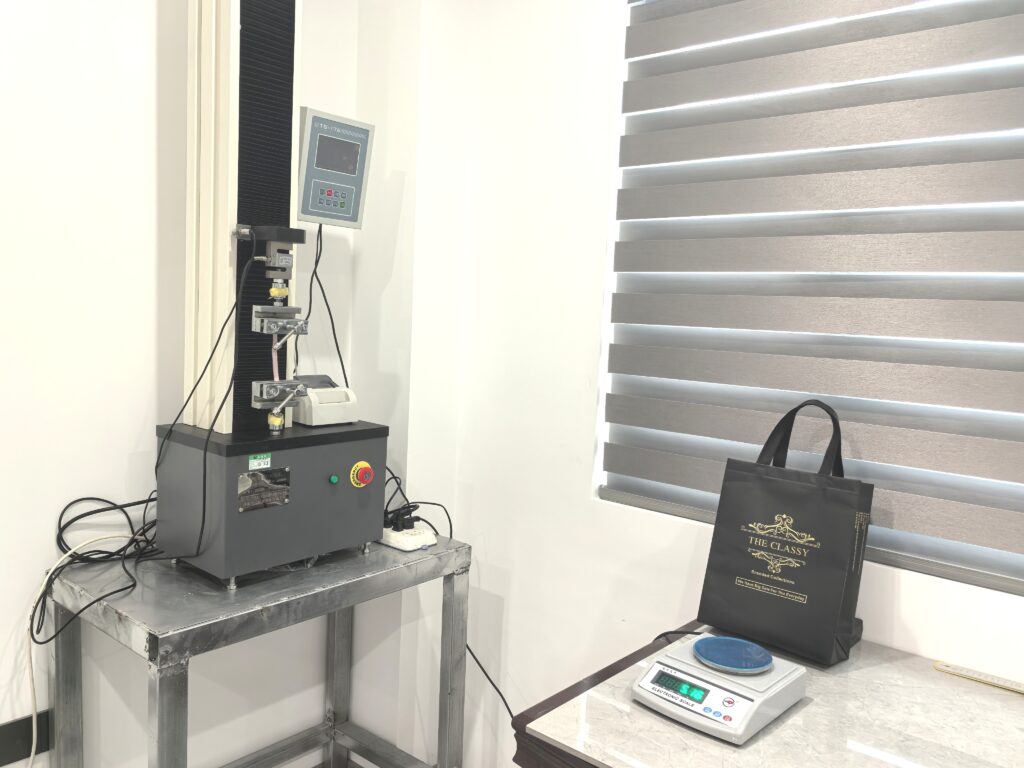

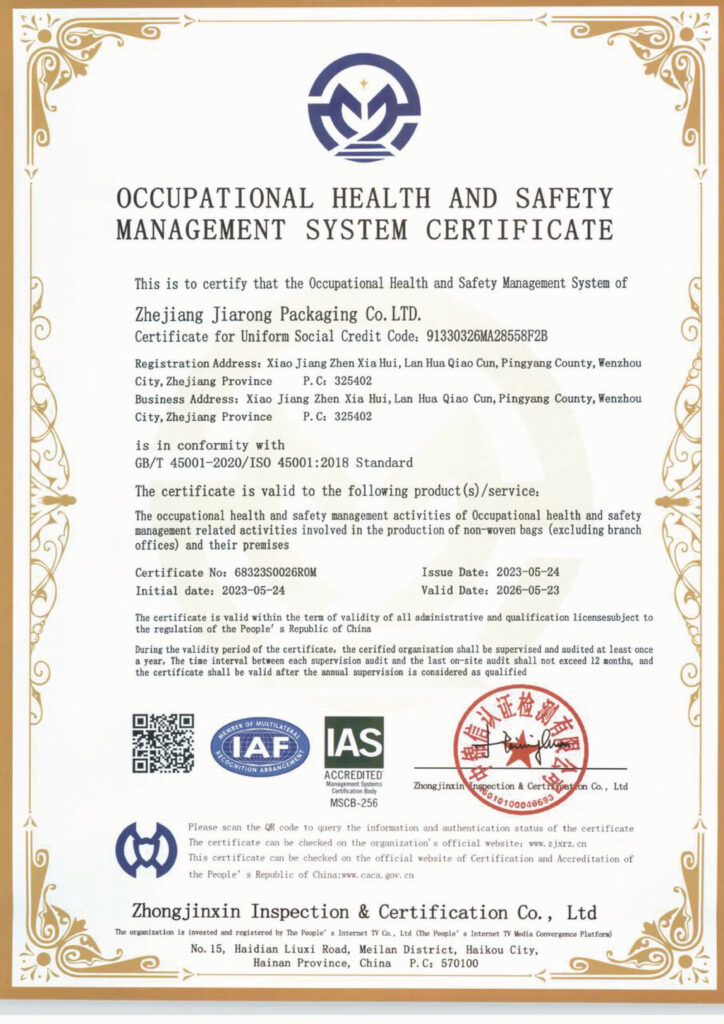

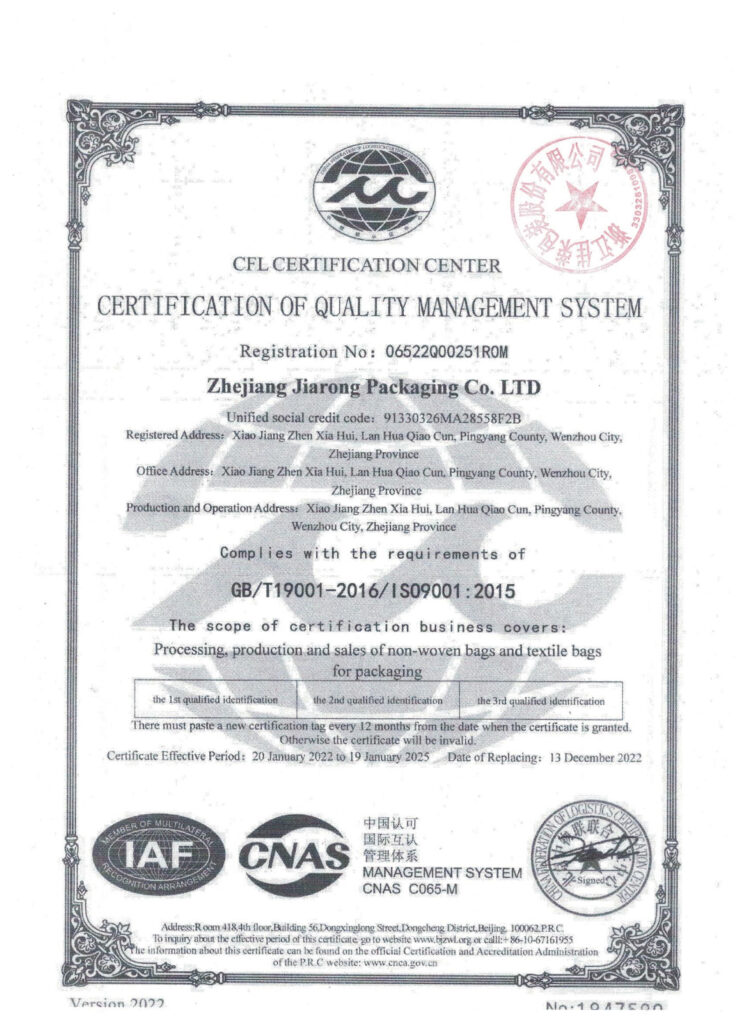

Worried about product quality? JiaRong Packaging is ISO 9001:2015 certified, ensuring every product meets international standards for consistent and reliable quality.

Concerned about production limits? With over 16,000 square meters of factory space and advanced equipment, we can handle orders of any size, from small batches to large-scale production.

Need a variety of packaging solutions? We offer a wide range of bags including Cotton Bags ,non-woven bags, PP woven bags, aluminum foil insulation bags, and more, catering to supermarkets, hotels, restaurants, and various industries.

Unsure about quality? We enforce stringent quality control at every stage, from raw material sourcing to final production, ensuring every product meets the highest standards.

Looking for a reliable partner? JiaRong Packaging has earned multiple honors, including the “Industrial Science and Technology Innovation Award” and “AAA Credit Enterprise,” reflecting our strength and credibility.

Planning to expand globally? Our products are exported to Europe, the U.S., Asia, and other regions, giving you the confidence of working with a partner equipped for international markets

Nylon Bags are a versatile, eco-friendly, and popular choice for businesses and consumers alike. Whether you’re sourcing them for retail, promotions, or as reusable alternatives to single-use plastic bags, this guide will help you navigate the process of procuring the perfect Nylon Bags for your needs.

A nylon bag is a type of bag made from nylon, a durable, lightweight, and versatile synthetic material. Nylon bags are widely used due to their practicality, resistance to wear and tear, and adaptability for various applications.

Key Features of Nylon Bags:

Common Uses:

Nylon bags are a versatile solution for both personal and business needs, offering a blend of practicality and style.

Nylon bags are crafted from nylon, a synthetic polymer known for its exceptional durability, flexibility, and lightweight properties. Nylon was first developed as a substitute for silk and has since become a popular material for various applications, including bags.

Key Properties of Nylon Material:

Types of Nylon Used in Bags:

Nylon’s versatility makes it a preferred material for bags used in shopping, travel, sports, promotions, and more. Its ability to combine durability with a sleek design ensures it meets the needs of both functionality and aesthetics.

.

The nylon fabric is cut into pieces according to the desired bag dimensions and design.

Each bag undergoes thorough inspection to ensure it meets durability, size, and design standards. Any defective items are identified and corrected.

By combining cutting-edge machinery and strict quality control, manufacturers like JiaRong Packaging ensure that every nylon bag produced meets the highest industry standards.

📩 Contact us for more details on how we manufacture premium nylon bags customized to your needs!

Printing on drawstring bags is a key step in customization, allowing businesses to add logos, designs, or branding to the bags. Below is an overview of the most common printing processes used:

| Printing Method | Process | Features | Best For |

|---|---|---|---|

| Screen Printing | Ink is pushed through a stencil on a mesh screen onto the nylon surface. | Cost-effective for large batches. – Vibrant colors and durable. – Simple designs with fewer colors. | Logos, slogans, or basic graphics. |

| Heat Transfer Printing | Design is printed on transfer paper and heat-pressed onto the nylon bag. | – High-quality and precise printing. – Supports complex and multicolor designs. – Suitable for small batches. | Detailed or photographic designs. |

| Sublimation Printing | Dye is heat-transferred to nylon, bonding with fabric fibers. | – Long-lasting, vivid prints. – Best on white/light-colored nylon. – Limited to polyester-coated nylon. | Graphics with gradients and textures. |

| Digital Printing | Inkjet or laser technology applies design directly to the nylon surface. | – Ideal for short runs and rapid production. – Handles intricate, multicolor designs. – Slightly less durable. | Custom or on-demand prints. |

To enhance the functionality, aesthetics, and durability of drawstring bags, several additional processes can be applied during manufacturing. These processes add value and ensure the bags meet specific business and user requirements.

Drawstring is the biggest feature of this kind of bag. You have a number of options for it, including cotton rope, polyester rope and PP rope. If liking firmer and thicker ones, you can also choose a PP woven belt.If you prefer the same material as the body of the bag, we can also implement it for you.

Nylon bags come in a wide range of styles and sizes, designed to suit various applications and customer needs. Below are some popular styles and their typical dimensions:

Durability

Lightweight

Water-Resistant

Customizable

Eco-Friendly Options

Affordable

Versatile Applications

Environmental Impact

Heat Sensitivity

Moisture Absorption

Static Electricity

Color Fading

The cost of nylon bags can vary based on multiple factors, including material, design, and production methods. Understanding these elements can help you make informed decisions when purchasing nylon bags for your business.

Material Quality

2. Bag Size and Thickness

3. Design Complexity

4. Printing Method

6. Labor and Production Location

7. Additional Features

8. Shipping and Logistics

B2B clients purchasing nylon bags often encounter challenges related to production, customization, quality, and logistics. Identifying these issues and implementing solutions ensures a smoother process and better outcomes.

By understanding and addressing these common issues, B2B clients can ensure a seamless procurement process for nylon bags. Selecting the right supplier, planning effectively, and maintaining open communication are key to overcoming challenges.

📩 Contact us today to experience hassle-free solutions tailored to your nylon bag needs!

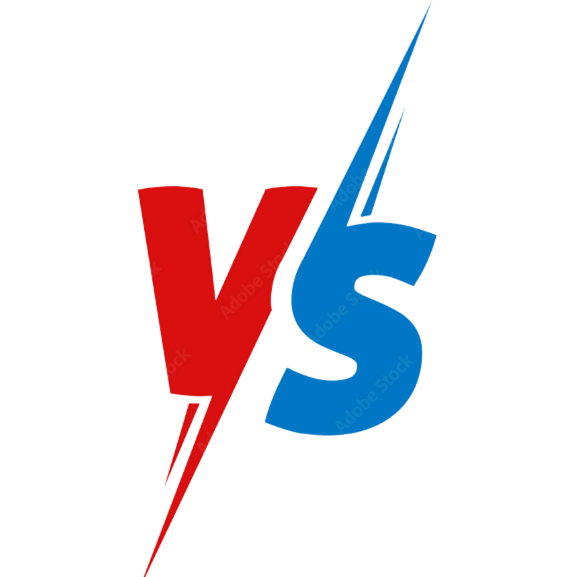

| Aspect | Nylon Bag | Polyester Bag |

|---|---|---|

| Material Strength | Stronger and more abrasion-resistant. | Durable but less strong compared to nylon. |

| Weight | Lightweight and easy to carry. | Slightly heavier than nylon but still portable. |

| Water Resistance | Highly water-resistant, absorbs less moisture. | Water-resistant but absorbs slightly more moisture. |

| UV Resistance | Moderate resistance; may fade over prolonged exposure. | Excellent UV resistance; resists fading better. |

| Texture | Smooth and glossy finish. | Slightly rougher texture. |

| Durability | Long-lasting and withstands heavy use. | Durable but less resistant to wear and tear. |

| Cost | More expensive due to higher-quality properties. | Generally more affordable than nylon. |

| Eco-Friendliness | Can be recycled; more eco-friendly options available. | Also recyclable; increasingly eco-conscious. |

| Best Uses | Heavy-duty bags, backpacks, and water-resistant needs. | Promotional bags, tote bags, and UV-exposed items. |

Purchasing Nylon Bags requires careful planning and clear processes to ensure cost-efficiency, quality, and timely delivery. Here’s a step-by-step guide to streamline the procurement process:

By following these steps, businesses can ensure a smooth procurement process and secure high-quality Nylon Bags at competitive prices. At JiaRongPackaging, we offer professional manufacturing services, reliable quality control, and tailored solutions to meet your procurement needs. Contact us today to get started!

Printing plays a key role in cooler bag customization1. Companies use different methods depending on design complexity2, fabric type, cost, and durability3. Understanding the main

Cooler bags are popular for shopping, outdoor activities1, and food delivery2, but many buyers misunderstand the materials used in their construction. This article clears up

Cooler bags are essential in daily life, from picnics and camping to supermarket shopping and food delivery. Selling them globally requires smart distribution strategies that

The European cooler bag market1 in 2025 shows strong demand for stylish, multifunctional, and durable designs. In this article, we explore six popular cooler bag

Cooler bags are no longer just picnic accessories. They have become daily essentials for professionals, families, and outdoor enthusiasts. In this article, we explore seven

Understanding lead times1 for custom bulk orders is key to planning ahead. This article explains standard production2 timelines, fast options, and factors that affect delivery

Contact us for a free quote and more expertise on custom tote bags. Together with Jiarong Packaging, we will find the right solution for your project.

At Jiarong Packaging, we make it simple! Follow these 3 steps to get started today!

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

We will start mass production after getting your approval and deposit, and we will handle the shipment.

Jiarong Packaging - Non-woven and Insulated Bag Manufacturer

Typically replies within minutes

Any questions related to Nylon Bag?

WhatsApp Us

🟢 Online | Privacy policy

WhatsApp us

We’ll reach out to you within 8 hours. Please keep an eye out for an email from us, coming from the address ending in “@zjjrpackaging.com”

Don’t go away, there are free samples available here. Please leave your email address so I don’t miss you. We’ll reach out to you within 12 hours. Please keep an eye out for an email from us, coming from the Jiarong Packing.