What Printing Methods Are Commonly Used on Cooler Bags?

Printing plays a key role in cooler bag customization1. Companies use different methods depending on design complexity2, fabric type, cost, and durability3. Understanding the main

It is not easy to introduce all aspects of custom package, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

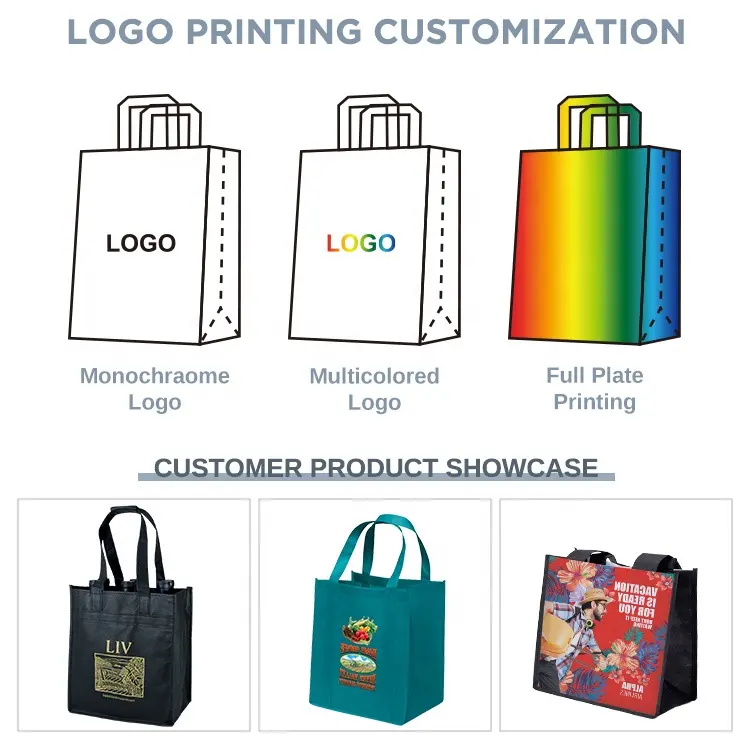

As one of the best professional shopping bag manufacturer, JiaRong Packaging not only produce shopping bag, but also zipper bag, drawstring bag, cosmetic bag, backpack and any other promotion bag, retail bag.

At JiaRong Packaging, we specialize in manufacturing a wide range of high-quality, non-woven bags and related products. Our main product offerings include:

Large capacity, easy folding and reusability are the three main advantures of shopping bag.

Non-woven bags are biodegradable, reducing plastic pollution and supporting sustainability.

PP woven bags made from polypropylene material, with high tensile strength and abrasion resistance.

Keeps items cold or hot for extended periods, ideal for transporting food and beverages.

The drawstring design allows for quick and convenient opening and closing.

Paper bags are biodegradable, reducing environmental pollution and supporting sustainability.

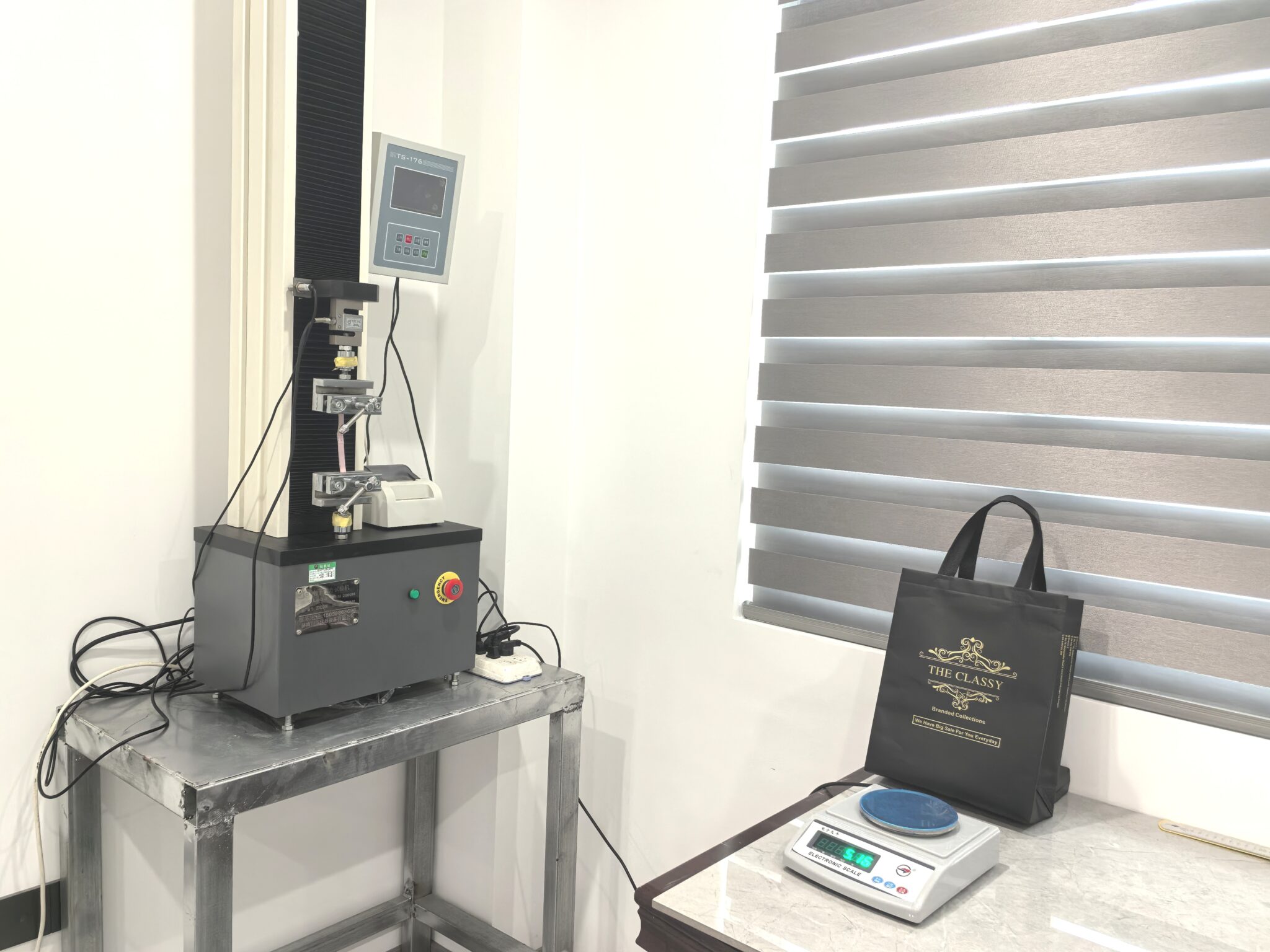

Made from high-quality materials, capable of carrying heavier items and ensuring safe delivery.

Helps organize items and maximizes space, keeping your environment tidy.

Can be used repeatedly, reducing the need for single-use plastic bags and supporting environmental sustainability.

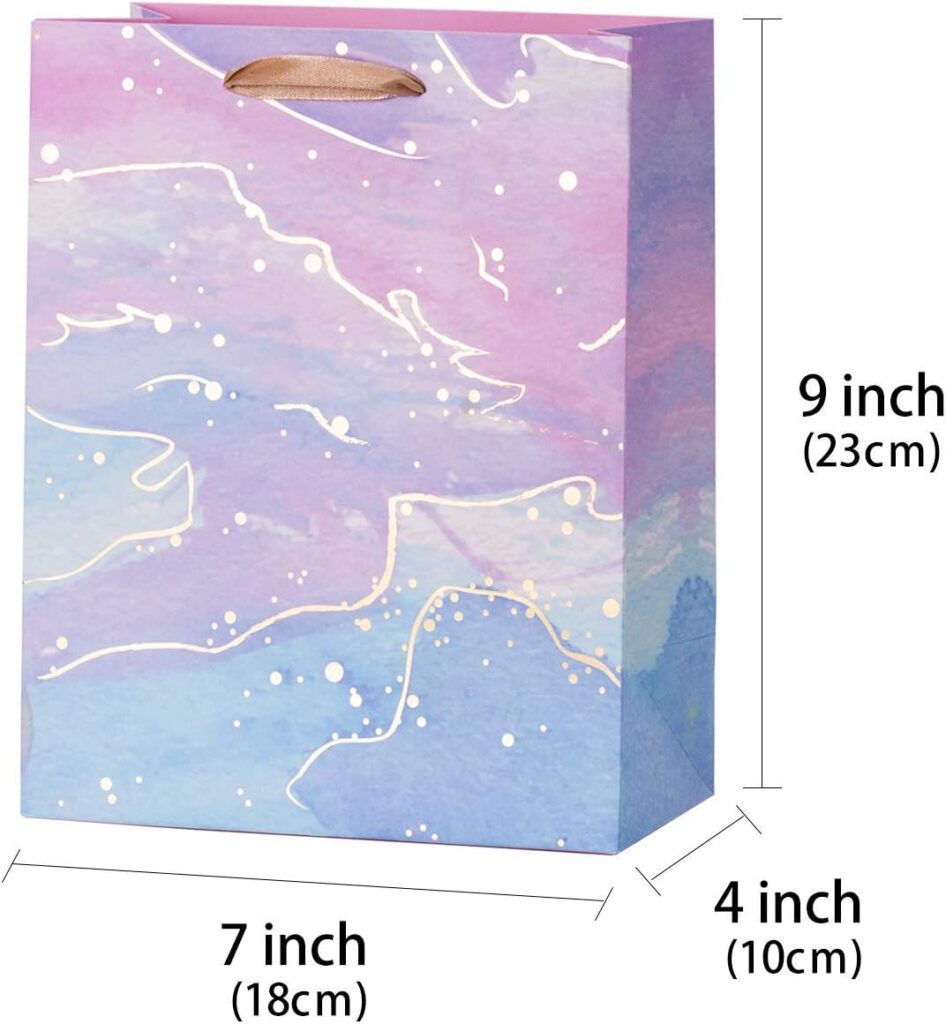

Different types of bags have different common sizes

Use: Suitable for everyday shopping, moderate capacity, easy to carry.

Use: Commonly used for packaging clothing, cosmetics, books, and more, ideal for brand display.

Use: Used for food delivery, with insulation and waterproof design.

Use: Used to replace plastic bags, suitable for daily shopping, promoting sustainability.

Use: For backpack-style designs, ideal for travel, sports, and more.

Use: Ideal for small gift packaging, commonly used for holidays or promotions.

The process of creating custom bags typically involves several key steps, from selecting raw materials to final quality checks. Below is an outline of the standard production process for custom bags:

These formats are ideal because they are scalable without losing quality, ensuring your design looks sharp at any size.

The ordering process for custom bags typically involves several key steps, from initial inquiry to final delivery. Here’s a breakdown of the standard process and the timeframes you can expect at each stage:

Printing plays a key role in cooler bag customization1. Companies use different methods depending on design complexity2, fabric type, cost, and durability3. Understanding the main

Cooler bags are popular for shopping, outdoor activities1, and food delivery2, but many buyers misunderstand the materials used in their construction. This article clears up

Cooler bags are essential in daily life, from picnics and camping to supermarket shopping and food delivery. Selling them globally requires smart distribution strategies that

The European cooler bag market1 in 2025 shows strong demand for stylish, multifunctional, and durable designs. In this article, we explore six popular cooler bag

Cooler bags are no longer just picnic accessories. They have become daily essentials for professionals, families, and outdoor enthusiasts. In this article, we explore seven

Understanding lead times1 for custom bulk orders is key to planning ahead. This article explains standard production2 timelines, fast options, and factors that affect delivery

Below you can find some frequently asked questions regarding custom packaging and print. Please feel free to contact us if you have any other questions.

Most of the custom packaging and print are produced in our own factory in China. For some special products, we will also outsource with our vetted network of suppliers to meet your requirements.

It depends! Typically, the minimum order quantity for custom complex printed machine-molded bags is 3,000 units, and the minimum order quantity for sewn bags with simple printing processes is 1,000 units. We can also accept smaller quantities, but the unit price will be higher.

Definitely! We offer a variety of sample types. We’ve got everything you need to check your artwork for printing or determine the size of your packaging.

Most orders are processed within 15 days, and large orders are delivered within 20-30 days. If you have urgent needs, you can also place an expedited order.

Depending on the method of transportation, air freight can take 5-7 days, and ocean freight can take 15-35 days. Your shipment can be split between air and ocean if you need some packaging expedited sooner!

Yes, we provide dieline design, artwork design, and structural design services. Dieline design is free of charge, but the artwork and structural design will come at a specific cost. Learn more about our design service now!

Contact us for a free quote and more expertise on custom tote bags. Together with Jiarong Packaging, we will find the right solution for your project.

At Jiarong Packaging, we make it simple! Follow these 3 steps to get started today!

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

We will start mass production after getting your approval and deposit, and we will handle the shipment.

Jiarong Packaging - Non-woven and Insulated Bag Manufacturer

Typically replies within minutes

Any questions related to Custom Bag?

WhatsApp Us

🟢 Online | Privacy policy

WhatsApp us

We’ll reach out to you within 8 hours. Please keep an eye out for an email from us, coming from the address ending in “@zjjrpackaging.com”

Don’t go away, there are free samples available here. Please leave your email address so I don’t miss you. We’ll reach out to you within 12 hours. Please keep an eye out for an email from us, coming from the Jiarong Packing.