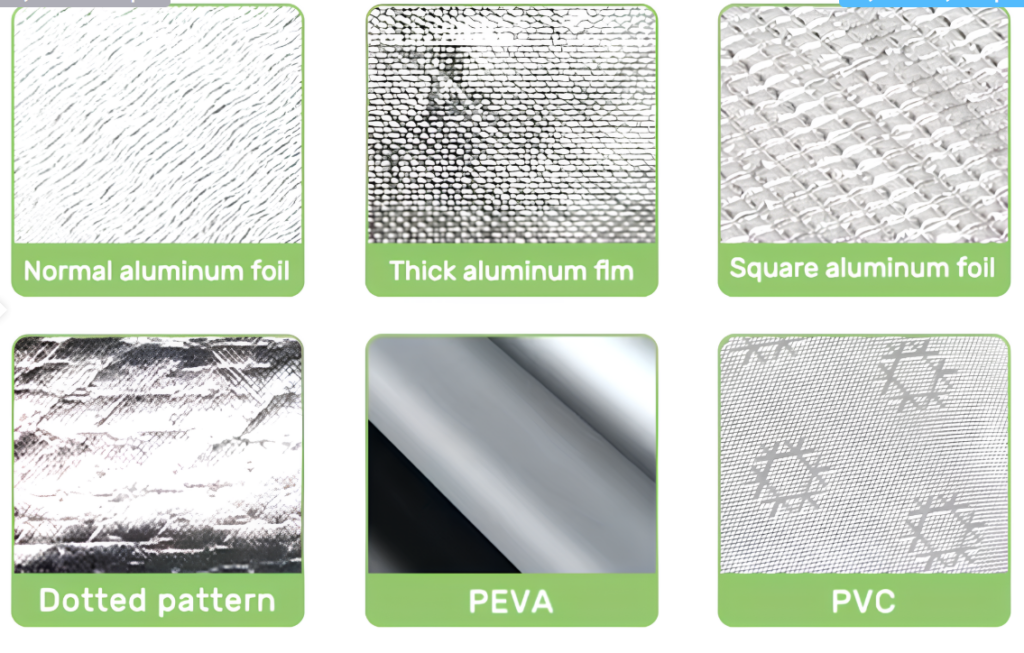

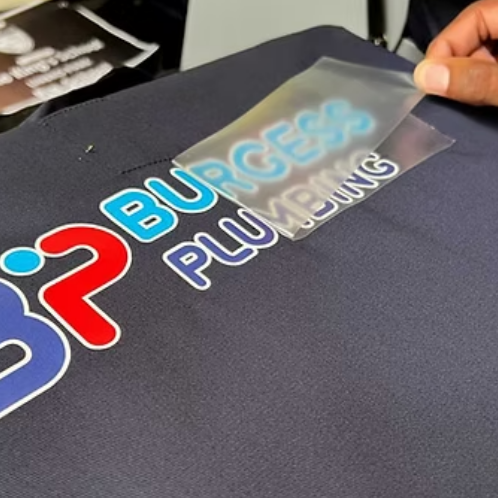

Our Multifunction Oxford Cooler Bags combine practicality, durability, and excellent insulation to meet your daily and business needs. Made from high-quality Oxford fabric, these bags are lightweight, water-resistant, and designed to keep food and drinks at the perfect temperature. Customizable with your logo and preferred specifications, they are an ideal choice for branding.

Applications

- Outdoor activities like picnics, hiking, and beach trips

- Meal delivery services requiring reliable insulation

- Corporate gifts to showcase your brand

- Daily use for work, school, or gym