Maintaining a reliable cold chain is vital for transporting temperature-sensitive products like food, vaccines, and chemicals. Cooler bags play a key role by offering advanced features that boost efficiency and ensure product quality throughout the journey.

6 Ways Cooler Bags Improve Cold Chain Efficiency

Cooler bags enhance cold chain efficiency through superior insulation, effective sealing, advanced cooling methods, portability, durability, and smart pre-chilling strategies.

Reliable cold chain solutions protect valuable goods. Learn how cooler bags make this possible.

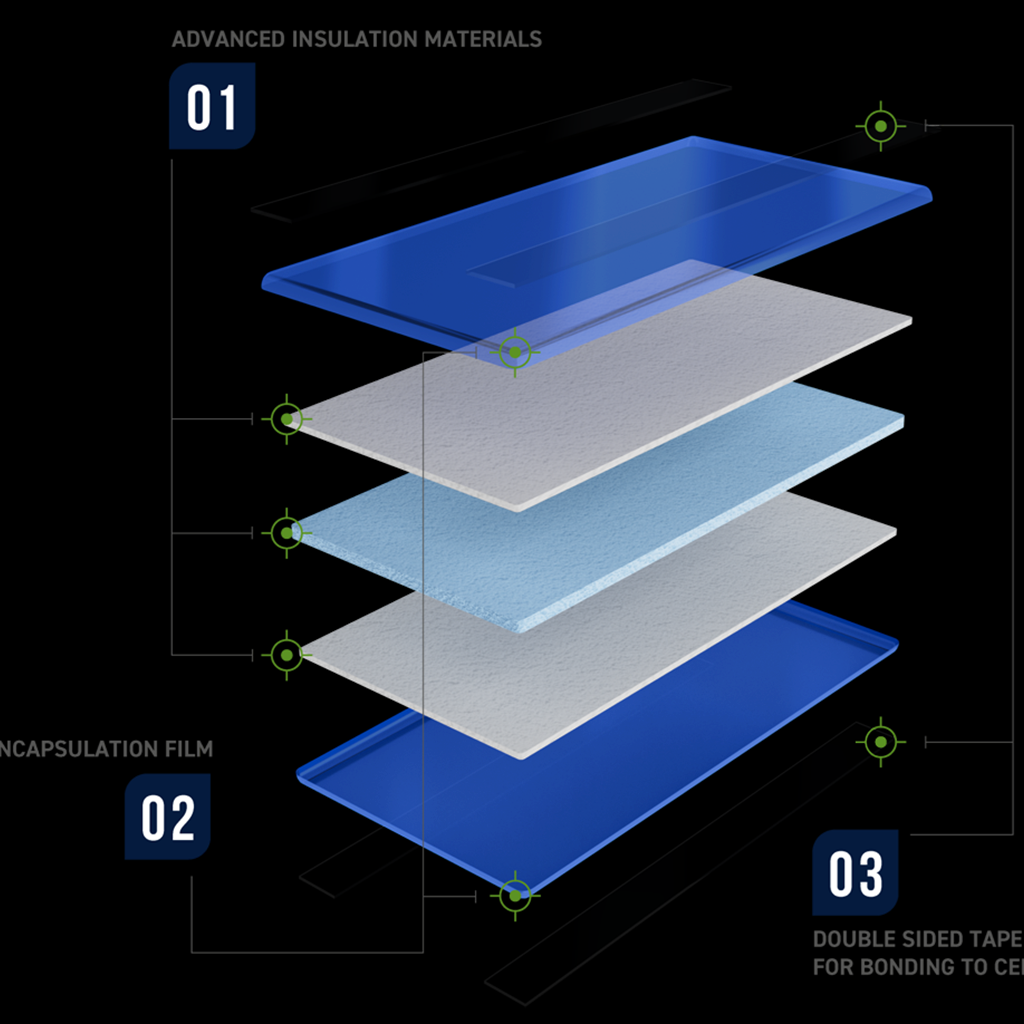

Advanced Insulation Materials1

Cooler bags use high-quality insulation materials like polyurethane foam, EVA foam, and reflective metalized polyester (Mylar). These materials reduce heat transfer and maintain low temperatures inside the bag for extended periods. Thick insulation increases thermal resistance, which is crucial for protecting perishable products such as vaccines and fresh food. Some modern cooler bags use multiple insulation layers. Each layer targets different heat transfer modes: conduction, convection, and radiation. For example, Mylar reflects radiant heat, while foam blocks conductive and convective heat flow.

Insulation Material Comparison

| Material | Key Feature | Typical Application |

|---|---|---|

| Polyurethane Foam | High R-value | Long-distance food shipping |

| EVA Foam | Lightweight | Small portable bags |

| Polyethylene Foam | Flexible | Reusable shopping cooler bags |

| Mylar | Reflective barrier | Medical cooler bags |

The choice of material affects how long a bag can keep items cold. Buyers should consider their product type, transport time, and external climate when selecting a bag.

Effective Sealing Mechanisms2

Cooler bags rely on airtight zippers and secure sealing closures to stop cold air from leaking and warm air from entering. This tight seal is essential to maintain the bag’s internal temperature. Even a small gap can lead to rapid temperature loss, which may spoil sensitive products. Some premium cooler bags have double zipper layers or magnetic seals for extra protection. Seals must be strong yet easy to open and close for users. In testing, bags with reinforced zippers showed better performance in keeping internal temperatures stable during long hauls.

Comparison of Sealing Mechanisms

| Type | Advantage | Limitation |

|---|---|---|

| Airtight Zipper | Strong seal | May wear out with heavy use |

| Velcro Closure | Easy to open | Less airtight |

| Magnetic Seal | Quick seal | Higher cost |

Buyers should regularly check seals for damage or wear to ensure consistent cold chain protection.

Use of Advanced Cooling Techniques3

Cooler bags improve cooling by using dry ice, gel packs, or phase change materials (PCMs). Dry ice keeps contents frozen for long periods but requires careful handling due to sublimation. Gel packs are flexible and conform to the shape of the goods. This maximizes contact and cooling efficiency. PCMs can maintain specific temperatures, such as 2–8°C, ideal for medical supplies. Some cooler bags include compartments for these aids, ensuring even temperature distribution.

Cooling Technique Comparison

| Method | Temperature Range | Duration | Safety Note |

|---|---|---|---|

| Dry Ice | -78°C | Long | Requires ventilation |

| Gel Packs | 0°C to 8°C | Medium | Safe and reusable |

| PCMs | Customizable | Long | Must match product needs |

Choosing the right technique depends on product sensitivity and trip duration.

Lightweight and Portable Design

Cooler bags are small and light compared to rigid coolers. This makes them easy to carry by hand or in vehicles with limited space. Their portability supports flexible delivery routes and quick hand-offs. In vaccine transport, portable cooler bags have proven effective at keeping doses within safe temperature limits, even when carried through remote areas without cold trucks. Lightweight designs reduce labor costs and make last-mile delivery more practical.

Portability Benefits

| Feature | Benefit |

|---|---|

| Compact Size | Fits tight spaces |

| Light Weight | Easy to carry |

| Flexible Shape | Adapts to different loads |

Buyers should balance size and insulation thickness for optimal convenience and performance.

Durability and Protection

Cooler bags protect against bumps, moisture, and punctures during transit. Outer layers often use tough fabrics like polyester or nylon, sometimes with water-resistant coatings. Inside, leak-proof linings prevent melted ice or condensation from escaping. Reinforced seams and sturdy handles add strength for repeated use. These features guard against contamination and physical damage, which is vital for high-value or medical products. Bags that withstand rough handling lower the risk of spoiled goods and costly returns.

Durability Features

| Feature | Purpose |

|---|---|

| Heavy-Duty Fabric | Tear and abrasion resistance |

| Waterproof Lining | Prevents leaks |

| Reinforced Handles | Secure carrying |

Regular cleaning and proper storage extend a cooler bag’s lifespan.

Pre-chilling and Use of Large Ice Blocks

Pre-chilling cooler bags before loading them reduces the initial cooling load on ice packs or gel packs. A cold bag absorbs less heat from the outside, so ice lasts longer. Using larger ice blocks instead of small cubes also slows melting because a larger block has a smaller surface area relative to its volume. This helps maintain a steady temperature for extended trips. Businesses shipping seafood or frozen desserts often rely on this method for better results.

Ice Block Strategy

| Ice Type | Melting Speed | Best Use |

|---|---|---|

| Large Block | Slow | Long shipments |

| Small Cubes | Fast | Short trips |

Pre-chilling is simple yet very effective. Users can place the empty bag in a freezer for several hours before packing.

Conclusion

Cooler bags increase cold chain efficiency through smart design, advanced insulation, tight sealing, portable construction, durability, and practical cooling strategies. These features help companies deliver fresh food, safe vaccines, and other sensitive products without loss of quality. In my experience, proper bag choice and good handling make a big difference in maintaining temperatures. Feel free to share your own tips or questions in the comments below!

-

Explore how advanced insulation materials enhance temperature control in cooler bags, ensuring product safety during transport. ↩

-

Learn about the importance of sealing mechanisms in cooler bags and how they prevent temperature loss, crucial for sensitive products. ↩

-

Discover various advanced cooling techniques that enhance the efficiency of cooler bags, ensuring optimal temperature for transported goods. ↩