Choosing the right printing method for cooler bags ensures your brand stands out with durability and visual appeal. This list explains the 10 best techniques, so you can match your logo needs to the perfect method.

7 Best Printing Techniques for Branding Cooler Bags

Cooler bag branding works best when the printing method matches the material, design complexity, and budget. This list covers durable, high-quality options for any style.

Explore each method and pick the best fit for your next custom cooler bag order.

Silk Screen Printing1

Silk screen printing is a classic and reliable choice for cooler bags. It pushes ink through a mesh stencil onto the fabric, creating bold, crisp designs. This method works best for solid colors and simple logos. It holds up well against daily use and washing. It performs especially well on polyester, cotton, and canvas cooler bags. For large runs with straightforward branding, silk screen printing is cost-effective and efficient.

Silk Screen Quick Facts

| Feature | Details |

|---|---|

| Best For | Solid logos, simple shapes |

| Materials | Polyester, cotton, canvas |

| Cost | Low for large quantities |

| Durability | High |

Heat Transfer Printing2

`

Heat transfer printing applies full-color images to bags using heat and pressure. It allows photo-quality artwork, gradients, and small text. A printed film is placed on the bag and then fused with heat. This method suits polyester and nonwoven bags well. It is perfect for complex logos and detailed promotional graphics. Small batches are cost-friendly, but large runs may cost more per unit than screen printing.

Heat Transfer Quick Facts

| Feature | Details |

|---|---|

| Best For | Detailed images, color gradients |

| Materials | Polyester, nonwoven |

| Cost | Medium |

| Durability | Good for detailed designs |

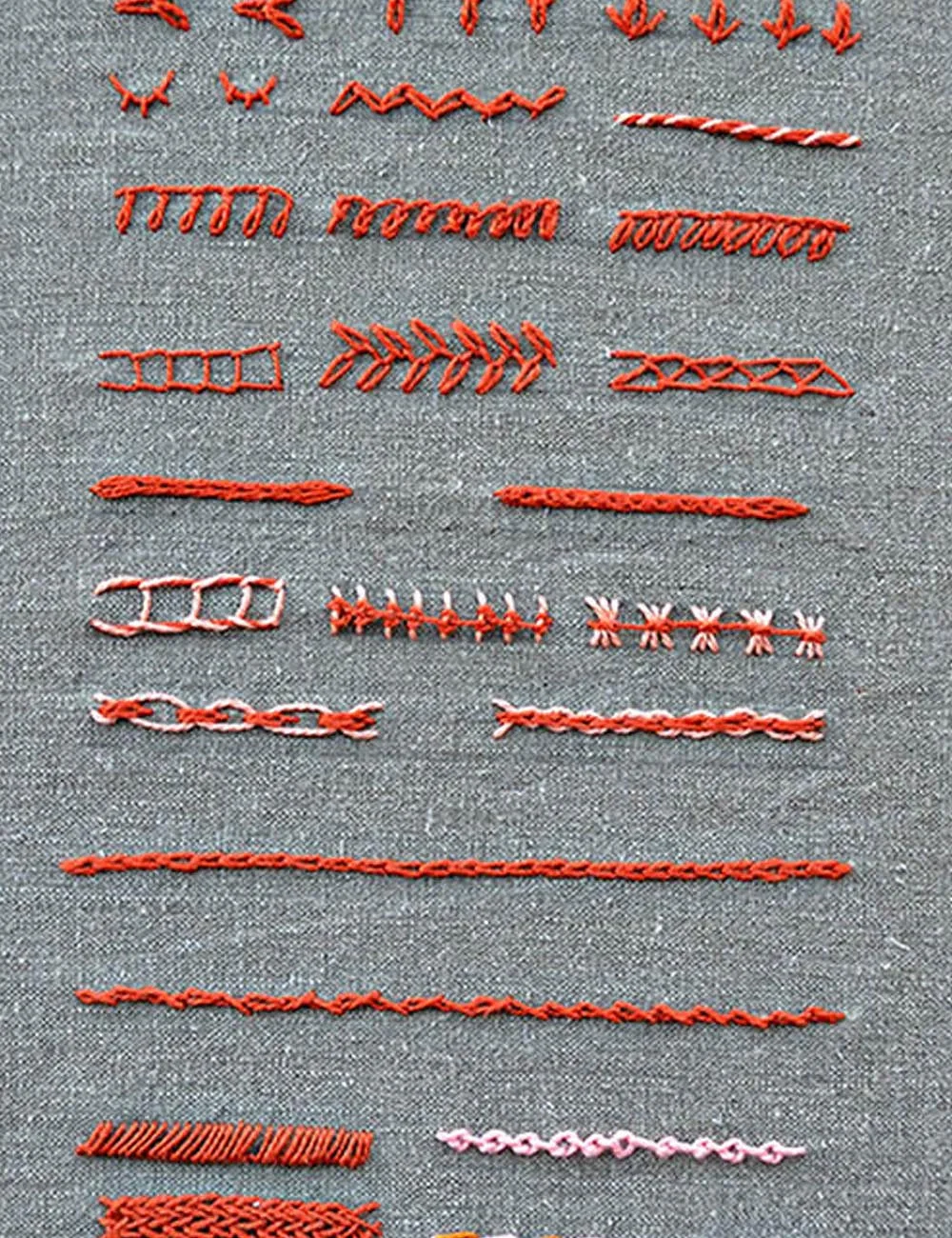

Embroidery

Embroidery stitches your logo with colored thread directly onto the cooler bag. It gives a rich, textured look that feels premium. Embroidery lasts long and resists fading. It works best for simple shapes and text due to stitching limits. It suits thicker fabrics like cotton canvas or padded panels. It adds an upscale touch for corporate gifts and high-end promotional items.

Embroidery Quick Facts

| Feature | Details |

|---|---|

| Best For | Simple logos, small areas |

| Materials | Canvas, thick polyester |

| Cost | Higher than printing |

| Durability | Excellent |

Digital Printing3 (Direct-to-Garment or Direct-to-Substrate)

Digital printing provides sharp, high-resolution results. It prints designs directly onto the cooler bag surface. This method handles multi-color, photo-like images easily. It works best on smooth synthetic materials. It is great for short runs or personalized orders with variable artwork. Digital printing keeps colors vivid and precise, making it a top choice for full-color branding.

Digital Printing Quick Facts

| Feature | Details |

|---|---|

| Best For | Detailed, multi-color images |

| Materials | Smooth synthetics |

| Cost | Medium to high for small runs |

| Durability | High |

Laminated Printing

Laminated printing seals your design under a clear protective layer. This adds shine and increases scratch resistance. The finish makes colors pop and protects the print from moisture. It is popular for nonwoven cooler bags used in promotions. Laminated bags look bright and attract attention at trade shows and giveaways. It is best for bold logos and simple graphics that need durability.

Laminated Printing Quick Facts

| Feature | Details |

|---|---|

| Best For | Bold colors, shiny effect |

| Materials | Nonwoven bags |

| Cost | Medium |

| Durability | Very good |

Direct to Film (DTF) Printing

DTF printing transfers ink from a special film to the cooler bag using heat and adhesive powder. It handles detailed graphics and works well on dark or light fabrics. DTF prints feel soft yet last long. It applies well to cotton, polyester, canvas, and blended synthetics. For multi-color logos with sharp lines, DTF is flexible and durable.

DTF Quick Facts

| Feature | Details |

|---|---|

| Best For | Intricate details, dark fabrics |

| Materials | Cotton, canvas, polyester |

| Cost | Medium |

| Durability | Excellent |

Flexographic Printing

Flexographic printing uses flexible rubber plates to apply ink. It is efficient for large orders with repeating designs. While not common for cooler bags, it works well for printing on outer packaging or bag labels. It can print multiple colors but is best for simple patterns. For high-volume runs with consistent artwork, it saves time and money.

Flexographic Quick Facts

| Feature | Details |

|---|---|

| Best For | High-volume, repeat designs |

| Materials | Packaging, labels |

| Cost | Low per unit at scale |

| Durability | Good for simpl |

-

Explore the advantages of Silk Screen Printing, a classic method that ensures bold designs and durability for your cooler bags. ↩

-

Learn about Heat Transfer Printing, perfect for detailed images and vibrant colors, making your cooler bags stand out. ↩

-

Discover Digital Printing, ideal for high-resolution, multi-color designs, ensuring your cooler bags look sharp and professional. ↩