Knowing what affects the price of wholesale cooler bags helps businesses control costs and get better value. This article explains seven key factors so you can make smarter bulk purchases.

7 Factors That Affect the Price of Wholesale Cooler Bags

The price of wholesale cooler bags depends on material quality, insulation type1, design features, customization, manufacturing methods, raw material prices, and market demand trends2.

Read on to understand each factor and make better choices for your next order.

Material Quality

The quality of the material is the first big factor. Stronger fabrics like thick polyester, high-grade nylon, or special neoprene cost more but last longer. They resist tearing and can hold heavy items without damage. Some fabrics have water-resistant or UV-protection coatings, which add cost. Cheaper fabrics feel thinner and may rip after short use. High-quality material also holds printed logos better and keeps its shape. When ordering, buyers should ask for fabric samples. A well-made cooler bag with premium fabric saves money in the long term because it does not wear out quickly.

Common Fabrics and Costs

| Fabric | Durability | Cost | Use |

|---|---|---|---|

| Thin Polyester | Low | Low | Budget giveaways |

| Thick Polyester | Medium | Medium | Retail bags |

| Nylon | High | High | Premium coolers |

| Neoprene | Very High | Very High | Specialty coolers |

Insulation and Lining

Insulation keeps food and drinks at the right temperature. Good insulation costs more to produce. High-density foam or thick thermal linings keep ice frozen for many hours. Some bags use multiple layers with foil or reflective liners. Heat-sealed or welded seams stop leaks, but they need special machines and skilled workers. Cheaper cooler bags use thin padding that does not hold temperature well and may leak over time. Buyers should check how many layers the bag has and if seams are stitched or sealed. Better insulation means better performance and longer customer satisfaction.

Insulation Types

| Insulation | Layers | Leak Proof | Cost |

|---|---|---|---|

| Single Foam | 1 | Low | Low |

| Multi-layer Foam | 2–3 | Medium | Medium |

| Closed-Cell Foam | 3+ | High | High |

Design Complexity and Features

A simple cooler bag with one pocket costs less than a complex design with many compartments, bottle holders, or special straps. Features like padded handles, reinforced corners, and waterproof linings increase production costs. Zippers, buckles, and adjustable straps need extra material and sewing time. Bags with foldable frames or hard inserts cost more to build. Buyers should think about their customers. Do they need a basic lunch cooler or a heavy-duty picnic cooler with many pockets? Paying for unnecessary features wastes money. Choosing the right design controls cost and meets real needs.

Common Features and Price Impact

| Feature | Adds Cost | Benefit |

|---|---|---|

| Extra Pockets | Medium | Better storage |

| Waterproof Lining | Medium | Stops leaks |

| Reinforced Straps | High | Safer carry |

| Hard Frame | High | Protects contents |

Customization and Branding

Adding your logo makes your cooler bag stand out, but it raises the cost. Simple one-color printing is cheap and fast. Multi-color prints, large prints, or full-surface designs cost more because they need extra setup time and special machines. Some companies use embroidery or rubber patches for a luxury look, which takes longer and costs more than basic printing. Custom shapes and sizes need new molds, which have upfront fees. Buyers planning big orders should ask suppliers about mold charges and bulk discounts to save money.

Branding Options

| Method | Cost | Best For |

|---|---|---|

| One-Color Print | Low | Budget promotions |

| Multi-Color Print | Medium | Retail bags |

| Embroidery | High | Premium gifts |

| Rubber Patch | High | Stylish branding |

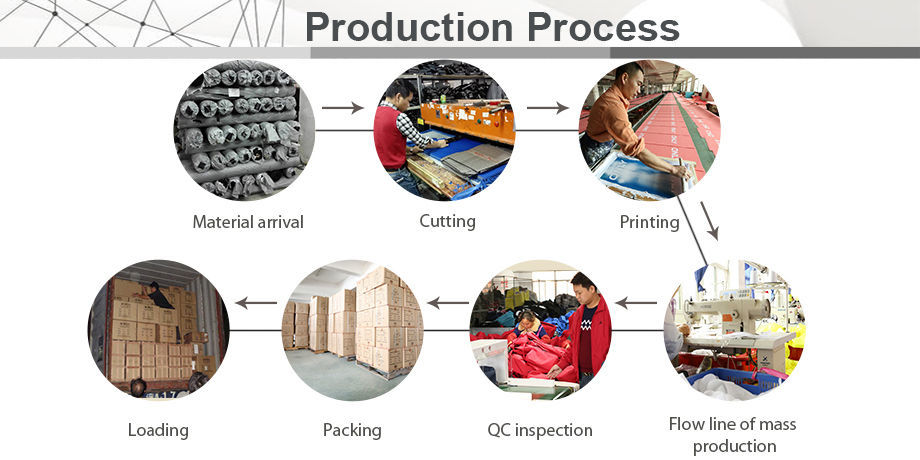

Manufacturing Process

The production method affects cost and quality. Large factories with modern machines can make thousands of bags quickly, lowering the unit cost. Bags made by hand or with special stitches cost more because they take longer. Some bags need special machines to weld seams for leak proofing. This process adds time and skill costs. Quality checks at each step also raise production costs but reduce the chance of defects. Buyers should ask how the supplier makes the bags and what machines they use. A good process means stable quality and fewer returns.

Production Types

| Process | Cost | Quality |

|---|---|---|

| Fully Automated | Low | Standard |

| Semi-Automated | Medium | Good |

| Handcrafted | High | Best |

Raw Material Cost Fluctuations

Material prices change with the global market. Polyester fabric prices can rise if oil prices go up. Foam and plastic parts also depend on oil costs. Zippers, buckles, and metal parts can get more expensive if there are supply chain problems. This makes bag prices change over time. Many factories update their prices every few months. Buyers should check market news and lock in prices early when planning large orders. Ordering ahead helps avoid sudden cost jumps and delays.

Example: Raw Material Changes

| Material | Risk Level | Impact |

|---|---|---|

| Polyester | Medium | Price changes every few months |

| Foam | High | Sensitive to oil costs |

| Zippers | Low | Stable but depends on metal cost |

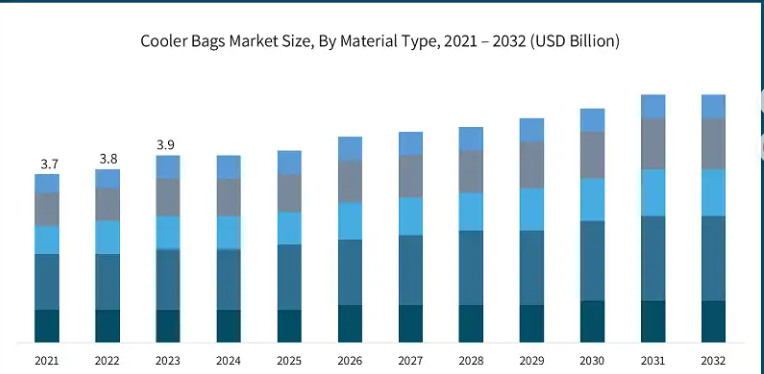

Market Demand and Trends

Trends change what customers want. Eco-friendly cooler bags use recycled materials that cost more but attract green buyers. Some brands want smart features like built-in thermometers or charging ports. These extras need more parts and new designs, raising the price. Demand also changes with the season. Cooler bag orders rise in summer and before holidays. High demand can push prices up. Buyers should follow trends and order early for big events. Understanding what is popular helps choose the right bag and avoid paying too much.

Trend Examples

| Trend | Cost | Benefit |

|---|---|---|

| Recycled Fabric | High | Good for green image |

| Smart Features | High | Unique selling point |

| Seasonal Prints | Medium | Limited edition sales |

Conclusion

The price of wholesale cooler bags depends on seven key factors. These are material quality3, insulation, design, customization, production, raw material costs, and market demand. At JiaRong Packing, we help clients find the best balance between cost and performance. In my experience, knowing these points saves time and money. Share your thoughts or questions below. Let’s discuss how to pick the best cooler bags for your business needs!

-

Insulation type is crucial for maintaining temperature. Learn more about how it impacts cooler bag efficiency and customer satisfaction. ↩

-

Staying updated on market demand trends can help you make informed purchasing decisions and avoid overpaying. Check this resource for the latest trends. ↩

-

Understanding material quality helps you choose durable cooler bags that save money in the long run. Explore this link for more insights. ↩