Have you ever wondered how paper shopping bags are made? Whether you use them for retail purposes or as gift bags, these items play an essential role in packaging. In this article, I’ll take you behind the scenes and explain the step-by-step process of making paper shopping bags.

Paper shopping bags are produced through a careful process involving material selection, printing, cutting, and assembly. Keep reading to discover how each step contributes to the final product.

Understanding how these bags are made will give you a better appreciation for their durability and eco-friendly properties. Let’s dive into the process of creating paper shopping bags.

How Are Paper Shopping Bags Made?

The process of making paper shopping bags involves several stages, from raw material selection to the final bag assembly. Each step is carefully performed to ensure the bags meet quality standards and are ready for use in retail.

Making paper shopping bags requires choosing the right materials, printing designs, cutting the paper, folding, and assembling them into bags. The final product is durable and ready for commercial use.

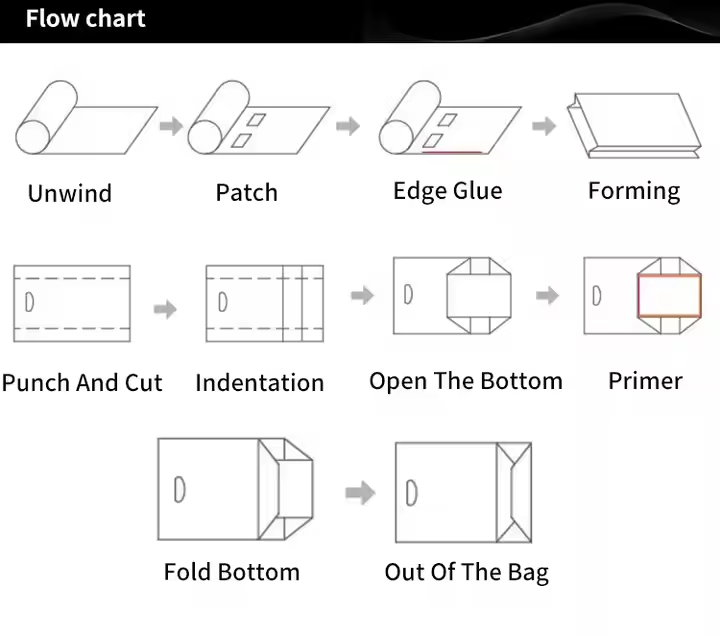

Step-by-Step Process of Making Paper Bags

- Material Selection: The first step involves choosing the right type of paper. Kraft paper is the most commonly used due to its durability and recyclability.

- Paper Cutting: The paper rolls are then cut into sheets according to the desired bag size.

- Printing: If the bags require custom logos or designs, the next step is printing. Modern printing techniques, such as flexographic printing, are used to ensure crisp, high-quality images.

- Bag Formation: The cut and printed sheets are folded and glued at the sides to form the bag shape. Handles are then attached, either with paper twists or cotton ropes.

- Assembly: The final step involves quality checks and assembling the bags. After the checks, the bags are packed for shipping.

Key Characteristics of a Paper Bag

Paper bags are often preferred over plastic due to their environmental benefits and versatile applications. But what makes a paper bag stand out? Let's break down some of the characteristics that make paper shopping bags a great option for businesses.

| Characteristic | Description |

|---|---|

| Material | Most paper bags are made from durable Kraft paper1. |

| Eco-friendly | Paper bags are recyclable and biodegradable.2 |

| Strength | Despite being lightweight, paper bags are strong enough to carry groceries, clothing, or gifts. |

| Customizability | Paper bags can be printed with logos or other designs, making them a great option for brand marketing. |

| Versatility | Paper bags come in various sizes and shapes, making them suitable for different purposes. |

How to Make Paper Bags Step by Step?

Making paper bags isn’t a complex process, but it requires precision and attention to detail. Here's a more detailed look at how paper shopping bags are made in the factory.

Making paper bags involves cutting, printing, folding, and assembling the paper into bags. Each step adds to the strength, durability, and appearance of the final product.

Step 1: Cutting the Paper Rolls

The paper used in making the bags typically comes in large rolls. These rolls are fed into a machine that cuts the paper into sheets. The size of these sheets depends on the final bag's dimensions.

Step 2: Printing the Designs

For retail or promotional purposes, bags are printed with logos, brand names, and other designs. High-quality flexographic printing ensures that the images appear sharp and vibrant on the paper.

Step 3: Folding and Gluing

After the printing, the paper sheets are folded into the shape of a bag. The sides are then glued, ensuring the bag is secure. Some bags might include a bottom gusset to make the bag wider, allowing it to hold more items.

Step 4: Attaching Handles

Handles are an important part of paper shopping bags. Paper twist handles are the most common, but cotton or plastic handles can also be added. These handles are glued to the top of the bag to ensure the bag can support the weight of the items inside.

Step 5: Final Assembly and Quality Check

After the handles are added, the bag is fully assembled. Quality checks are conducted to ensure that all bags are properly glued, the printing is correct, and there are no defects. Once approved, the bags are packed and ready to ship.

What Are the Characteristics of a Paper Bag?

Paper bags are not just practical, but they are also great for businesses looking to showcase their brand while promoting sustainability. What makes paper bags different from plastic bags?

Paper bags are more eco-friendly, customizable, and versatile than plastic bags. They offer a great balance between strength and sustainability.

Durability

One of the key characteristics of paper bags is their durability. While paper is generally lighter than plastic, kraft paper used in most paper bags is strong enough to carry heavy items, such as books or groceries.

Eco-friendliness

Unlike plastic bags, which contribute to long-term pollution, paper bags are recyclable and biodegradable, making them a better option for environmentally conscious businesses and consumers.

Customizability

Paper bags can easily be printed with custom logos or branding, making them an excellent marketing tool. Whether it’s for a store, a gift, or a promotional event, paper bags can help showcase a brand's identity.

What Is the Purpose of Making a Paper Bag?

The purpose of making paper bags extends beyond packaging. They serve various functions that benefit businesses, consumers, and the environment.

Paper bags are made for commercial use, eco-friendly packaging, and marketing. They provide a practical and sustainable way to carry items, while promoting brands through custom designs.

Packaging

The primary purpose of paper bags is to serve as packaging. Whether for groceries, clothing, or gifts, paper bags provide a strong, secure, and stylish3 way to transport items.

Marketing and Branding

Custom paper bags also serve as effective marketing tools. Retailers can use them to display their brand logos, slogans, or designs. A paper bag with a well-designed logo can enhance brand visibility4 and leave a lasting impression on consumers.

Sustainability

With growing environmental concerns, businesses are increasingly opting for paper bags over plastic bags5. Paper bags are biodegradable, recyclable, and renewable, making them an attractive option for companies focused on sustainability.

Conclusion

Understanding the process of how paper shopping bags are made gives you a deeper appreciation for their versatility and eco-friendly qualities. At Zhejiang JiaRong Packaging, we specialize in manufacturing custom paper bags for a variety of purposes, from retail packaging to promotional events. Visit our website JiaRong Packaging to explore our range of high-quality custom paper bags and learn how we can help elevate your business's packaging solutions.

-

Learn why Kraft paper is the preferred material for making paper bags. ↩

-

Understand the printing techniques used for high-quality paper bag designs. ↩

-

Learn why paper bags are a strong and secure packaging solution. ↩

-

Understand how paper bags can be a great marketing tool for businesses. ↩

-

Discover the environmental benefits of using paper bags over plastic alternatives. ↩