Understanding the 9 Buyer Personas Who Commonly Purchase PP Woven Bags

This article explores the key buyer personas for PP woven bags across industries. It establishes why these personas matter and how their unique needs shape purchasing decisions. As a packaging authority, our insights are grounded on real industry use cases and buyer behavior.

These nine buyer personas represent the typical industries and use cases for PP woven bags, highlighting their needs and priorities.

Keep reading to explore each persona in detail.

1. Agricultural Buyers1

These include farmers and agribusinesses. They use PP woven bags to store and transport seeds, grains, fertilizers, and animal feed.

They prefer breathable, strong, and reusable packaging. Their top needs include moisture resistance, UV protection, and proper sizing.

Dive deeper

Agricultural buyers need bags that protect contents from moisture, pests, and rough handling. They focus on breathability to prevent spoilage of grains and seeds. They require bags with high tear resistance to endure loading, transportation, and stacking.

Key factors they consider:

- Strength and durability: Must hold heavy loads without tearing.

- Breathability: Ensures airflow to prevent mold and moisture buildup.

- UV resistance: Protects contents in outdoor storage.

- Custom sizing: Tailored to specific seed or grain quantities.

- Printability: For labeling and branding on bags.

| Feature | Importance | Example Use Case |

|---|---|---|

| High-density weave | Critical for durability | Fertilizer sacks |

| Mesh ventilation | Prevent condensation | Grain storage |

| UV coating | Extends bag life outdoors | Seed transport in fields |

In real use, an agribusiness might order bulk bags to fit 50 kg rice or grain amounts. They often require logo printing, batch numbers, and expiration dates. Their ordering process prioritizes reliability and repeat orders.

2. Construction & Industrial Buyers2

Construction firms and industrial users rely on PP woven bags for heavy materials like cement, sand, chemicals, and aggregates.

They value strength, tear resistance, and compatibility with industrial handling standards.

Dive deeper

For construction and industrial buyers, bag failure is unacceptable. These bags carry abrasive and heavy materials. They must be puncture-proof and withstand rough loading. Buyers seek reinforced seams, dual-layer weaves, and resistance to chemicals.

Considerations include:

- Weight capacity: Bags must hold high-density materials safely.

- Abrasion and tear resistance: Handles rough crushed stone or sand.

- Chemical resistance: Important for materials like fertilizers or cement additives.

- Bulk sizing: Often large sacks for heavy loads.

- Compliance and labeling: Industry standard certifications or markings.

| Attribute | Application | Why It Matters |

|---|---|---|

| Reinforced seams | Cement transport | Prevents bag burst |

| Laminated coating | Chemical packaging | Protects material from moisture |

| High tensile strength | Heavy load durability | Ensures safety and logistics efficiency |

When procuring, these buyers often require sample testing. They specify load weights (e.g. 50 kg), color-coded bags for different materials, and printed information like safety instructions. Their orders are frequent and standardized.

3. Food Processing & Packaging Buyers

Food manufacturers and packaging firms use PP woven bags to package items such as flour, rice, sugar, and snack foods.

They emphasize food safety3, barrier properties, and print quality for branding and information display.

Dive deeper

These buyers must comply with food-grade standards. The bags require low moisture permeability, hygienic production, and print clarity for brand logos, nutritional info, and batch codes.

Their priorities:

- Food-safe material: Must meet regulatory standards.

- Moisture barrier: Keeps food fresh over transport.

- High-resolution printing: For clear branding and product details.

- Custom dimensions: Based on packaging weights (e.g. 10 kg flour)

- Bilingual or multilingual labels: For export markets.

| Feature | Required Standard | Buyer Benefit |

|---|---|---|

| Food-safe PP | FDA or local regulation compliant | Ensures safety |

| PE lining | Moisture barrier | Maintains freshness |

| High-res printing | Sharp labels and batch codes | Brand clarity and traceability |

Food buyers demand consistent print quality. They prefer anti-slip weaving to ease stacking in warehouses. They may order small runs with custom branding for limited product lines.

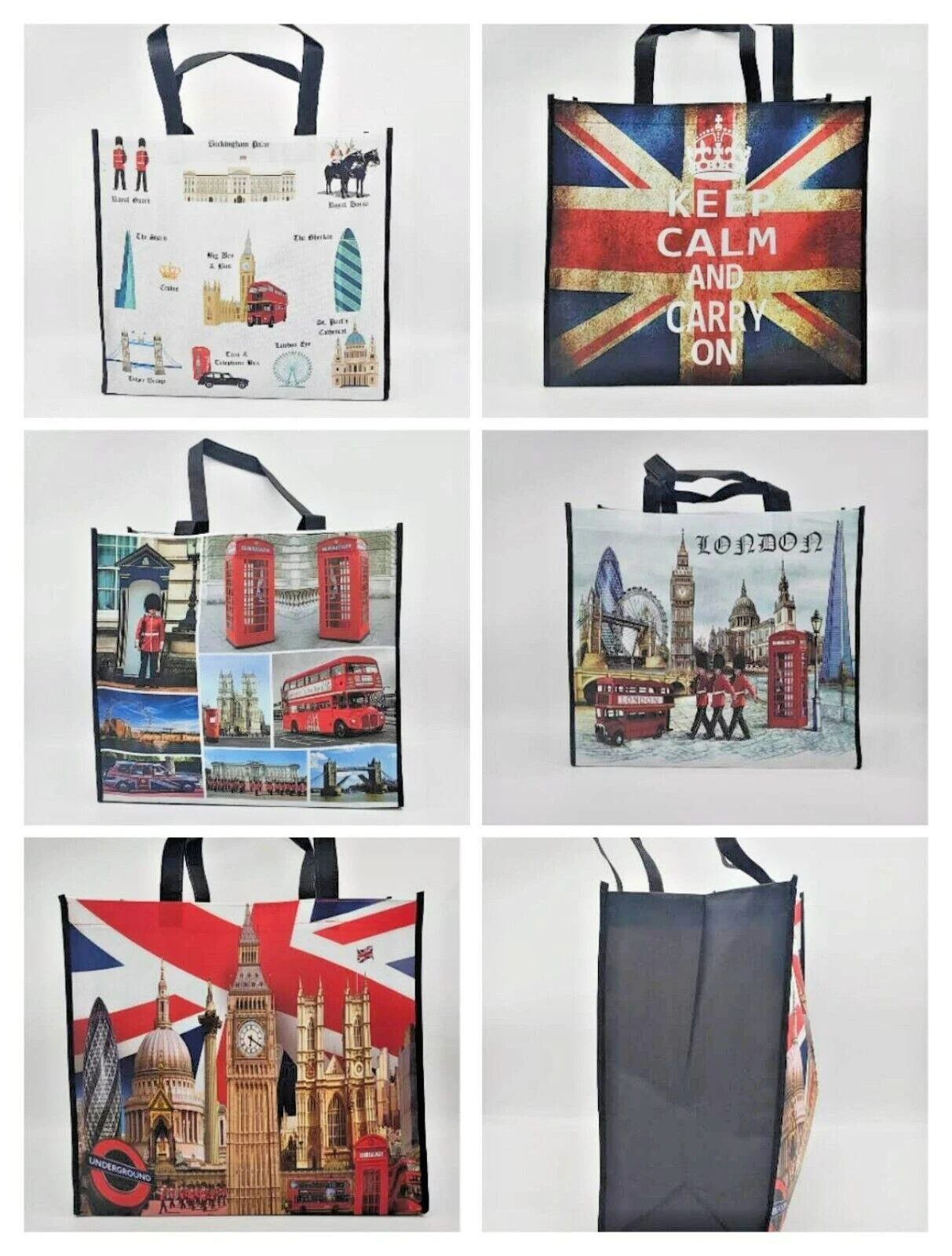

4. Retail & Grocery Buyers4

Supermarkets, grocery chains, and specialty stores use PP woven bags as shopping bags and for packaging bulky items.

They look for reusable, branding-friendly, and cost-effective options to align with sustainability goals.

Dive deeper

Retailers often need bags that customers reuse, offering long-term brand exposure. They require quality printing, comfortable handles, and eco-friendly materials. The bags must be strong yet lightweight and sometimes foldable for storage.

Buyer benefits include:

- Reusable design: Promotes sustainability and brand visibility.

- Custom print options: Bold graphics or logos.

- Lightweight & foldable: Easy storage at checkout.

- Cost-efficiency: Reusable wallets lower per-use cost.

- Compliance with plastic bans: Eco materials and certifications.

| Feature | Design Detail | Retail Benefit |

|---|---|---|

| Heavy-duty weave | Supports repeat use | Customer satisfaction |

| Reinforced handles | Secure hand-carry | Brand quality impression |

| Folded compact | Small storage footprint | Saves space |

Retail buyers often request sample orders with full-color bag design templates. They expect turn-key production from design to finished bag.

5. Exporters & Importers5

Companies involved in international trade rely on PP woven bags for shipping various goods. The bags’ lightweight and compliance-friendly design are major draws.

They assess weight limits, print regulations, shipping codes, and handling resilience.

Dive deeper

Exporters and importers need packaging that meets international shipping standards. Bags must be light to reduce shift weight costs. Print may need multiple languages or country codes. Durability protects goods over long shipping routes.

Key factors:

- Lightweight strength: Reduces shipping costs while staying secure.

- International compliance: Label languages, handling icons, barcodes.

- Stacking resilience: Withstands container pressure.

- Moisture and pest resistance: Protects goods from weather and insects.

- Custom sizes and logo printing: For various export product types.

| Attribute | Export Requirement | Business Benefit |

|---|---|---|

| ≤ 100 g/m² weight | Lower freight cost | Savings over large volume shipments |

| Multilingual print | Language compliance | Legal and customer clarity |

| Durable weaving | Long-distance protection | Reduces product damage |

They typically work with high-volume orders and need fast turnaround. Compliance with ISPM (wood packaging) or local laws can be required.

6. Promotional Product Buyers

Marketing firms, event organizers, or corporate clients order PP woven bags as branded giveaways.

They want vibrant print quality, lightweight bags that are memorable and cost-effective.

Dive deeper

Promotional buyers emphasize visual appeal and affordability. They want durable bags branded with logos, slogans, or event details. A colorful, reusable bag serves both as storage and a walking advertisement.

Buyer needs:

- Full-color printing: Logos or event graphics.

- Affordable bulk pricing: Often ordered in thousands.

- Medium weight: Durable yet light to hand out.

- Custom shapes or sizes: Tote style, drawstring, or shopper bag.

- Short lead time: For upcoming events or campaigns.

| Feature | Promotional Use | Buyer Advantage |

|---|---|---|

| High print quality | Brand exposure | Strong visual impact |

| Lightweight PP | Easy to carry for event attendees | Low shipping and handling cost |

| Foldable style | Changes to storage ease | Budget friendly logistics |

These buyers often re-order seasonally. They request mock-ups and print proofs before production starts.

7. Recycling & Waste Management Buyers

Waste collection firms and recycling centers use PP woven bags to gather recyclables and refuse.

Strength, capacity, and ruggedness are critical. The bags need to hold large volumes without tearing.

Dive deeper

These operations need heavy-duty bags to collect glass, plastics, or general waste. The bags must resist tearing under weight and rough handling. Handles and access are key. Some need printed icons or recycling messages.

Buyer considerations:

- High capacity: Able to hold large volumes.

- Strong weave: Handles heavy scrap or refuse.

- Easy to fill and carry: With handles or openings.

- Printed messaging: Recycling icons or instructions.

- Environmental compliance: Some may want recyclable PP.

| Feature | Operational Need | Practical Benefit |

|---|---|---|

| Reinforced handles | Manual lifting or machine use | Safety and durability |

| Thick woven PP | Carry heavy or sharp waste | Avoid tears or leaks |

| Printed instructions | Sorting or recycling guidance | Clear communication to users |

Buyers may specify color-coded bags for different recyclables. They often order on a recurring schedule.

8. Animal Feed Industry Buyers

Producers and distributors of animal feed rely on PP woven bags to package and transport feed for livestock and pets.

They emphasize protection from moisture, pests, and contamination, while handling heavy loads.

Dive deeper

Feed buyers need bags that preserve feed quality. Moisture and pest resistance are essential. The bags must be strong and often include liners to protect contents. Branding and labeling also matter.

Focus areas:

- Moisture barrier or lining: To keep feed dry.

- Pest-resistant mesh or coating: Prevent infestation.

- Heavy-duty weave: Able to support dense feed.

- Clear labeling: Feed type, weight, batch info.

- Stackable design: For warehouse efficiency.

| Component | Purpose | Benefit to Buyer |

|---|---|---|

| PE inner lining | Protects from moisture | Feed stays fresh and safe |

| UV-coating | For outdoor storage | Prevents material degradation |

| Bright print label | Feed and brand identification | Traceability and marketing |

These buyers order regularly and often require certification. They request sample bags for feed trials before large production runs.

9. Pharmaceutical & Chemical Industry Buyers

Clients in pharmaceutical and chemical sectors use PP woven bags to package and transport raw materials and finished products safely.

They require chemical resistance, clean production, and proper labeling or compliance marks.

Dive deeper

These buyers need highly controlled packaging environments. Bags must resist chemical exposure and meet hygiene standards. They use bags for powders, granules, or finished goods. Precise print and safety information are mandatory.

What they look for:

- Chemical-resistant PP weave or lining: To avoid contamination.

- Certified clean manufacturing: Meets pharma or chemical standards.

- Regulated labeling: Safety symbols, handling codes, batch numbers.

- Size accuracy: For precise dosage or weight.

- Sealable closures: Zipper or tie closures for airtight storage.

| Requirement | Industry Standard | Benefit |

|---|---|---|

| ISO-clean production | Pharma-grade hygiene | Safe for sensitive materials |

| Barrier liners | Chemical containment | Prevents leaks or reactions |

| Full compliance print | Hazard & batch codes | Legal and safety assurance |

Buyers typically require validation documents and frequent quality audits. Their orders may include small sample batches before l

-

Learn about the specific needs and preferences of agricultural buyers in the packaging industry. ↩

-

Gain insights into the specific requirements of construction and industrial sectors. ↩

-

Explore the essential food safety standards that packaging must meet. ↩

-

Discover the key factors that influence retail and grocery packaging decisions. ↩

-

Understand the unique packaging needs of exporters and importers. ↩