The handle design of a PP woven bag significantly influences its comfort, load capacity, and intended use. This article explores seven common handle types used in PP woven bags and how each serves different B2B and retail functions.

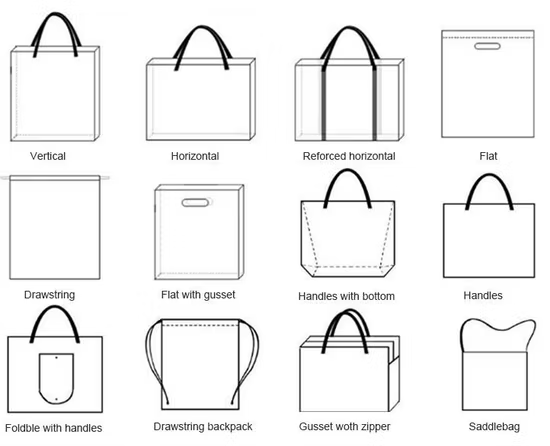

PP woven bags are fitted with a variety of handle types—from stitched straps to molded grips—each suited to specific weight, usage, and aesthetic requirements.

Choosing the right handle improves usability and extends the bag’s application across industries.

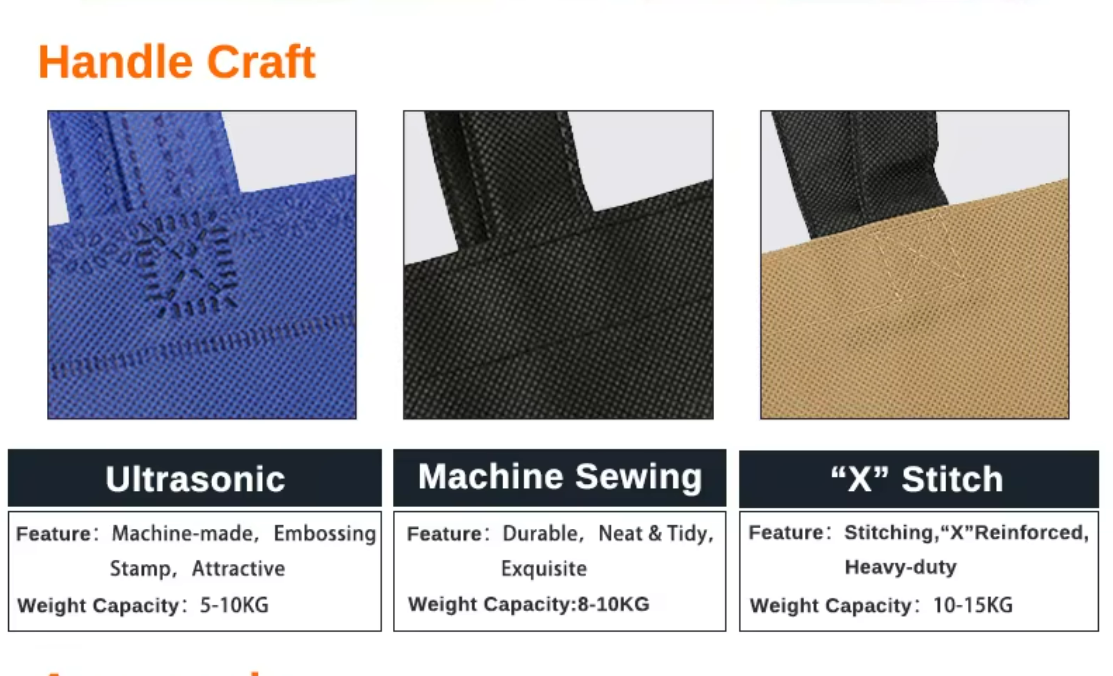

1. Top Stitched Handles[^1]

These flat woven straps are stitched along the top edges of the bag. They are durable and cost-effective, often used for multipurpose bags.

Use Case Benefits

| Industry | Application | Benefit |

|---|---|---|

| Retail | Grocery, shopping bags | Reliable and reusable |

| Promotional | Event giveaways | Custom printable |

| Apparel | Lightweight carry bags | Neat finish with flat profile |

This type is easy to mass-produce and supports a wide range of branding options.

2. Cross Stitched Handles[^2]

These are sewn with reinforced X-pattern stitching, which distributes stress more evenly and increases load capacity.

Use Case Benefits

| Industry | Application | Benefit |

|---|---|---|

| Industrial | Heavy goods, bulk packaging | Superior durability |

| Agricultural | Fertilizer and seed bags | Handles heavy, rough items |

| Transport | Freight-ready sacks | Prevents tear at joint points |

Cross stitching is often requested for safety-critical or bulk packaging solutions.

3. D-Cut Handles[^3]

These are die-cut directly into the top of the bag, offering a streamlined and economical handle design with no added materials.

Use Case Benefits

| Industry | Application | Benefit |

|---|---|---|

| Retail | Fashion stores, pop-up shops | Low cost, clean aesthetic |

| Events | Flyers and samples distribution | Easy to stack and carry |

| Takeout | Disposable food packaging | Fast, single-use carry |

This is a common handle for low-budget or temporary packaging needs.

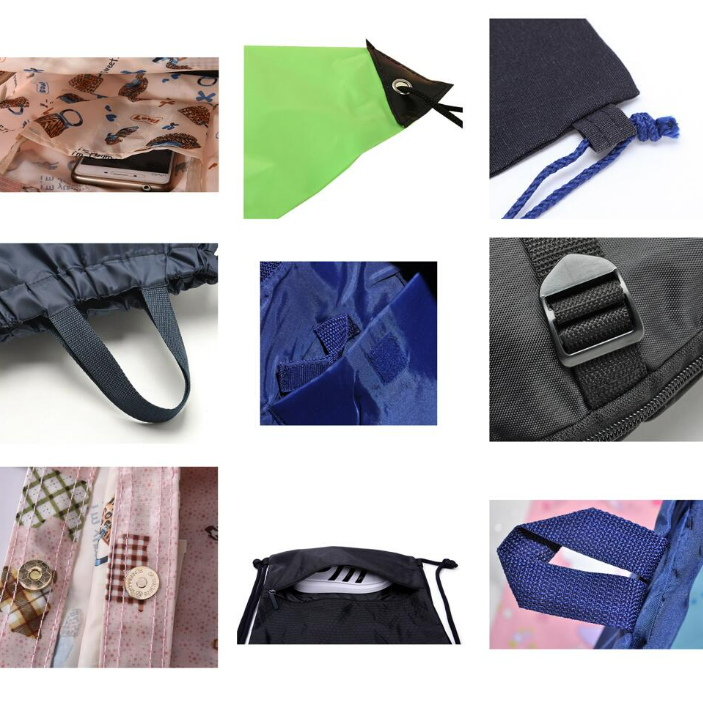

4. Narrow Woven Fabric (NWF) Handles[^4]

Made from dense woven tape, these handles match the bag material and offer a comfortable grip for frequent reuse.

Use Case Benefits

| Industry | Application | Benefit |

|---|---|---|

| Supermarkets | Reusable shopper bags | Soft, eco-friendly grip |

| Organic stores | Sustainable packaging | Fully recyclable materials |

| Eco Brands | Conscious consumer engagement | Long-lasting and washable |

These handles often accompany non-laminated or recycled-content bags.

5. Rope Handles[^5]

Braided or twisted rope handles are threaded through holes in the bag, then knotted or capped for secure holding.

Use Case Benefits

| Industry | Application | Benefit |

|---|---|---|

| Boutique Retail | Gift and luxury bags | Premium look and feel |

| Promotions | High-end branded merchandise | Stylish and versatile |

| Cosmetics | Sample kits and gift sets | Soft, upscale aesthetic |

Rope handles support high perceived value and are often combined with glossy finishes.

6. Plastic Injection-Molded Handles[^6]

These are rigid handles molded from plastic, affixed securely to the bag with rivets or integrated tabs.

Use Case Benefits

| Industry | Application | Benefit |

|---|---|---|

| Wholesale | Heavy grocery or hardware items | Ergonomic, fatigue-free use |

| Industrial | Repetitive-use packaging | Reduces strain and breakage |

| Pharmaceuticals | Supply chain totes | Sanitary and washable surface |

These handles enhance durability and comfort in repetitive-use settings.

7. Ultrasonic Welded Handles[^7]

Instead of being stitched, these handles are welded onto the bag using ultrasonic frequency, creating a smooth, clean seam without thread.

Use Case Benefits

| Industry | Application | Benefit |

|---|---|---|

| Food | Flour, sugar, rice packaging | Hygienic, thread-free seams |

| Medical Supplies | Sterile packaging applications | No contamination risk |

| Electronics | Cleanroom-compatible packaging | Dust-free and tamper-resistant |

Ultrasonic bonding is preferred where hygiene and product purity are critical.

Comparison Table

| Handle Type | Key Features | Typical Use Cases |

|---|---|---|

| Top Stitched | Flat, secure, general-use | Retail, totes, daily bags |

| Cross Stitched | Extra durability, reinforced | Industrial, heavy-duty |

| D-Cut | Integrated, cost-effective | Retail, events, giveaways |

| Narrow Woven Fabric (NWF) | Soft, durable, eco-friendly | Supermarkets, sustainability-focused |

| Rope | Decorative, premium appeal | Gift, boutique, promotional |

| Plastic Injection-Molded | Rigid, ergonomic, high load | Bulk shopping, specialty retail |

| Ultrasonic Welded | Seamless, hygienic, premium finish | Food, pharmaceutical, clean use |

Conclusion

Handle types are more than aesthetic choices—they define how a PP woven bag performs in specific industries and use cases. Whether you’re packaging food, branding luxury items, or distributing industrial materials, selecting the right handle improves user experience and bag lifespan.

At JiaRong Packaging, we offer all handle styles with full customization, supporting your exact application. Tell us which type you prefer or ask our team to help choose the best handle for your next bulk order.

---

[^1]: Discover the durability and cost-effectiveness of Top Stitched Handles for multipurpose bags.

[^2]: Find out how Cross Stitched Handles improve load capacity and durability for heavy goods.

[^3]: Understand the streamlined design of D-Cut Handles and their cost-effectiveness for retail.

[^4]: Explore the comfort and eco-friendliness of NWF Handles for reusable bags.

[^5]: Learn how Rope Handles add a premium look and feel to boutique and luxury bags.

[^6]: Discover the ergonomic benefits and durability of Plastic Injection-Molded Handles.

[^7]: Find out how Ultrasonic Welded Handles ensure hygiene and product purity in packaging.