Ordering canvas bags can significantly enhance your brand visibility, but even small mistakes can lead to quality issues, customer dissatisfaction, and financial loss. This article outlines the 10 most common errors businesses make when ordering canvas bags and provides practical advice to avoid them.

10 Mistakes to Avoid When Ordering Canvas Bags

Avoiding key mistakes in material, design, and logistics ensures your canvas bags meet expectations and maintain brand value.

Read on to understand how to make smarter choices that save money and improve your product quality.

Choosing Unsuitable Materials

Understand the differences in canvas weights and their impact on durability and cost.

Material Weight Matters

| Canvas Weight | Best Use Case | Pros | Cons |

|---|---|---|---|

| 6-8 oz | Promotional giveaways | Low cost, light | Wrinkles, low durability |

| 10-12 oz | Everyday shopping bags | Balanced durability & cost | May not suit heavy items |

| 14+ oz | Premium or heavy-duty use | High strength, premium feel | Higher cost, more rigid |

Using the wrong material type leads to complaints. Lightweight bags may appear wrinkled. Heavy canvas bags may be expensive and impractical. Choose based on the bag’s intended use and your customer’s expectations.

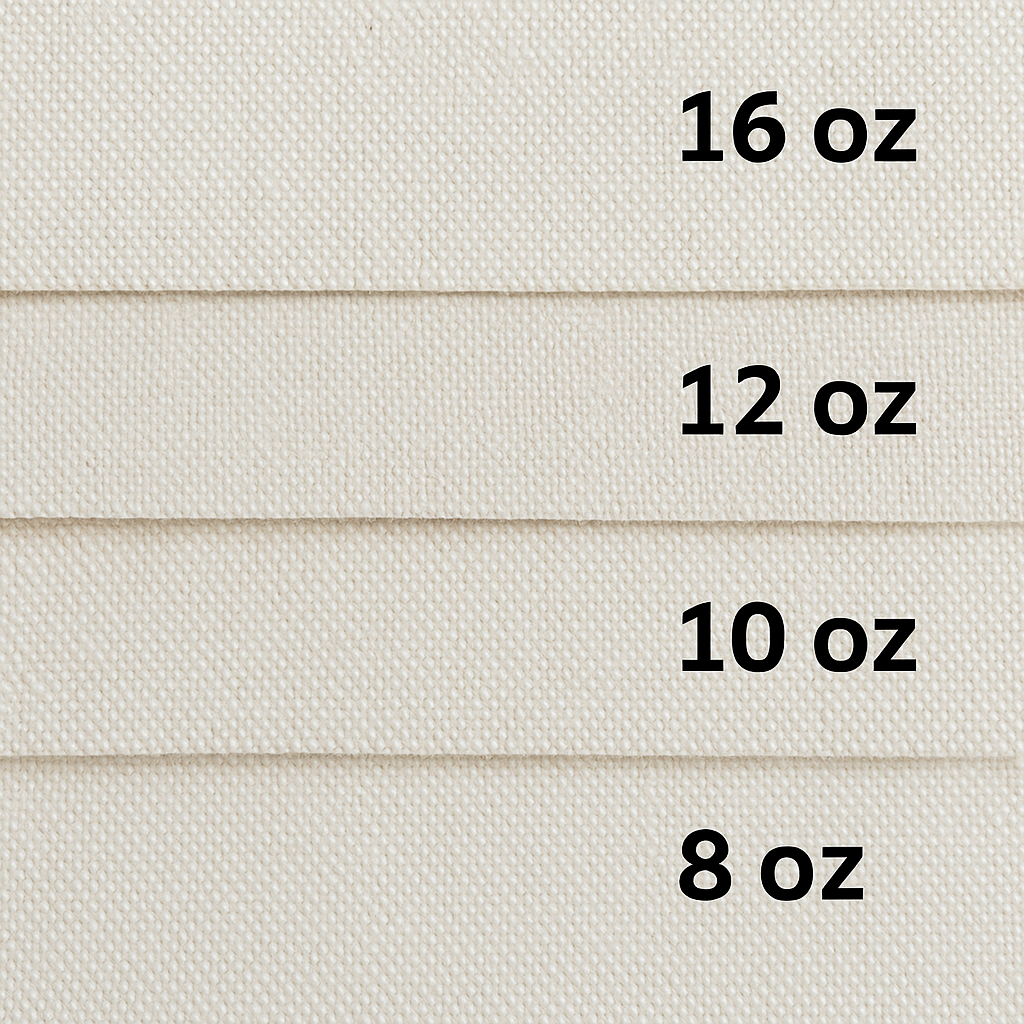

Ignoring Fabric Weight and Quality

Neglecting GSM ratings affects how a bag performs and feels.

Why GSM Ratings Are Critical

A canvas bag’s weight is measured in GSM (grams per square meter) or ounces. A low GSM canvas tears easily and fades after a few washes. High GSM fabric offers better printing surface and strength. Choose medium-weight canvas (around 10 oz or 340 GSM) for best results in most use cases.

Overlooking Bag Construction and Stitching

Check the stitching and handle strength to avoid quality issues.

Construction Details to Verify

| Feature | Why It Matters |

|---|---|

| Double-stitched seams | Prevents tearing under load |

| Reinforced handles | Essential for carrying weight |

| Flat seams | Helps printing and aesthetics |

Always request pre-production samples. Poor stitching or handle detachment damages your brand reputation. Reinforced seams and strong stitching extend the bag’s lifespan and ensure customer satisfaction.

Misjudging Printable Area and Design Placement

Poor design placement can ruin otherwise good bags.

Consider Bag Layout in Design

Many clients forget that handles, seams, and gussets affect print space. A design that looks great on screen might get cut off or misaligned in production. Ask your supplier for precise print templates and mock-ups to visualize the final look.

Rushing the Ordering Process Without Planning Ahead

Time constraints lead to bad decisions and costly compromises.

Plan for Production and Shipping Timelines

| Process | Estimated Time |

|---|---|

| Production | 7–15 business days |

| Air Shipping | 5–7 days |

| Sea Shipping | 20–45 days |

Avoid last-minute orders. Delays are common during peak seasons. Always allow buffer time for sampling, approval, and production.

Poor Branding Communication

Inaccurate branding can lead to rejected orders and financial loss.

Provide Clear Brand Instructions

| Branding Element | How to Communicate |

|---|---|

| Logo | Vector file (AI, PDF, EPS) |

| Colors | Pantone or CMYK codes |

| Fonts | Include font files or names |

Give detailed brand guidelines. Review and approve samples before bulk production. Miscommunication results in inaccurate colors, fonts, and layout issues.

Focusing Solely on Price Over Supplier Reliability

Low-cost suppliers may not guarantee quality or delivery.

Evaluate Suppliers Beyond Price

Choose suppliers with established records, positive reviews, and strong production capacity. Ask for factory certifications and logistics support. A reliable partner ensures timely deliveries and consistent quality, saving costs long-term.

Not Offering Enough Variety in Styles and Materials

A limited catalog restricts your potential sales.

Expand Your Product Range

Offer diverse options like:

| Bag Type | Best Use Case |

|---|---|

| Organic cotton bag | Eco-conscious promotions |

| Jute tote | Rustic or natural branding |

| Canvas pouch | Cosmetic or travel kits |

More variety increases your appeal to different buyer segments and boosts repeat orders.

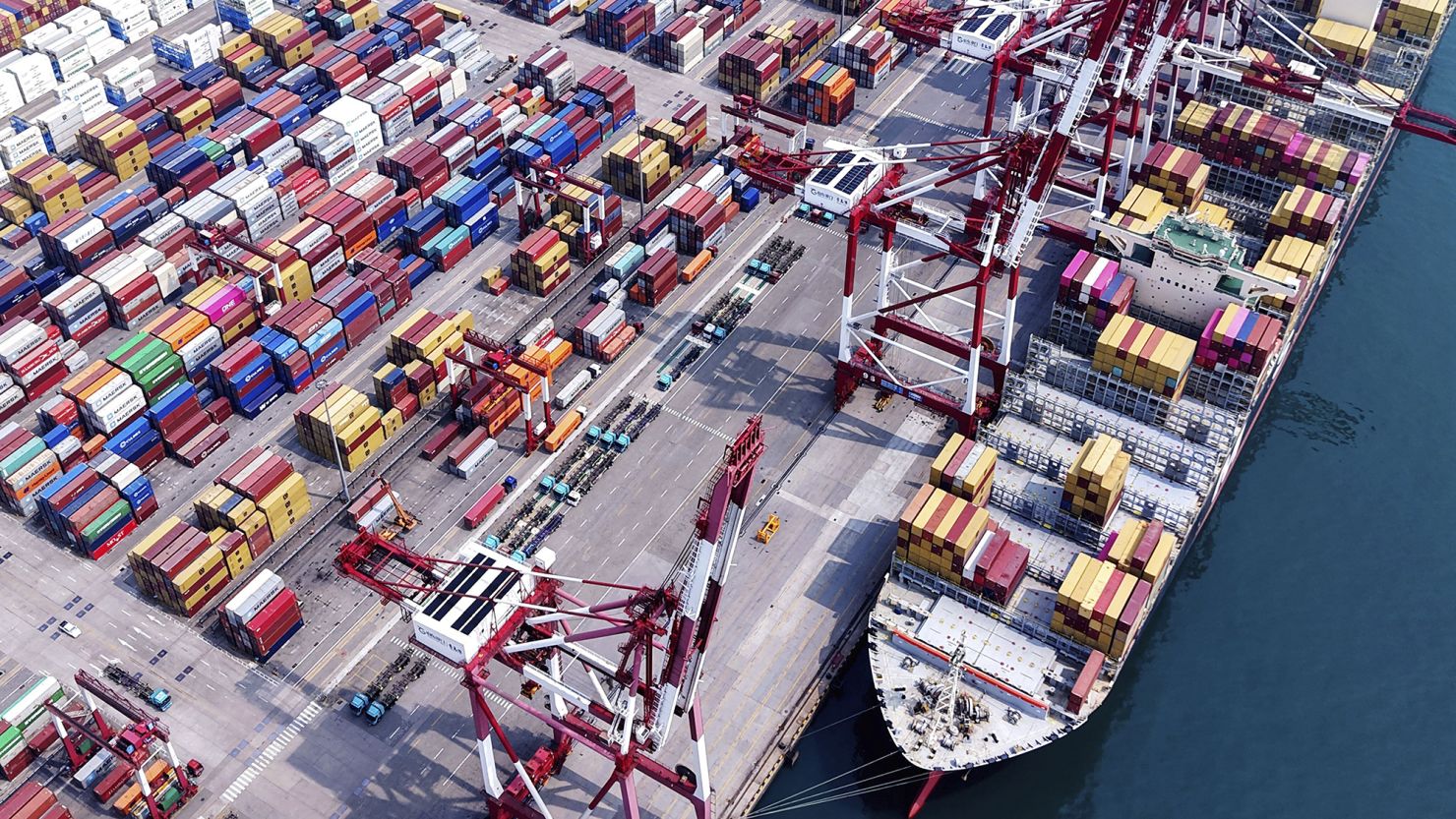

Underestimating Shipping and Storage Costs

Large canvas bags take up space and can raise costs.

Optimize Storage and Shipping

| Factor | Tip |

|---|---|

| Volume weight | Use vacuum packaging if possible |

| Storage space | Plan shelf dimensions and layout |

| Supplier support | Use regional warehouses to save cost |

Shipping large volumes without considering space and weight leads to unexpected expenses. Choose suppliers with logistics expertise and consider consolidation.

Skipping Quality Checks and Sample Testing

Final product inspection prevents surprises and returns.

Verify Before You Commit

| Item to Check | Reason |

|---|---|

| Stitch strength | Confirms durability |

| Print alignment | Ensures brand consistency |

| Handle material | Avoids snapping or stretching |

Always inspect samples for material quality, printing precision, and construction. Avoid skipping this step, even for repeat orders. It safeguards your brand image and reduces the risk of customer complaints.

Conclusion

Avoiding these 10 mistakes can make a big difference in the success of your canvas bag orders. Take the time to choose the right materials, verify designs, and work with trustworthy suppliers. In our experience at JiaRong Packing, proactive planning and communication have helped clients reduce returns and boost customer loyalty.

We welcome your thoughts—share your own tips or mistakes to avoid in the comments below.