PP woven bags are among the most versatile packaging solutions today. Their strength, cost-efficiency, and customizability make them valuable across many sectors. This article explores 10 industry applications backed by real use cases, showing how they solve packaging, transport, and storage problems efficiently.

PP woven bags are used in agriculture, construction, retail, logistics, and more due to their durability, breathability, and customizability.

Discover how each sector leverages these high-performance bags to meet specific operational needs.

Agriculture

Dive Deeper

PP woven bags are essential in modern farming. They store grains, seeds, fertilizers, and fresh produce. The material is breathable, preventing mold in humid storage. These bags are light, making them easy to transport. Farmers value their tear-resistance[^1] when loading or unloading.

Common Features

- Breathable: Reduces moisture and spoilage

- UV resistant[^2]: Protects seeds and grains in sunlight

- Strong seams: Withstand stacking and rough handling

| Item Stored | Purpose | Bag Type |

|---|---|---|

| Rice, wheat | Dry storage, shipping | Laminated woven sack |

| Fertilizer | Bulk transport | BOPP laminated bag |

| Vegetables | Breathable packaging | Vented woven sack |

These bags improve shelf life and reduce waste in the farming supply chain.

Food Industry

Dive Deeper

Food-grade PP woven bags are used to pack maize, flour, pulses, and sugar. They meet hygiene standards and often include liners. This prevents contamination. They resist punctures and maintain shape under pressure, which is critical in transport.

Application Advantages

- Food-safe coating or liner

- Custom printed branding

- Easy to handle in bulk

| Food Item | Safety Feature | Packaging Method |

|---|---|---|

| Flour | Food-grade liner | Heat-sealed woven bag |

| Sugar | Moisture protection | Multi-layered sack |

| Pulses/beans | Custom print & venting | Breathable woven sack |

These bags ensure cleanliness, efficiency, and visibility on store shelves.

Construction and Building Materials

Dive Deeper

Construction sites use PP woven bags for cement, sand, bricks, and mortar. Their high tensile strength helps carry heavy contents. They also resist UV rays, a feature needed for open-air storage. Their tough exterior handles sharp and abrasive materials.

Industry Needs

- High load capacity

- UV stabilization

- Dust prevention

| Material Carried | Needed Feature | Bag Variant |

|---|---|---|

| Cement | Tear resistance | BOPP woven bag |

| Sand | Bulk transport | Unlaminated sack |

| Roofing tiles | Moisture protection | Laminated woven sack |

These bags help builders avoid material loss during tough handling and transport.

Logistics and Shipping

Dive Deeper

PP woven bags[^3] are used to ship documents, small parts, and bulk goods. Variants include zipper courier bags and flexible intermediate bulk containers (FIBCs). They reduce damage and help organize storage and shipping. Printed versions support barcoding and inventory control.

Practical Benefits

- High-volume shipping

- Multiple closure types

- Label-ready surface

| Item Type | Suitable Bag | Feature |

|---|---|---|

| Electronics | Inner liner bag | Moisture barrier |

| Courier parcels | Zipper woven bag | Reusable and secure |

| Warehouse parts | FIBC | Forklift-compatible |

Logistics operations use these bags for efficient, protective transport.

Waste Management and Recycling

Dive Deeper

Recyclers use PP woven bags for sorting metals, e-waste, and paper. These bags hold sharp, bulky, or irregular contents. Their durability prevents tears. Color-coded options help with sorting. They are washable and reusable[^4], ideal for cities or industrial waste collection.

Key Features

- Tear resistance

- Color-coded options

- Handles or loops for lifting

| Waste Type | Best Bag Feature | Use Case |

|---|---|---|

| Construction debris | Bulk resistance | Demolition cleanup |

| Paper/glass | Sorting support | Municipal recycling |

| E-waste | Leak-proof & heavy-duty | Electronics disposal |

Recycling operations depend on these bags to cut costs and improve sorting efficiency.

Retail and Packaging

Dive Deeper

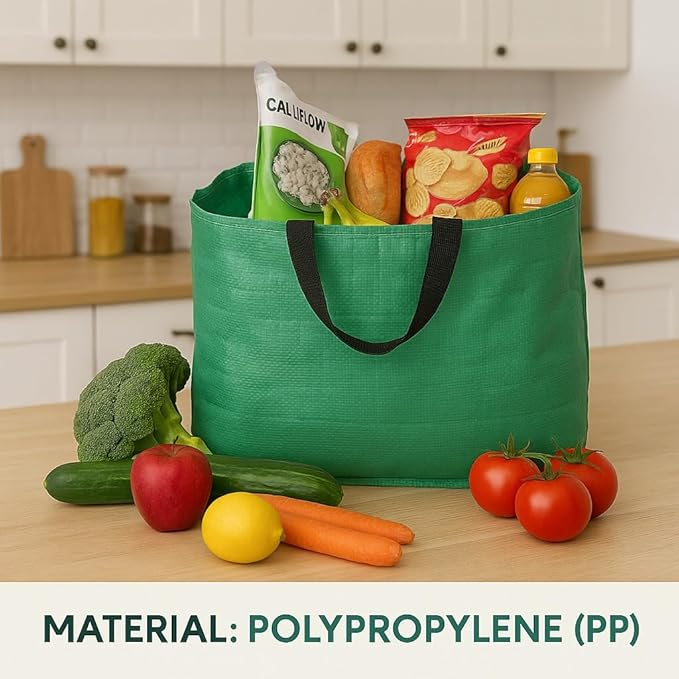

Retailers use PP woven bags for clothes, consumer goods, and promotional giveaways[^5]. These bags come in many styles and can be printed with logos. They are reusable and reflect brand quality. Some are laminated for water resistance, making them ideal shopping bags.

Retail Uses

- Logo printing for marketing

- Durable and reusable

- Many size and shape options

| Retail Use | Branding Option | Example |

|---|---|---|

| Boutique clothing | Glossy lamination | Gift-style carry bags |

| Supermarkets | Bulk design + printing | Shopping bags |

| Trade shows | Promotional branding | Giveaways with logos |

These bags offer both function and style for product and brand presentation.

Polymer Industry

Dive Deeper

Plastic resin manufacturers use PP woven bags to pack pellets and powders. They support clean bulk transport[^6] and prevent material loss. These bags can be antistatic or UV treated, depending on polymer sensitivity. They also simplify handling in manufacturing plants.

Industry Considerations

- Dust containment

- Custom print for material traceability

- Chemical-resistant coatings

| Material Type | Required Protection | Bag Type |

|---|---|---|

| Polymer pellets | Dust control | Sealed woven sack |

| Composite fibers | UV resistant | Laminated woven bag |

| Plastic powders | Antistatic lining | Coated woven sack |

Polymer factories benefit from accurate labeling, containment, and safe handling.

Tourism and Transport

Dive Deeper

PP woven fabric is used to produce travel sacks, tents, and covers. Lightweight yet strong, these bags support tourists and construction crews. Their weatherproof coatings[^7] protect equipment. Roll-up styles and printed surfaces add functionality and aesthetics.

Common Applications

- Protective trip sacks

- Equipment and gear covers

- Tents and screens

| Use Case | Required Feature | Type |

|---|---|---|

| Camping sacks | Water-resistant fabric | Laminated woven bag |

| Sunshade covers | UV and heat resistant | BOPP woven fabric |

| Temporary walls | Lightweight + strong | Roll-up tarp style |

Tour operators and contractors value these for fast, durable setup in outdoor conditions.

Mining and Infrastructure

Dive Deeper

PP woven bags carry sand, gravel, and geotextile materials in mines and on large job sites. Their bulk-handling capability simplifies road, rail, and port construction. Some are UV-treated for extended outdoor use. FIBCs are often used for storage and lifting.

Worksite Needs

- Bulk capacity

- Sun and weather resistance

- Forklift and crane compatibility

| Application | Benefit | Bag Feature |

|---|---|---|

| Sandbagging | Stability for roads | UV-resistant woven bag |

| Gravel storage | Long-term exposure | Ventilated woven sack |

| Port loading | High load capacity | FIBC |

These bags support critical infrastructure by increasing safety and transport efficiency.

Humanitarian and Emergency Aid

Dive Deeper

NGOs use PP woven bags to deliver food, medicine, and shelter materials. These bags are strong enough to carry supplies over long distances. Their low cost and volume handling are ideal for crisis zones. Labels can be printed in many languages.

Emergency Use

- Large volume capacity

- Weatherproof and stackable

- Multi-language labeling

| Relief Item | Bag Function | Preferred Type |

|---|---|---|

| Rice/grains | Food-safe, moisture-proof | Laminated woven sack |

| Clothing kits | Compact & durable | Foldable woven bag |

| Medical supplies | Labeled, sealed options | Zipper-top courier bag |

They are a vital resource for fast, secure aid in disaster zones.

Conclusion

PP woven bags adapt to the needs of many industries—from farming and retail to disaster relief. Their customizable design, strength, and breathability make them a preferred packaging solution. Whether you're shipping cement, selling clothing, or distributing food, there is a PP woven bag fit for your job.

From our experience at JiaRong Packing, tailoring these bags to customer requirements (like UV resistance or waterproof lamination) can significantly improve logistics and branding. Share your sector needs in the comments—we’re happy to help you choose the right solution.

---

[^1]: Find out how tear-resistance contributes to the durability of these bags.

[^2]: Learn about the importance of UV protection for materials exposed to sunlight.

[^3]: Explore the versatility and advantages of PP woven bags across different sectors.

[^4]: Learn how reusability contributes to sustainability and cost savings.

[^5]: Explore how branded bags can enhance marketing efforts.

[^6]: Discover how bulk transport solutions can streamline logistics.

[^7]: Discover how weatherproofing enhances the durability of outdoor products.