When it comes to purchasing bulk custom bags for your business, there are several factors you need to consider. From evaluating quality to negotiating the best price, each step plays a crucial role in ensuring you get the best deal for your investment. But how do you assess quality and pricing effectively? In this article, I’ll walk you through the key steps to take when buying bulk custom bags, so you can make informed decisions.

Buying bulk custom bags requires a careful balance between assessing quality and comparing prices. Let’s explore how you can evaluate both effectively before placing an order.

Making the right decision on bulk custom bags is essential for your business. Let's dive into how you can evaluate the quality and compare prices to ensure you're getting the best deal.

How to Assess the Quality of Custom Bags Before Placing a Bulk Order

Assessing the quality of custom bags is essential before committing to a bulk order. You need to ensure that the materials, construction, and overall design meet your standards. Here’s how you can evaluate the quality:

To assess the quality of custom bags, check materials, stitching, durability, and sample quality. Don’t forget to inquire about production standards.

Inspect Material and Durability

Start by evaluating the fabric used for the custom bags. Materials like non-woven fabric1, canvas, or polyester are commonly used in custom bags, but it’s essential to assess their quality. Is the fabric strong enough to withstand daily use? Does it feel premium or flimsy? Make sure the material is suitable for the intended purpose of the bags.

Stitching and Construction

Check the stitching and overall construction of the bags. Poor stitching can lead to fraying and tears over time. Look for bags with reinforced seams and strong stitching, especially around high-stress areas like handles and zippers.

Request Samples

Always request samples before placing a large order. This gives you a first-hand look at the bag’s quality and allows you to test its durability. Some suppliers may offer free samples, while others might charge a small fee. In either case, it’s worth the investment to ensure the bags meet your expectations.

What Factors Affect the Pricing of Bulk Custom Bags and How to Compare Quotes

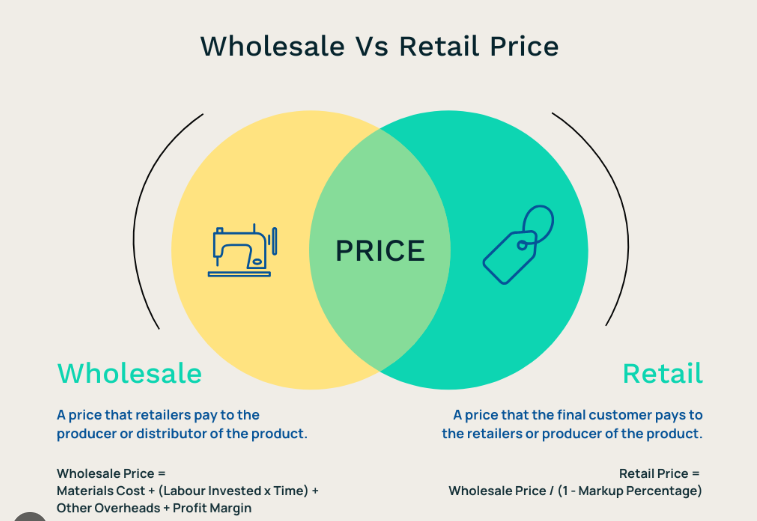

Understanding what affects the pricing of bulk custom bags will help you compare quotes more effectively and find the best value for your business. Several key factors influence pricing:

Pricing for bulk custom bags2 is influenced by factors like material choice, order volume, design complexity, and supplier location.

Material and Design Complexity

The type of material you choose plays a significant role in the pricing of the custom bags. High-end materials such as leather or eco-friendly fabrics will cost more than basic polyester or non-woven fabric. Additionally, the complexity of your design—such as custom logos, multiple colors, or special features—will increase the cost.

Order Volume

Generally, the larger the quantity you order, the lower the price per unit. Bulk orders allow suppliers to produce large batches, which reduces the overall production cost. However, smaller orders might come with higher unit costs, as suppliers need to account for production setup and other overhead expenses.

| Factor | Impact on Pricing |

|---|---|

| Material | Higher-end materials raise the price |

| Design Complexity | More colors or special features increase the cost |

| Order Volume | Larger orders reduce per-unit pricing |

Supplier Location and Shipping Costs

The supplier’s location and shipping fees3 are also important to consider when comparing quotes. Suppliers in regions with lower labor costs, such as China or Vietnam, may offer cheaper pricing compared to those based in Europe or North America. However, shipping costs may increase for overseas suppliers, so always factor this into the total cost.

Why Quality Control is Crucial When Purchasing Bulk Custom Bags for Your Business

Quality control (QC) is essential when purchasing bulk custom bags to ensure consistency and high standards across the entire order. Without effective quality control, you risk receiving bags that don’t meet your expectations or even fail in critical ways.

Quality control ensures that each custom bag meets the required standards, reducing the risk of defective or subpar products reaching your customers.

The Role of QC in Bulk Orders

When ordering custom bags in bulk, it’s vital that the bags are produced consistently and meet the desired specifications. Quality control helps identify defects in production early, saving you time and money by preventing defective bags from reaching your customers. Make sure the supplier has a robust QC process in place, especially for large orders.

Third-Party Inspections

If you are working with a supplier overseas, consider using a third-party inspection service to check the quality of the bags before shipment. These services conduct on-site inspections and provide detailed reports on the quality, ensuring that the bags match your requirements.

Consistency in Production

Quality control also ensures that all the bags in your bulk order are consistent in terms of color, material, and design. This is particularly important if you’re ordering bags to be used for branding purposes, as inconsistency can harm your business’s image.

How to Negotiate Pricing with Suppliers for Bulk Custom Bags Without Compromising Quality?

Negotiating pricing with suppliers is a delicate balancing act. You want to secure the best deal while ensuring the quality of the custom bags doesn’t suffer. Here are a few tips for negotiating without compromising on quality:

Negotiating with suppliers requires finding a balance between cost savings and maintaining high quality. Here’s how to approach it effectively. negotiating with suppliers4, bulk purchase discounts5, quality control6

Be Transparent About Your Budget

Be upfront with the supplier about your budget for the bulk order. If your budget is tight, the supplier may suggest alternative materials or designs that can lower costs without sacrificing quality. Clear communication about your budget allows the supplier to propose the most cost-effective options.

Request Discounts for Larger Orders

Suppliers often offer discounts for bulk purchases, so don’t be afraid to negotiate for a lower price per unit when placing a large order. Ask about tiered pricing, where the price decreases with the quantity you order.

Don’t Compromise on Quality for a Low Price

It can be tempting to push for a low price, but remember that compromising on quality can harm your business in the long run. Instead of focusing solely on the lowest price, focus on getting the best value for the price. A slightly higher price might be worth it if it guarantees better quality bags that will last longer and reflect well on your brand.

Conclusion

Evaluating the quality and pricing of bulk custom bags involves understanding several key factors, from the materials and design to supplier reliability and quality control. By carefully assessing these elements and negotiating wisely, you can ensure that you make a smart purchase for your business. At JiaRong Packing, we offer a variety of customizable bags that meet high standards of quality at competitive prices. Check out our products https://zjjrpackaging.com/ and get in touch with us for more details.

-

Discover the advantages of non-woven fabric in custom bags and its durability. ↩

-

Discover how ordering in bulk can lower the per-unit price of custom bags. ↩

-

Understand how the supplier’s location can influence both pricing and shipping fees. ↩

-

Learn tips and strategies for negotiating with suppliers while maintaining quality. ↩

-

Understand how tiered pricing and bulk purchase discounts can lower the cost of custom bags. ↩

-

Explore ways to maintain product quality and avoid compromising on materials or construction. ↩