How One-Piece Forming Creates Stronger, Seamless Paper Bags

Most people think paper bags are all made the same. Fold a few times, glue it shut, job done — right? Not really.

Traditional paper bags are usually made by hand. Workers fold the bottom, press the sides, add glue, sometimes even add extra reinforcement paper. It’s slow, and the final result depends on who’s doing the folding.

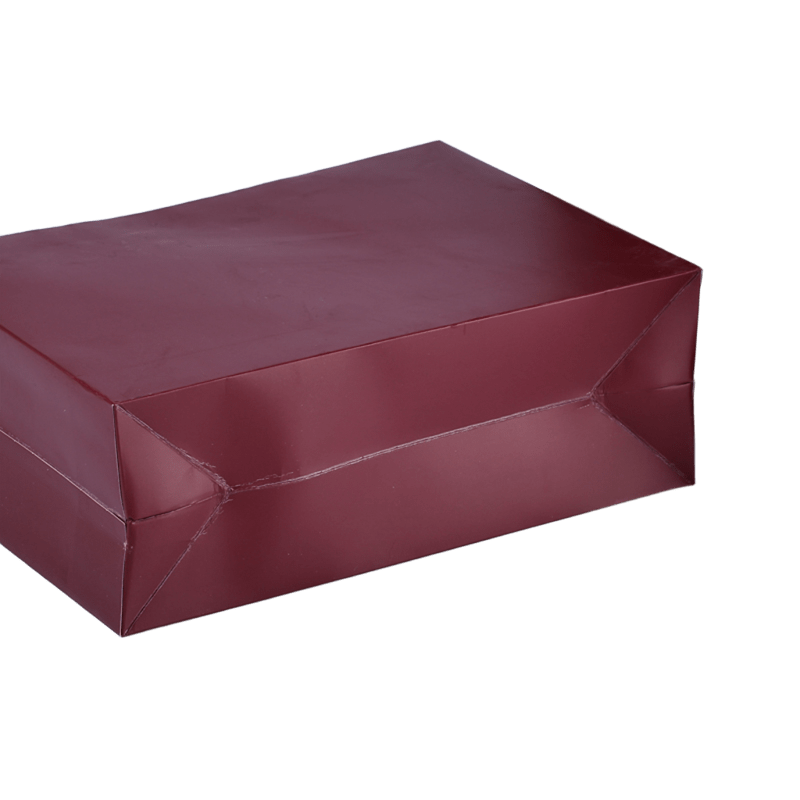

But waistline-free paper bags are made differently. They’re produced by machine, formed in one step from a single sheet of paper — with no visible “waistline,” no patch, and no hand folding.

Let’s take a look at how this is done.

🛠️ What Makes One-Piece Forming So Special?

The magic starts with the material: not a paper roll, but a stack of individual sheets, just like textbooks laid neatly on a school desk.

Each sheet is pre-cut and stacked, waiting to be fed into the machine. This is different from traditional paper bag machines that work with continuous rolls. The one-sheet feeding method improves accuracy and keeps everything clean.

Before production starts, workers adjust the machine (called 调机) to match the sheet size, paper type, glue location, and folding depth.

Then the show begins.

🧩 How It Works — Step by Step

Here’s how that one flat sheet becomes a strong, seamless paper bag:

-

One Sheet Feeds In

- Paper is picked from a stack (not unrolled from a cylinder).

- Each sheet is aligned for folding and gluing.

-

Bottom is Folded, Not Added

- Instead of gluing on an extra piece, the same paper sheet is folded into a strong base.

- It’s like tucking in a cardboard box, but more precise.

- Hot melt glue is used at key points to hold the structure.

-

Sides Folded, Formed as Tube

- Side gussets are created from the same sheet — no extra panels.

- The body is sealed on one vertical seam — no need for a mid-body reinforcement or “waistline” patch.

-

Bag Takes Shape — All in One Pass

- No stopping for patching, no flipping back and forth.

- What comes out is a clean, boxy, strong bag — ready for handles or branding.

This whole process happens on one machine, in one go. No transfers, no extra stations. That’s why we call it 一体成型 (one-piece forming).

💪 Why This Bag Is Stronger

Let’s be honest — paper isn’t steel. So how do we make a paper bag that doesn’t collapse with a takeout box or milk carton inside?

Simple: remove the weak spots.

- No waistline fold = less tearing risk

- No glued-on bottom = fewer seams to fail

- Hot melt glue = faster bonding, no soggy corners

- Stronger base folds = holds weight better

- Flat bottom = better stacking on shelves or counters

You don’t need fancy science to see the difference. Just load it up — the one-piece bag stands taller, lasts longer, and looks better.

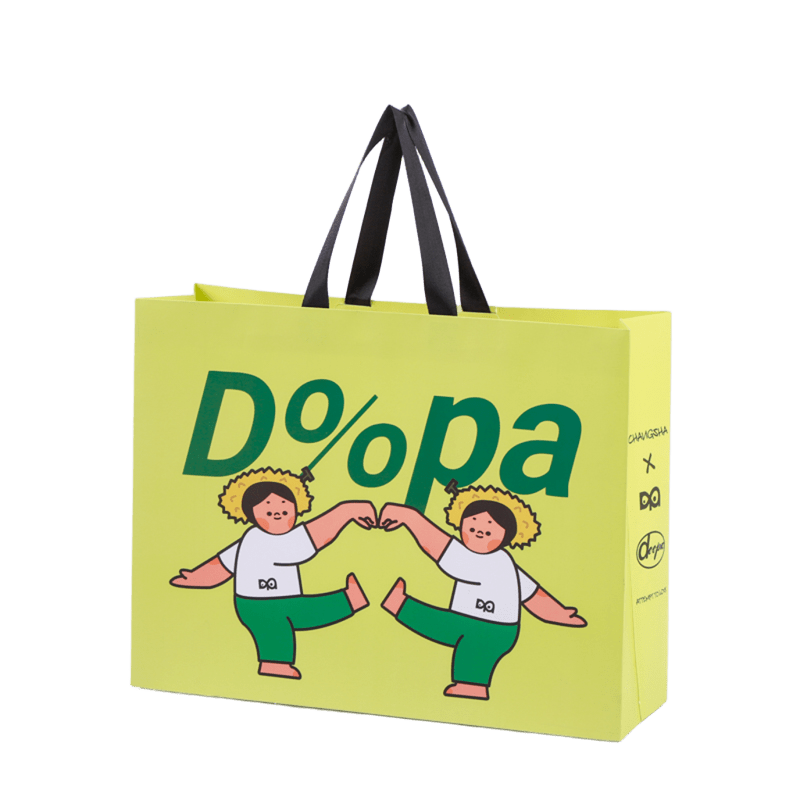

🎨 Perfect Canvas for Custom Printing

Traditional hand-folded bags often show wrinkles, glue marks, or misaligned seams — not ideal for logos.

But the one-piece bag has:

- A smooth surface with no mid-fold interruptions

- More room for QR codes, full-color prints, or big logos

- Cleaner lines = better brand feel

- Flat panels = better for machine-packing

This is the kind of bag that looks good on a retail shelf or in a customer’s hand. And when they reuse it — free advertising!

♻️ Less Waste, More Value

Besides structure and looks, there’s another win: eco-friendliness.

- One-piece forming uses less paper (no reinforcements)

- Uses just the right amount of hot melt glue

- Makes consistent bags with lower rejection rates

- Customers are more likely to reuse bags that don’t break

So if your business wants greener packaging — this is a strong choice without sacrifice.

✅ Summary: Strong, Clean, and Smarter

Waistline-free paper bags aren’t just about looks. They’re about how a single sheet of paper becomes a strong, professional bag — with no patches, no hand folding, and no wasted steps.

They offer:

- Better structure

- Faster production

- Lower material waste

- Cleaner printing

- A modern, minimal look

All that — made by one machine, from one flat sheet, with just the right touch of engineering.

JiaRong Packing

Engineered Bags, Trusted by Businesses Across Asia

www.zjjrpackaging.com

Email: [email protected]

YouTube: https://www.youtube.com/@JR-PAK