What Printing Methods Are Commonly Used on Cooler Bags?

Printing plays a key role in cooler bag customization1. Companies use different methods depending on design complexity2, fabric type, cost, and durability3. Understanding the main

More than 10+ years shopping bag experenice to meet your needs

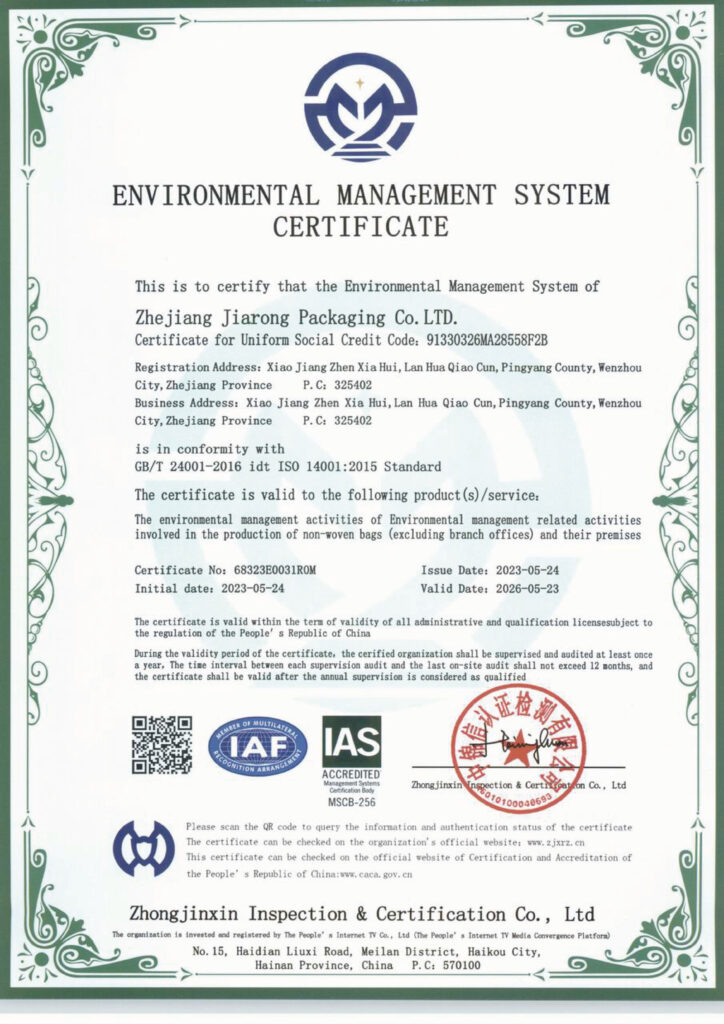

At JiaRong Packaging, we specialize in the production of high-quality non-woven bags designed to meet diverse needs across industries. Whether for personal use, retail, or commercial applications, our non-woven bags are crafted to deliver exceptional durability, eco-friendliness, and practicality.

Not sure about your clothing bag needs or have a unique idea in mind? Let’s discuss!

Our experienced team is here to guide you through the process, ensuring the design and creation of clothing bags that perfectly align with your brand and business needs. With your vision and our expertise, we’ll collaborate to deliver the ideal solution.

As a professional clothing bag manufacturer, we offer fully customizable services, including size, color, logo printing, and functional features. Whether you need bags for fashion retail, promotional events, or brand packaging, we’ve got you covered!

Full Customization Service

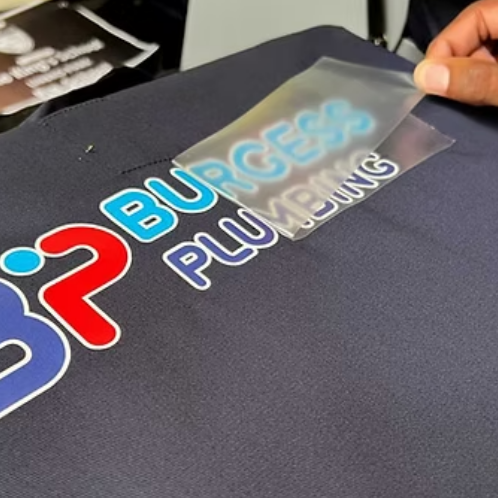

Steps for Silk Screen Printing

1. Choose the In-Stock Bag Style

Select from our ready-made non-woven clothing tote bags.

2. Confirm Your Logo Design

Send us your logo file (AI, PDF, or high-resolution PNG). We will review the design for printing suitability and prepare the layout.

3. Approve the Print Position and Size

Choose where you want the logo to appear (front center, bottom right, etc.) and confirm the print size and color.

4. Silk Screen Printing

Using professional machines, we apply your logo onto the bags with durable, eco-friendly ink. The print is clear and long-lasting.

5. Drying and Quality Check

After printing, the bags are air-dried or heat-dried, then checked to ensure clean prints and no smudging.

6. Packing and Shipping

Printed bags are packed according to your packaging requirements and prepared for dispatch.

Size Customization We offer various bag sizes tailored to your specific needs for different purposes.

Color Options Choose from a wide range of colors to match your brand identity or event theme.

Printing Design High-quality printing for logos, slogans, or designs, ensuring vibrant and durable results.

Material Thickness Multiple thickness options are available to suit different load capacities and usage scenarios.

Special Features Add waterproof coatings, dustproof layers, or eco-friendly biodegradable materials.

Packaging Requirements Individual packaging, bundled packing, or custom cartons to meet your logistics and display needs.

| Types of Customization | Minimum Order Quantity | Production Lead Time | Unit Price | Pricing Standards |

|---|---|---|---|---|

In-Stock Bags with Logo Printing | Usually lower | About 15 days | The price is usually higher for small orders | Printing cost depends on the number of colors and whether it’s single or double-sided |

Full Customization Service | The usual MOQ is 5,000 pieces. | About 30 days | Usually Lower | Pricing depends on bag dimensions, material, color printing, and total quantity |

Our product range goes far beyond standard non-woven bags.

We offer a diverse selection of high-quality, eco-friendly packaging solutions, including laminated non-woven bags, ultrasonic-sealed tote bags, and drawstring garment bags. At the core of our operations is a commitment to timely delivery, exceptional product quality, and fully customizable options tailored to your business needs. This dedication to excellence has earned us a strong and growing reputation in the non-woven bag manufacturing industry.

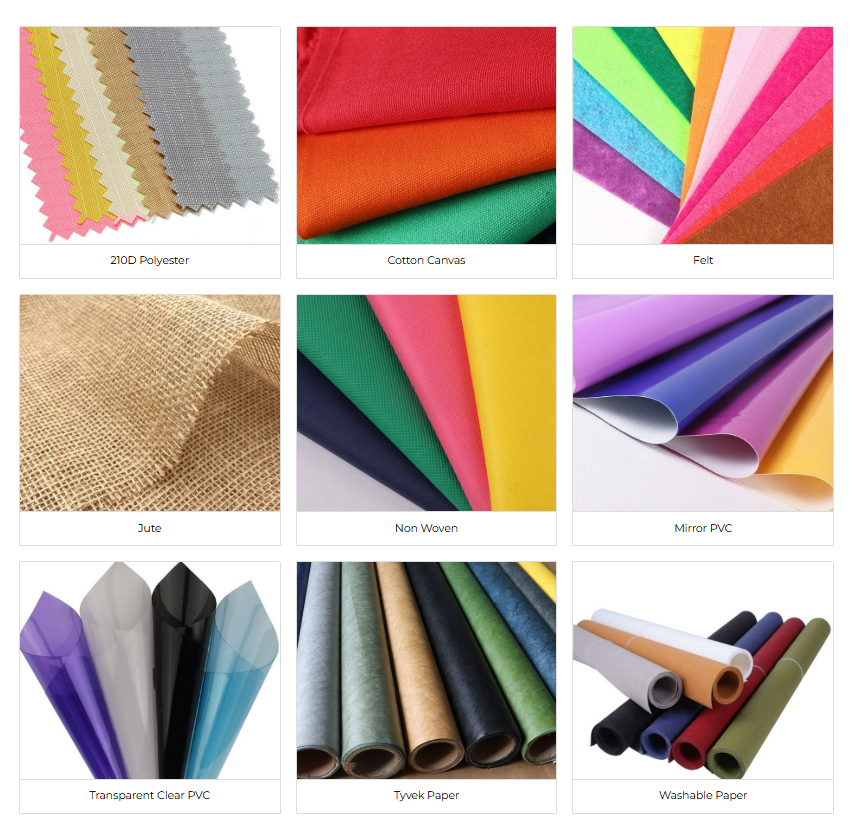

Wide Selection of Materials

We offer a diverse range of materials for your packaging needs, including PP woven fabric, non-woven fabric, canvas, aluminum foil, and more. Each material is carefully selected to provide the perfect balance of durability, eco-friendliness, and style.

Diverse Product Lineup

We offer a broad range of packaging solutions to meet the varying needs of your business. From PP woven shopping bags, non-woven bags, and canvas bags to aluminum foil insulated bags, we provide durable and eco-friendly options for every occasion.

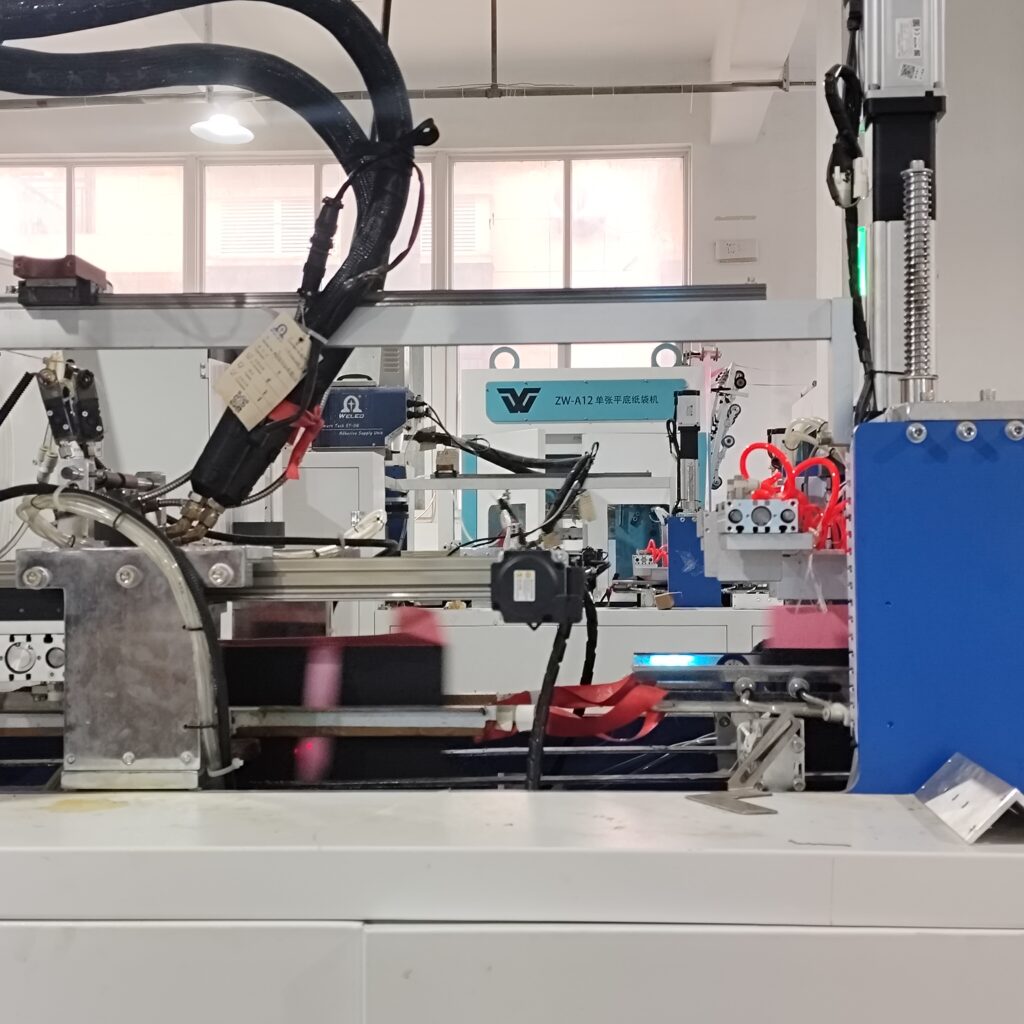

Fabrication and Machining

With years of expertise in the packaging industry, trust us to carefully craft and customize your non woven shopping bags to meet your exact specifications. Our experienced team uses advanced machinery and techniques to ensure precision, durability, and a flawless finish, delivering packaging solutions that perfectly align with your brand and business requirements.

Unmatched Technical Support

If you have any questions about our products or services, we’re here to help. Whether you need advice based on previous projects or require on-site assistance with your packaging needs, our team is ready and equipped to provide the support you need. We are committed to ensuring that your experience with us is smooth and that you receive the best possible solution for your business.

Why Choose JiaRong Packaging as Your Non-Woven Bags Supplier?

Choosing the right non-woven bag manufacturer is key to ensuring quality, efficiency, and brand consistency. JiaRong Packaging stands out as a trusted supplier of custom non-woven bags for global businesses.

With over 15 years of manufacturing experience, we offer:

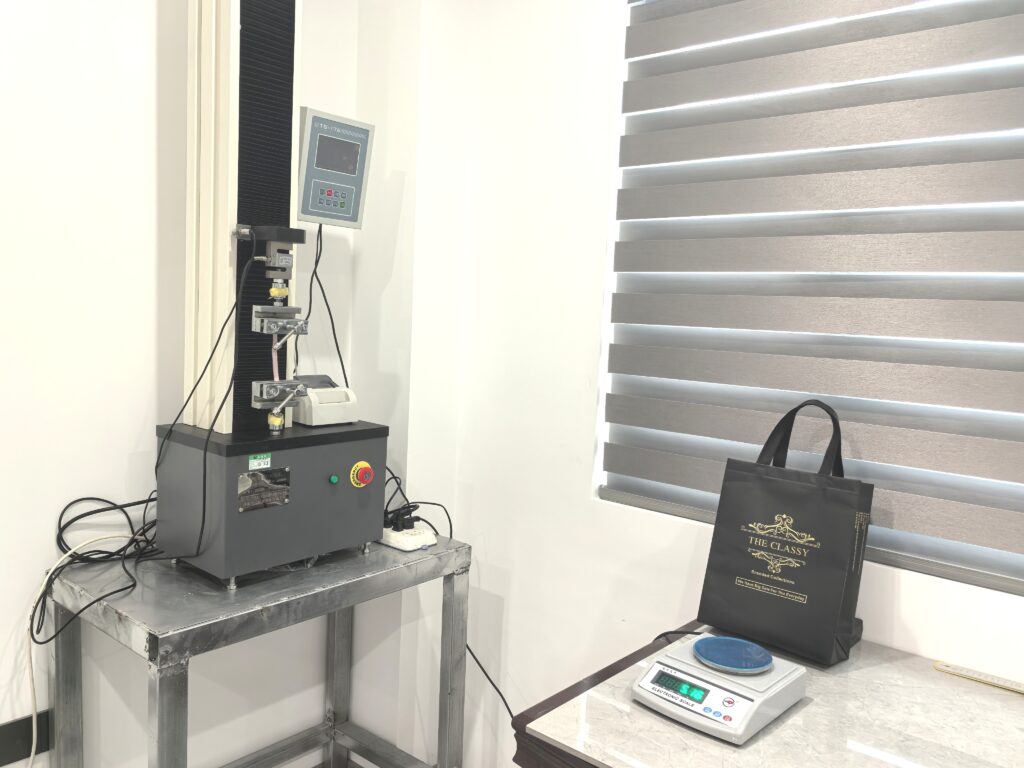

Worried about product quality? JiaRong Packaging is ISO 9001:2015 certified, ensuring every product meets international standards for consistent and reliable quality.

Concerned about production limits? With over 16,000 square meters of factory space and advanced equipment, we can handle orders of any size, from small batches to large-scale production.

Need a variety of packaging solutions? We offer a wide range of bags including non-woven bags, PP woven bags, aluminum foil insulation bags, and more, catering to supermarkets, hotels, restaurants, and various industries.

Unsure about quality? We enforce stringent quality control at every stage, from raw material sourcing to final production, ensuring every product meets the highest standards.

Looking for a reliable partner? JiaRong Packaging has earned multiple honors, including the “Industrial Science and Technology Innovation Award” and “AAA Credit Enterprise,” reflecting our strength and credibility.

Planning to expand globally? Our products are exported to Europe, the U.S., Asia, and other regions, giving you the confidence of working with a partner equipped for international markets

Non-woven bags are widely used in retail, packaging, promotions, and daily shopping. They offer a reusable, cost-effective, and eco-conscious alternative to plastic. Whether you’re sourcing bulk non-woven bags for your brand or building a wholesale supply network, this definitive guide will help you make smart, informed choices.

A Practical and Eco-Friendly Packaging Solution

A non-woven bag is a reusable, lightweight, and eco-friendly bag made from non-woven polypropylene (PP) fabric. Unlike woven fabrics made by interlacing threads, non-woven fabric is produced by bonding fibers together through heat, pressure, or chemical methods.

These bags are popular for shopping, promotional, and garment packaging because they are durable, cost-effective, and highly customizable.

One advanced technique used in making non-woven bags is ultrasonic sealing. Instead of sewing, high-frequency ultrasonic waves bond fabric layers without needles or thread.

Stronger, cleaner seams without stitch holes

Faster production with uniform finishes

Better hygiene since no holes allow dust or bacteria

Ideal for box-style bags, gusseted totes, and garment bags

Reusable and recyclable, supporting sustainability

Lightweight yet durable for daily use

Customizable in size, color, printing, and structure

Cost-effective, suitable for retail, fashion, and promotional uses

Ultrasonic sealing is a modern manufacturing process that uses high-frequency ultrasonic vibrations to join materials—commonly thermoplastics like non-woven polypropylene—without the need for needles, thread, or adhesives. Instead of sewing, the ultrasonic waves create localized frictional heat that melts and fuses the fabric layers together, forming a strong, airtight bond.

An ultrasonic horn emits vibrations at frequencies typically between 20 kHz and 40 kHz. When pressed against the fabric layers, these vibrations generate heat through mechanical friction. The heat melts the thermoplastic fibers at the contact points, bonding the layers firmly as they cool.

Ultrasonic sealing uses high-frequency vibrations to fuse non-woven fabric layers without sewing thread. This technique creates clean, strong, and waterproof seams, making it popular for manufacturing garment bags and tote bags.

No stitch holes, preventing dust and bacteria entry

Faster production with consistent seam quality

Strong, durable bonds that often outperform sewn seams

Environmentally friendly—no thread or adhesives needed

Thickness constraints: Thick or multilayer materials may have weak or uneven seals.

Design limitations: Complex shapes or heavy decorations can be challenging.

Load-bearing weakness: Ultrasonic seams on garment bags, especially on handles, cannot withstand strong lateral (sideways) pulling forces. This means the bag handles sealed by ultrasonic welding are less resistant to side pulls compared to sewn handles, which can limit durability in some usage scenarios.

Therefore, Proper usage is essential for tote bags made with ultrasonic technology to maintain strength and longevity

How Non-Woven Fabric is Made

Non-woven fabric, the main material used in non-woven shopping bags, is created through a unique process that differs from traditional weaving or knitting. Instead of interlacing threads, non-woven fabric is made by bonding short fibers or filaments together using heat, chemical treatment, or mechanical pressure.

Polypropylene (PP) Resin Feeding

The process begins with polypropylene pellets (a type of plastic), which are melted into liquid form.

Spinning into Filaments

The melted resin is extruded through fine nozzles to form long continuous fibers.

Web Formation

These fibers are laid down randomly on a conveyor belt to form a web-like sheet.

Bonding the Web

The fiber web is then bonded using one of the following methods:

Thermal bonding (using heat and pressure)

Chemical bonding (using adhesive agents)

Mechanical bonding (such as needle punching)

Finishing

The fabric is then pressed, trimmed, and rolled. Optional treatments like UV resistance, color pigmentation, or lamination (glossy or matte) can also be applied.

🛍️ Eco-Friendly: Reusable and recyclable, a better alternative to plastic bags

💪 Durable Yet Lightweight: Strong enough to carry daily goods without tearing

🎨 Customizable: Easy to print logos, choose colors, add lamination, handles, zippers, and gussets

💼 Cost-Effective: Ideal for large-scale promotions, retail stores, fashion packaging, and exhibitions

Outer Material:

Durable, lightweight non-woven polypropylene (PP) fabric, eco-friendly and ideal for shopping and garment bags.

Water Resistance:

Glossy or matte lamination adds a protective layer that makes the bag water-resistant and enhances print quality.

Inner Structure:

No insulation materials like aluminum foil or foam, keeping bags light and breathable.

Design:

Customizable sizes, colors, handles, and printing to fit your needs.

Materials are cut into specific shapes and sizes based on the design and dimensions of the non-woven bag.

Computer-controlled cutting machines ensure high precision and consistency, reducing material waste and improving efficiency.

Layering: The outer non-woven fabric and any additional layers (such as laminated film) are layered together to form the main body of the bag.

Joining: Layers are bonded using industrial sewing machines or ultrasonic sealing machines, depending on the bag design and required strength.

Handle and Closure Attachment: Handles, snap buttons, Velcro, or zippers are added to complete the bag and provide secure carrying and closure options.

After passing quality inspection, the non-woven garment bags are folded and packed for shipment.

They are typically stacked and bundled into cartons, ensuring easy handling and protection during export.

At JiaRong Packaging, our advanced equipment and experienced team ensure efficient production, delivering custom solutions tailored to our customers’ needs.

Non-woven garment bags are commonly printed using screen printing, heat transfer printing, Gravure Printing, and digital printing. Each method has its own advantages and suits different design and production needs. Below is a comparison of these four printing techniques:

| Printing Method | Process | Best For | Features | Cost |

|---|---|---|---|---|

| Screen Printing | Ink is applied through a stencil or mesh directly onto fabric. | Simple designs with fewer colors | Cost-effective, durable, bold prints, ideal for logos/text. | Low for small orders |

| Heat Transfer | Designs are heat-pressed from transfer paper to fabric. | Intricate or multi-color designs | High-resolution, vibrant colors, suitable for premium uses. | Medium |

| Gravure Printing | Prints on film laminated onto fabric using gravure cylinders. | Complex, full-color designs | Photo-like images, durable, water-resistant, ideal for bulk. | High initial cost |

| Digital Printing | Ink is printed directly onto fabric via digital printers. | Low-volume, detailed designs | No plates needed, fast, flexible customization. | Higher for small runs |

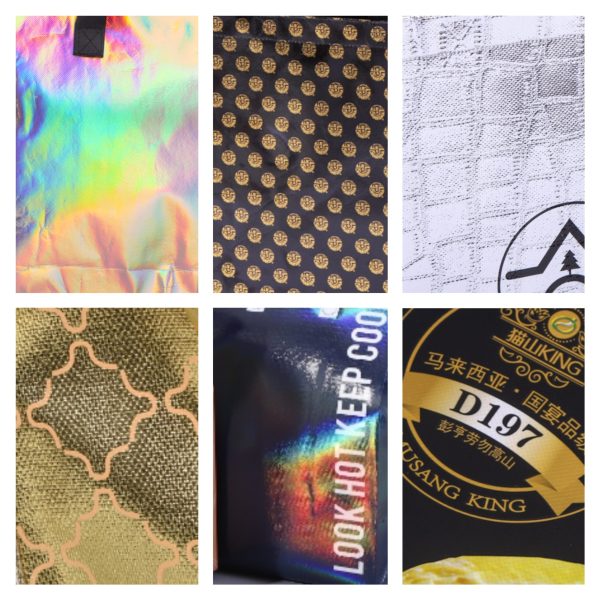

Beyond the standard production steps, non-woven garment bags often undergo additional processes to improve durability, appearance, and customization options. These processes include:

To meet different functional and branding needs, non-woven garment bags can be enhanced with various additional processes, including:

Embossing or foil stamping for a premium finish

Custom labels or QR code tags for branding and tracking

Lamination options such as matte lamination, glossy lamination, and holographic (hologram) lamination to enhance water resistance, texture, and visual impact

These enhancements improve both durability and aesthetics, making the bags perfect for retail, promotional, and garment packaging uses.

Here are some common sizes for your reference

The cost of non-woven bags varies depending on several factors, which can influence material selection, production processes, and customization requirements. Below are the primary factors affecting their pricing:

Fabric Quality: Higher-grade non-woven materials (e.g. thicker GSM or laminated non-woven) cost more than basic options.

Lamination: Laminated non-woven fabric is more durable and water-resistant, but adds to material and processing cost.

Handles and Accessories: Reinforced handles, inner linings, or closures (e.g. Velcro, zippers) also impact cost.

Logo Printing: Options like silk screen printing, heat transfer, or full-color lamination vary in cost depending on the number of colors and design coverage.

Color Matching: Custom Pantone colors may require special ink mixing, which adds cost.

Extra Features: Add-ons like button closures, card slots, or sewn-in labels increase pricing.

While non-woven bags are practical and versatile, they may face certain issues during production, transportation, or daily use. Below is a list of common problems and their potential solutions:

By understanding these common issues and their solutions, customers can better care for their non-woven bags, ensuring longer use and maintaining the bag’s appearance and functionality. Clear communication between suppliers and buyers also helps minimize problems and improves overall satisfaction.

Below is a comparison of the features, advantages, and limitations of three popular clothing bag materials:

| Item | Non-Woven Bags | Paper Bags | PP Woven Bags |

|---|---|---|---|

| Material | Polypropylene (PP) non-woven fabric | Kraft paper / coated art paper | Polypropylene (PP) woven fabric |

| Durability | Medium – suitable for light to medium loads | Low to medium – easily torn when wet | High – extremely durable and tear-resistant |

| Water Resistance | Some water resistance (especially laminated) | Poor – easily damaged by water | Excellent – especially when laminated |

| Reusability | Reusable multiple times | Limited reusability | Long-term reusable |

| Eco-Friendliness | Recyclable, reusable, partially biodegradable | Recyclable and biodegradable | Recyclable, often made from recycled PP |

| Printing Options | Screen printing, heat transfer, lamination | Offset, flexographic, or screen printing | Lamination (OPP film), screen printing |

| Common Uses | Retail, clothing packaging, promotions, shopping | Boutiques, takeaway packaging, gift wrapping | Supermarkets, promotions, heavy-duty packaging |

| Cost Level | Low to medium | Low to medium (depending on paper weight) | Medium – higher cost but longer lifespan |

| Load Capacity | Light to medium | Light | Medium to heavy |

| Appearance & Texture | Soft feel, available in matte or glossy finishes | Natural eco-friendly appearance | Glossy finish with woven texture |

Features:

Made of lightweight, durable polypropylene (PP) non-woven fabric.

Water-resistant (especially laminated) with stitched or heat-sealed handles.

Customizable colors and printing options.

Pros:

Eco-friendly, reusable, and recyclable.

Affordable and suitable for bulk orders.

Good strength for carrying clothing items.

Great for retail, packaging, and promotions.

Cons:

Features:

Made from kraft paper or coated art paper.

Natural, eco-friendly appearance with smooth or textured finish.

Supports various printing methods for branding.

Pros:

Biodegradable and recyclable.

Premium look and feel, great for boutiques and gift packaging.

Lightweight and easy to carry.

Cons:

Features:

Made from woven polypropylene (PP) fabric, often laminated for extra strength.

Strong, durable, and water-resistant with a textured woven surface.

Handles made from the same woven fabric or reinforced webbing.

Pros:

Very durable and tear-resistant, suitable for heavy loads.

Water-resistant and reusable for long-term use.

Cost-effective for large orders with good lifespan.

Cons:

Less eco-friendly than paper or some non-woven bags unless recycled material is used.

Appearance can be less premium compared to paper bags.

Heavier and bulkier than non-woven bags.

Purchasing Non woven shopping bags requires careful planning and clear processes to ensure cost-efficiency, quality, and timely delivery. Here’s a step-by-step guide to streamline the procurement process:

By following these steps, businesses can ensure a smooth procurement process and secure high-quality PP woven shopping bags at competitive prices. At JiaRongPackaging, we offer professional manufacturing services, reliable quality control, and tailored solutions to meet your procurement needs. Contact us today to get started!

Printing plays a key role in cooler bag customization1. Companies use different methods depending on design complexity2, fabric type, cost, and durability3. Understanding the main

Cooler bags are popular for shopping, outdoor activities1, and food delivery2, but many buyers misunderstand the materials used in their construction. This article clears up

Cooler bags are essential in daily life, from picnics and camping to supermarket shopping and food delivery. Selling them globally requires smart distribution strategies that

The European cooler bag market1 in 2025 shows strong demand for stylish, multifunctional, and durable designs. In this article, we explore six popular cooler bag

Cooler bags are no longer just picnic accessories. They have become daily essentials for professionals, families, and outdoor enthusiasts. In this article, we explore seven

Understanding lead times1 for custom bulk orders is key to planning ahead. This article explains standard production2 timelines, fast options, and factors that affect delivery

Contact us for a free quote and more expertise on custom tote bags. Together with Jiarong Packaging, we will find the right solution for your project.

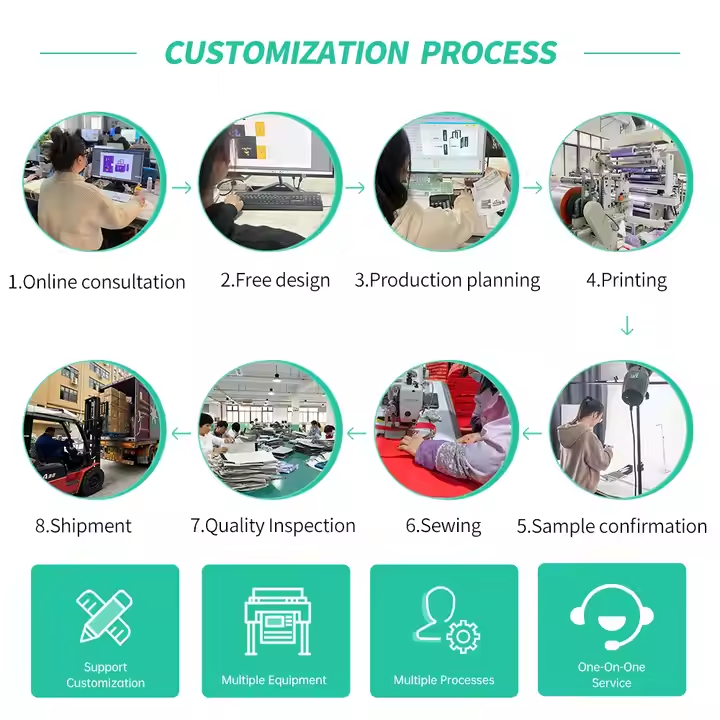

At Jiarong Packaging, we make it simple! Follow these 3 steps to get started today!

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

We will start mass production after getting your approval and deposit, and we will handle the shipment.

Jiarong Packaging - Non-woven and Insulated Bag Manufacturer

Typically replies within minutes

Any questions related to Non-Woven Clothing Tote Bag?

WhatsApp Us

🟢 Online | Privacy policy

WhatsApp us

We’ll reach out to you within 8 hours. Please keep an eye out for an email from us, coming from the address ending in “@zjjrpackaging.com”

Don’t go away, there are free samples available here. Please leave your email address so I don’t miss you. We’ll reach out to you within 12 hours. Please keep an eye out for an email from us, coming from the Jiarong Packing.