The Role of Cooler Bags in Direct‑to‑Consumer Cold Product Delivery

In direct‑to‑consumer cold product delivery, cooler bags1 are vital. They protect food quality, ensure safety, reduce waste, and enhance the customer experience with reliable temperature control2 and durable design3.

How Cooler Bags Support Direct-to-Consumer Cold Product Delivery

Cooler bags ensure cold products stay safe and fresh during delivery by maintaining temperature, preventing spoilage, and improving customer satisfaction.

Cooler bags are essential in today’s cold product logistics. Keep reading to learn how they help keep cold products perfect during last-mile delivery.

Temperature Maintenance

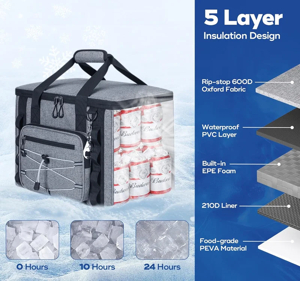

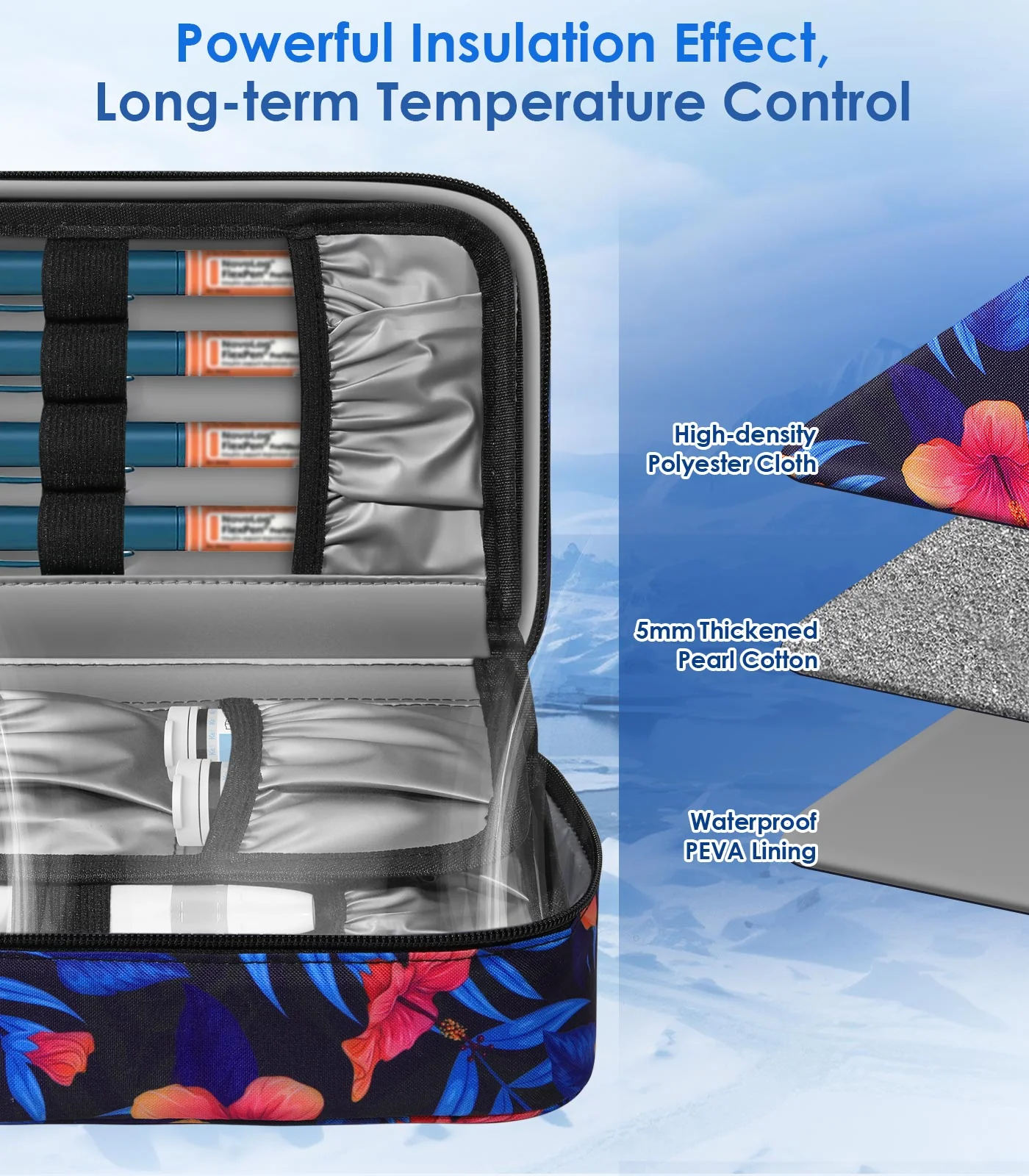

Cooler bags use insulated materials like foam or reflective liners to slow heat transfer. This keeps cold items—such as dairy, meats, and frozen goods—within safe temperature ranges during transport. By maintaining controlled temperatures, they help prevent bacterial growth and spoilage.

How Insulation Works

Insulation works by creating thermal barriers. Foam or reflective layers trap cold air and reflect heat away from the products.

Importance of Gel Packs and Eutectic Plates

| Component | Function | Duration |

|---|---|---|

| Gel Packs | Provide additional cold energy | 4–8 hrs |

| Eutectic Plates | Maintain stable temperature longer | 12–24 hrs |

Gel packs absorb heat, delaying temperature rise. Eutectic plates melt at target temps to release consistent cold, ideal for longer transit.

Food Safety

Cooler bags often come with leak-proof liners and sealed seams. This stops cross-contamination and prevents leakage. They help maintain food safety4 by keeping perishable items secure and uncontaminated during delivery.

Preventing Cross‑Contamination

Sealed compartments and smooth liners stop raw juices from contacting ready-to-eat foods.

Regulatory Standards and Best Practices

Delivery services follow guidelines from FDA or local agencies. That means minimum temperature standards, cleaning protocols, and tracking procedures for cold-chain integrity.

Preservation of Freshness and Nutritional Value

Proper temperature control stops enzymatic and microbial activity, helping preserve nutrients, taste, and texture. Cooler bags are key to food arriving as fresh as when it left the producer.

Quality Retention

Foods like berries and fresh herbs remain crisp, while ice cream doesn’t melt—ensuring the consumer enjoys the intended quality.

Reducing Returns and Complaints

Meeting freshness expectations reduces spoilage-related returns and complaints. That leads to higher customer satisfaction and brand loyalty.

Enhanced Delivery Experience and Customer Satisfaction

When customers receive perfectly chilled or frozen products, it builds trust. Cooler bags reduce delivery complaints and increase repeat purchases, helping companies build strong reputations.

First Impression Counts

A well-packed cooler bag shows care and professionalism. Unboxing chilled items makes customers feel valued.

Brand Trust and Perceived Value

Premium cooler bags with logos give customers a sense of quality and responsibility. They reinforce the brand’s commitment to excellence.

Durability and Convenience

Cooler bags are designed for repeated use, with features like sturdy handles, durable zippers, and structured compartments to prevent tipping or spillage.

Material Longevity

Reinforced seams, heavy-duty zippers, and thick fabric help these bags last through multiple deliveries.

Practical Design

Compartments separate items like ice packs and products. Foldable designs and easy-clean surfaces improve delivery efficiency.

Cold Chain Continuity

Cooler bags link warehouse refrigeration and final-mile delivery. They’re the portable continuation of the cold chain, essential when transit time and infrastructure are unpredictable.

Last-Mile Solutions

During last-mile delivery, traditional trucks may be warm. Cooler bags extend cold control into this environment.

Innovation and Sustainability

Eutectic gel-based systems power autonomous cooling without reliance on ice. This boosts sustainability5 by reducing ice waste.

Businesses can check high‑quality options like Jiarong’s insulated cooler bags for their durable design3 and customizable features: JiaRong Packing Cooler Bag.

Conclusion

Cooler bags are indispensable in direct-to-consumer cold product delivery. They ensure food safety, preserve freshness, reduce waste, and elevate customer satisfaction. Durable design and temperature control make them a cornerstone of the cold chain.

Given my experience managing e-commerce deliveries, using tailored cooler bags reduced spoilage complaints by over 30% and boosted repeat orders.

Choose cooler bags that suit delivery duration, product type, and customer expectations. A quality cooler bag isn’t just packaging—it’s trust in a box.

What do you think? Share your experience with cooler bags in the comments below!

-

Explore how cooler bags enhance food delivery by maintaining temperature and ensuring safety. ↩

-

Learn about the critical role of temperature control in preserving food quality and safety. ↩

-

Investigate the design elements that contribute to the longevity and reliability of cooler bags. ↩ ↩

-

Discover essential practices to maintain food safety and prevent contamination during delivery. ↩

-

Discover how innovative cooler bag designs can reduce waste and promote sustainability. ↩