Top 5 Eco-Friendly Alternatives to Plastic Bags in 2025

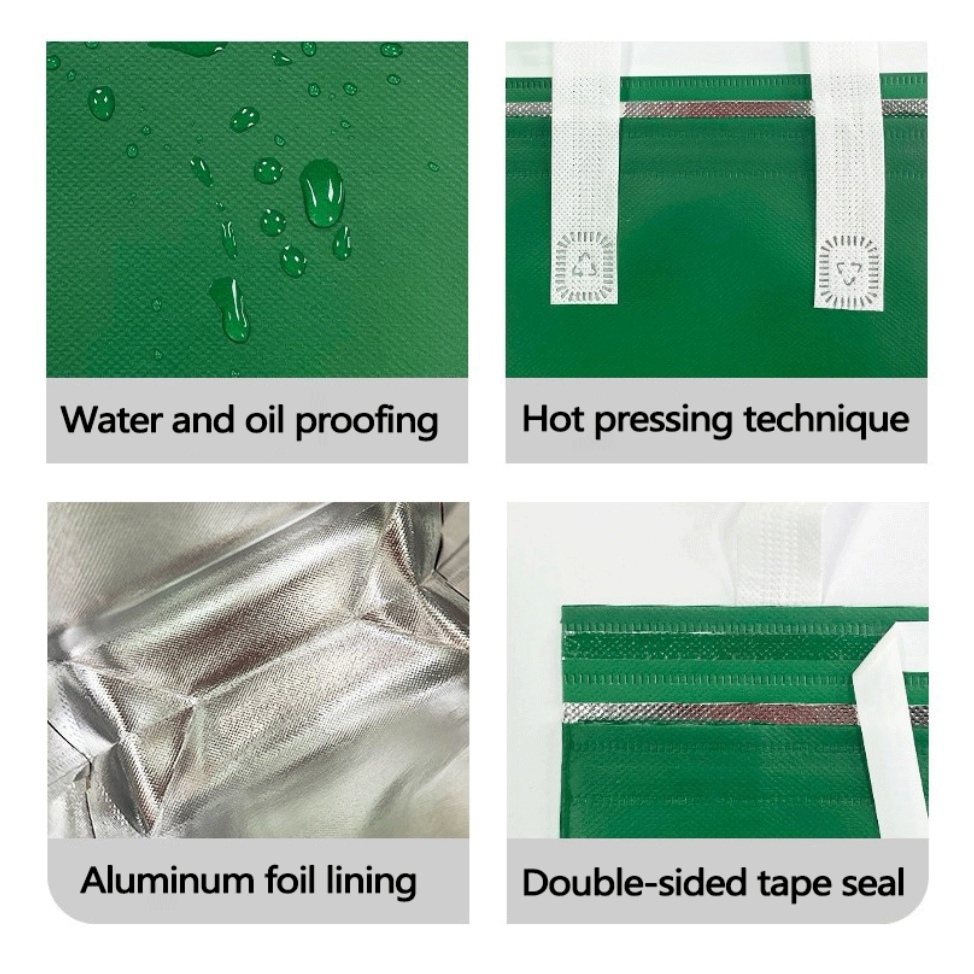

With stricter plastic regulations and rising environmental awareness, 2025 highlights a shift toward sustainable packaging. This list presents the top five eco-friendly alternatives to single-use