Types of Non-Woven Fabric: The Ultimate Guide

Non-woven fabric is everywhere—shopping bags, medical masks, insulation layers, and more.

It's like the quiet hero of modern packaging and textiles: low-cost, flexible, and versatile.

But not all non-woven fabric is the same.

From how it's made to how it's used, each type has a unique role.

Let’s break it down in simple terms.

🧵 What Is Non-Woven Fabric?

Unlike traditional fabric that’s woven from threads, non-woven fabric skips the weaving.

It’s made by bonding fibers directly—either with heat, pressure, or glue.

Think of it like making paper:

Fibers are pressed together into sheets without stitching.

Fast, clean, and efficient.

🌟 Common Types of Non-Woven Fabric

1. Spunbond Non-Woven

This is the most popular type used in shopping bags.

How it’s made:

Plastic pellets (usually polypropylene) are melted, spun into fibers, then pressed into fabric.

Key features:

- Durable

- Breathable

- Water-repellent

- Printable

Use cases:

- Non-woven tote bags

- Medical caps and shoe covers

- Furniture lining

👜 It's the "jeans" of non-woven—everyday, reliable, and everywhere.

2. Meltblown Non-Woven

Very fine fibers, super soft, used mainly for filtration.

How it’s made:

Similar to spunbond, but the fibers are even thinner—like hair turned into mist.

Key features:

- Excellent filter

- Lightweight

- Smooth texture

Use cases:

- Surgical masks (middle filter layer)

- Air filters

- Oil absorbents

😷 Think of it as the “face mask fabric”—thin but powerful.

3. Spunlace (Hydroentangled) Non-Woven

Made by shooting high-pressure water jets onto fiber webs.

Key features:

- Soft and cloth-like

- Strong with no glue

- Absorbent

Use cases:

- Wet wipes

- Facial masks

- Cleaning cloths

🧻 It's like the “towel” of non-woven—gentle yet effective.

4. Needle Punch Non-Woven

Created by mechanically punching barbed needles into fiber layers.

Key features:

- Thick and sturdy

- Good sound and heat insulation

- Washable

Use cases:

- Carpet backing

- Automotive insulation

- Geotextiles for road construction

🚗 It’s the “work boot” of non-woven—tough and built for heavy use.

5. Thermal Bonded Non-Woven

Fibers are melted and pressed to fuse together.

Key features:

- Thin

- Economical

- Soft

Use cases:

- Disposable cleaning cloths

- Hygiene products

- Interlinings in clothes

🛍️ Which Type Is Best for Bags?

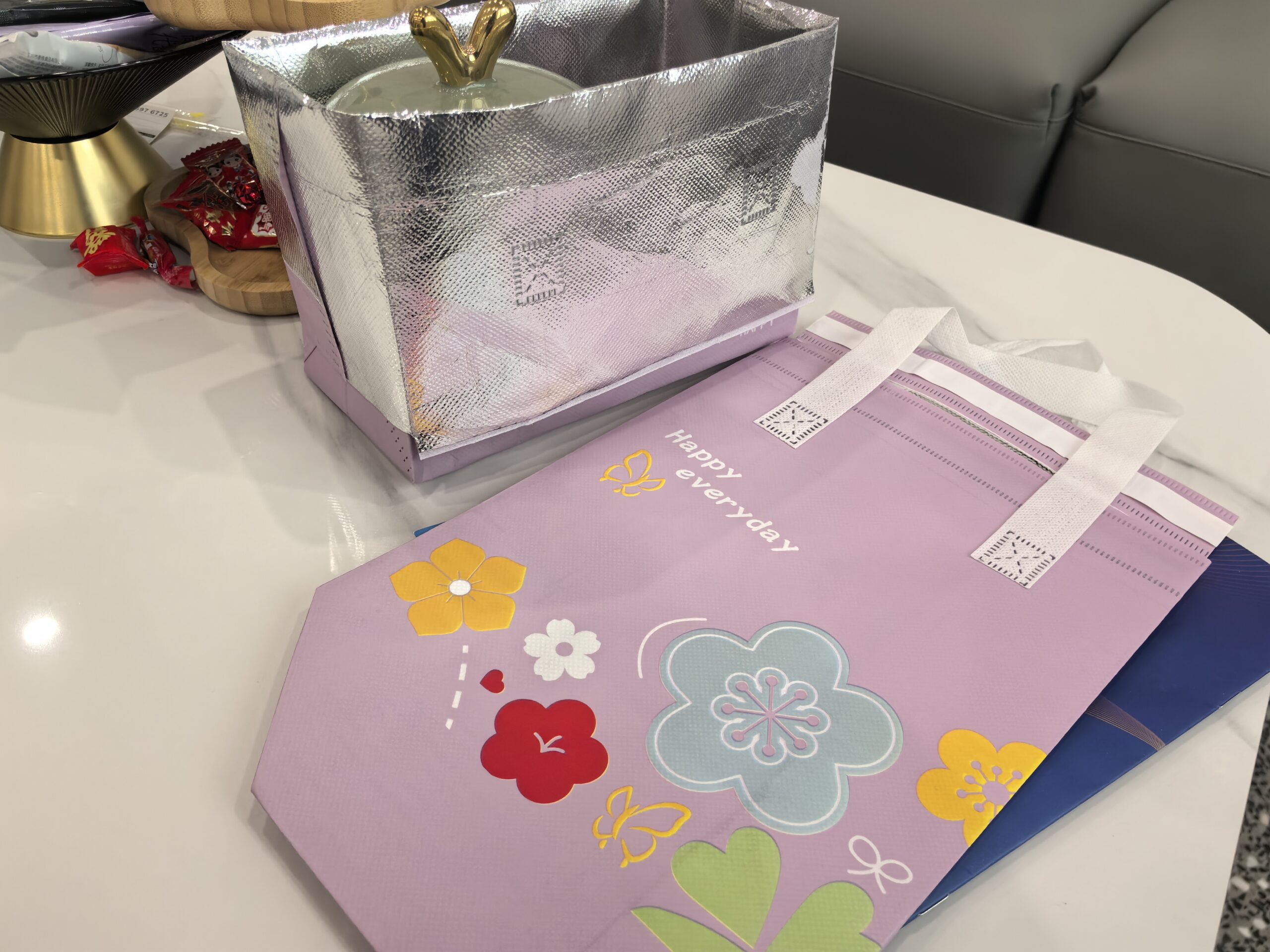

For reusable bags like those from JiaRong Packaging, spunbond non-woven is the top choice.

It strikes the right balance between cost, strength, and printability.

Plus, it comes in many colors and can be laminated for a waterproof surface.

Want it shinier? Choose laminated non-woven.

Need extra insulation? Add foil lining inside.

💡 Final Thoughts

Choosing the right non-woven fabric is like picking the right outfit.

You wouldn’t wear a tuxedo to the beach or flip-flops to a business meeting.

Each type has a purpose.

And when used correctly, it helps products last longer, look better, and work smarter.

Want custom non-woven bags for your brand?

JiaRong Packaging offers design, printing, and production—all in one place.

Visit 👉 https://zjjrpackaging.com

📧 Contact: Effie | [email protected]