Understanding the comparative thermal performance of PE foam and EPE-lined cooler bags helps businesses choose the best insulation material based on durability, heat retention, and cost-effectiveness. This article provides a practical comparison to aid informed B2B decisions.

PE Foam vs. EPE Foam Cooler Bags: Which Insulates Better?

PE foam cooler bags1 offer better insulation and durability than EPE-lined bags, though both materials benefit from multi-layer reflective construction2.

Read on to learn which cooler bag material fits your product needs best in different usage scenarios.

Thermal Insulation and Heat Resistance Comparison

PE foam and EPE foam differ in thermal insulation capacity3 due to their cellular structures and material properties. Understanding their resistance to heat and efficiency in retaining cold helps guide appropriate use.

Heat Resistance and Thermal Performance

| Property | PE Foam | EPE Foam |

|---|---|---|

| Maximum Temperature (°F) | 176 | 158 |

| Foam Structure | Closed-cell | Open-cell |

| Thermal Conductivity | Lower (better insulation) | Higher than PE (less efficient) |

| R-value (for 3mm) | Not always stated | 0.1–0.7 m²·K/W |

PE foam’s closed-cell design provides better protection against heat transfer4 via conduction and convection. EPE, on the other hand, performs well enough for everyday use but falls short in prolonged or extreme heat scenarios.

Real-World Example

PE foam-lined cooler bags are often chosen for transporting perishable food or medicine over longer distances. Their enhanced insulation performance can mean up to 2–4 hours more temperature retention compared to EPE-based bags under similar conditions.

Durability and Strength

When choosing between PE and EPE for cooler bags, durability plays a crucial role in how long the bag can maintain structural integrity and thermal performance after repeated use.

Material Strength and Wear Resistance

| Property | PE Foam | EPE Foam |

|---|---|---|

| Tear Resistance | Medium to strong | Lower |

| Compression Strength | Higher | Lower |

| Reusability | Longer lifespan | Shorter lifespan |

EPE foam tends to degrade more quickly when flexed or compressed repeatedly. PE foam, with its denser cell structure, holds up better under pressure, reducing replacement frequency.

Long-Term Usage Insight

A company requiring bags for cold chain logistics would benefit from PE-lined cooler bags, particularly when bags are reused multiple times. EPE is better suited for single-use or light-duty purposes.

Moisture Resistance and Hygiene

Cooler bags often encounter moisture due to melting ice or cold food. Material moisture resistance directly affects hygiene and reusability.

Moisture and Fungus Resistance

| Property | PE Foam | EPE Foam |

|---|---|---|

| Water Absorption | Very low (closed-cell) | Moderate (can absorb slightly) |

| Mold & Fungus Growth | Resistant | Resistant but more susceptible |

| Chemical Resistance | Strong | Moderate |

PE foam performs better in resisting moisture, making it more hygienic and ideal for environments requiring clean, food-safe conditions.

Practical Application

Catering services or frozen food delivery services prefer PE-based bags for their resistance to moisture buildup and easier internal cleaning.

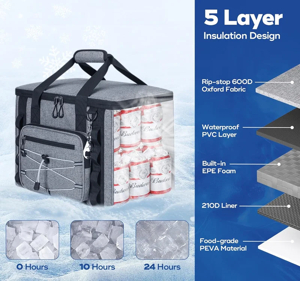

Construction Design and Reflective Layer Integration

The thermal performance of both materials is significantly enhanced by multi-layer construction that includes reflective and waterproof materials.

Bag Composition Strategies

| Layer | Function |

|---|---|

| Outer Waterproof Shell | Keeps moisture out, protects against wear |

| PE or EPE Foam Layer | Insulates by reducing conduction/convection |

| Aluminum Foil Lining | Reflects radiant heat, improves performance |

Reflective foil helps offset EPE’s insulation shortcomings. Many EPE bags integrate a foil liner to maintain competitive thermal performance at a lower cost.

Example Product Structure

Visit our cooler bag product line to explore various multi-layer bag options combining EPE or PE foam with aluminum foil and waterproof linings.

Cost, Sustainability, and Recyclability

While performance is important, businesses also evaluate cost and environmental impact when selecting bag materials.

Cost vs. Recyclability Tradeoff

| Property | PE Foam | EPE Foam |

|---|---|---|

| Initial Cost | Slightly higher | Very low |

| Recyclability | Widely recyclable | Limited |

| Environmental Impact | Moderate | Higher in production |

PE foam’s better recyclability makes it attractive for brands focused on sustainability. EPE remains the go-to for low-budget, high-volume applications where single use is common.

Business Perspective

For promotional giveaways or lightweight product samples, EPE is cost-efficient. For corporate branding or logistics use, PE foam offers better ROI in the long term.

Final Recommendation and Use Scenarios

Choosing the right foam depends on how the cooler bags will be used. Both materials serve different business needs well.

Ideal Use Scenarios

| Application Type | Recommended Material |

|---|---|

| Long-distance food delivery | PE Foam |

| Event giveaways | EPE Foam |

| Reusable supermarket bags | PE Foam |

| Single-use packaging | EPE Foam |

| Cold chain medical transport | PE Foam |

Conclusion

PE foam-lined cooler bags outperform EPE in insulation, durability, and moisture control, making them ideal for long-term, heavy-duty use. EPE foam bags, though less robust, are cost-effective and flexible enough for promotional or light-duty needs. At JiaRong Packaging, we offer both material options with custom branding and design.

You can check out our range of cooler bags at https://zjjrpackaging.com/cooler-bag/. Let us know in the comments which foam material you prefer and why.

-

Discover the advantages of PE foam cooler bags for insulation and durability, helping you make an informed choice. ↩

-

Learn how multi-layer reflective construction enhances cooler bag performance, ensuring your items stay fresh longer. ↩

-

Understanding thermal insulation capacity is crucial for selecting the right materials for insulation, ensuring efficiency and effectiveness. ↩

-

Exploring heat transfer mechanisms can enhance your knowledge of material properties and their applications in insulation. ↩