What Printing Methods Are Commonly Used on Cooler Bags?

Printing plays a key role in cooler bag customization1. Companies use different methods depending on design complexity2, fabric type, cost, and durability3. Understanding the main

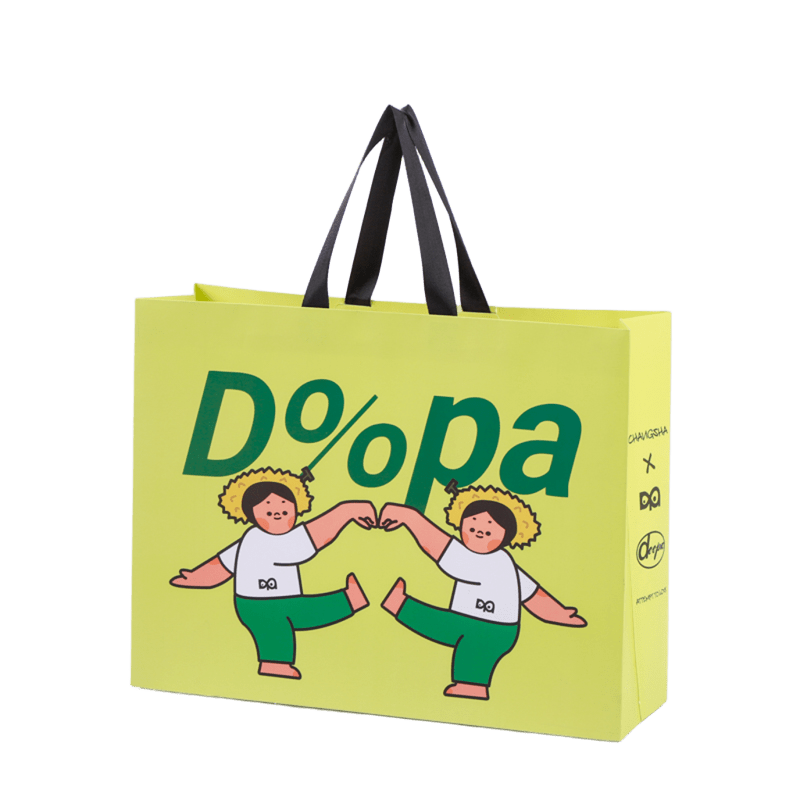

Custom Paper Bags Without Waistline – Stronger, Cleaner, and More Reliable

JiaRong Packaging specializes in high-quality custom paper bags without waistline to meet all your packaging needs. Our products include seamless paper shopping bags, kraft paper bags, gift bags, and retail packaging bags. Whether for retail, supermarkets, or promotions, our waistline-free, reinforced paper bags offer a strong, eco-friendly, and elegant branding solution. Customize size, color, and logo to enhance your brand identity while ensuring superior load-bearing capacity and a clean, glue-leak-free finish.

Say goodbye to visible seams

Our waistline-free paper bags feature a clean, uninterrupted surface that elevates your packaging aesthetics. The seamless design creates a sleek and modern look, making your brand appear more refined and professional. Whether used in retail or high-end gift packaging, this minimalist approach helps your products stand out effortlessly.

Stronger than they look

Crafted with reinforced folding and high-quality paper material, our waistline-free paper bags offer excellent load-bearing performance. Without the weak points caused by glue seams, these bags are reliable for carrying heavy items—ideal for shopping, promotions, and retail packaging that demand both strength and style.

Every detail matters

Our innovative no-waistline structure eliminates glue seams, resulting in a cleaner appearance and better durability. No more visible glue lines or peeling edges—just smooth, professional packaging that reflects your commitment to quality and sustainability. Perfect for brands that care about the little things that make a big difference.

Turn heads with radiant, color-shifting holographic film that transforms ordinary paper bags into premium packaging.

Water-resistant, tear-resistant, and unforgettable — these bags don’t just carry your product, they carry your brand.

Perfect for luxury gifts, fashion, cosmetics, and any brand that dares to shine.

Enhance your packaging with bold, customized colors and ultra-clear printing.

Our advanced printing techniques ensure every logo, pattern, and detail pops — with vivid color accuracy and lasting quality.

Perfect for brands that want to stand out at first glance.

From small gift bags to oversized shopping totes, we offer fully customizable sizes to match your product and purpose.

Whether for retail, events, or packaging solutions, our paper bags are made to measure — because one size never fits all.

At JiaRong Packaging, we specialize in high-quality paper bags without waistline, designed for a sleek appearance and enhanced strength. The seamless structure eliminates glue lines, ensuring a cleaner finish and better durability for everyday and commercial use.

We offer full customization for size, color, and logo printing — including QR code printing directly on the bag for easy digital engagement.

Waistline-free paper bags are widely used in retail, gift packaging, supermarkets, and promotional events, offering a refined, eco-friendly alternative to traditional packaging.

Contact us today to create your custom seamless paper bags that combine style, strength, and smart branding.

Have a unique idea or not sure which bag suits your needs? Let’s talk!

Our expert team is here to help you design and create the perfect custom bags for your brand. With your vision and our experience, we’ll work together to bring practical, high-quality solutions to life.

As a trusted manufacturer of custom bags, we offer full customization — from size, color, and logo printing to functional add-ons. Whether for retail, events, or promotions, we’re ready to meet your packaging needs with flexibility and precision.

📏 Size Customization

Choose from a full range of sizes tailored to your product dimensions and packaging needs — from small gift bags to large retail carriers.

🎨 Color Options

Select from a wide palette of colors to match your brand identity or campaign theme, including natural kraft, white, and full-color printing.

🖨️ Printing Design

High-quality logo, pattern, slogan, or QR code printing with sharp details and vibrant colors for maximum brand visibility.

📄 Paper Weight / Thickness

Various paper grades and thickness options to meet different load-bearing requirements and presentation standards.

📐 Bag Structure

Customize key structural features such as bottom reinforcement, side gussets, folded handles, rope handles, or die-cut handles.

🌿 Eco-Friendly Options

Available in recyclable, biodegradable, or FSC-certified paper to support sustainable packaging goals.

📦 Packaging Requirements

Tailored packing methods — individual bag packing, flat-folded bulk packaging, or custom cartons for safe and efficient transport and storage.

Our paper bags feature a seamless, waistline-free design, crafted from the paper material of your choice. Whether it’s kraft, coated, or specialty paper, we offer a wide range of vibrant colors to perfectly align with your brand identity. Combining a sleek, modern look with customizable materials and colors, our bags deliver both style and durability tailored to your needs.

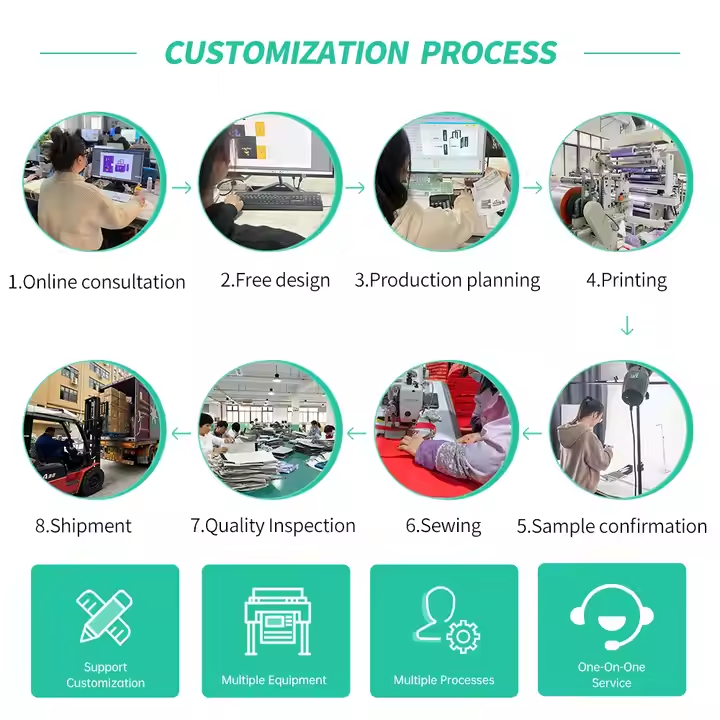

At the core of our business is a strong commitment to timely delivery, consistent product quality, and customized solutions designed to meet your unique branding requirements. This unwavering dedication to excellence has helped us build a strong and growing reputation in the paper packaging industry.

Wide Selection of Paper Materials

We offer a diverse range of high-quality paper materials for your custom bags, including kraft paper, coated paper, specialty papers, stone paper, and more. Each material is carefully chosen to provide the perfect balance of strength, eco-friendliness, and aesthetic appeal, ensuring your paper bags look great and perform reliably.

Diverse Product Lineup

We offer a wide variety of paper bag solutions to suit the diverse needs of your business. From kraft paper bags and coated paper bags to specialty paper and stone paper bags, our products combine durability, eco-friendliness, and style for every occasion.

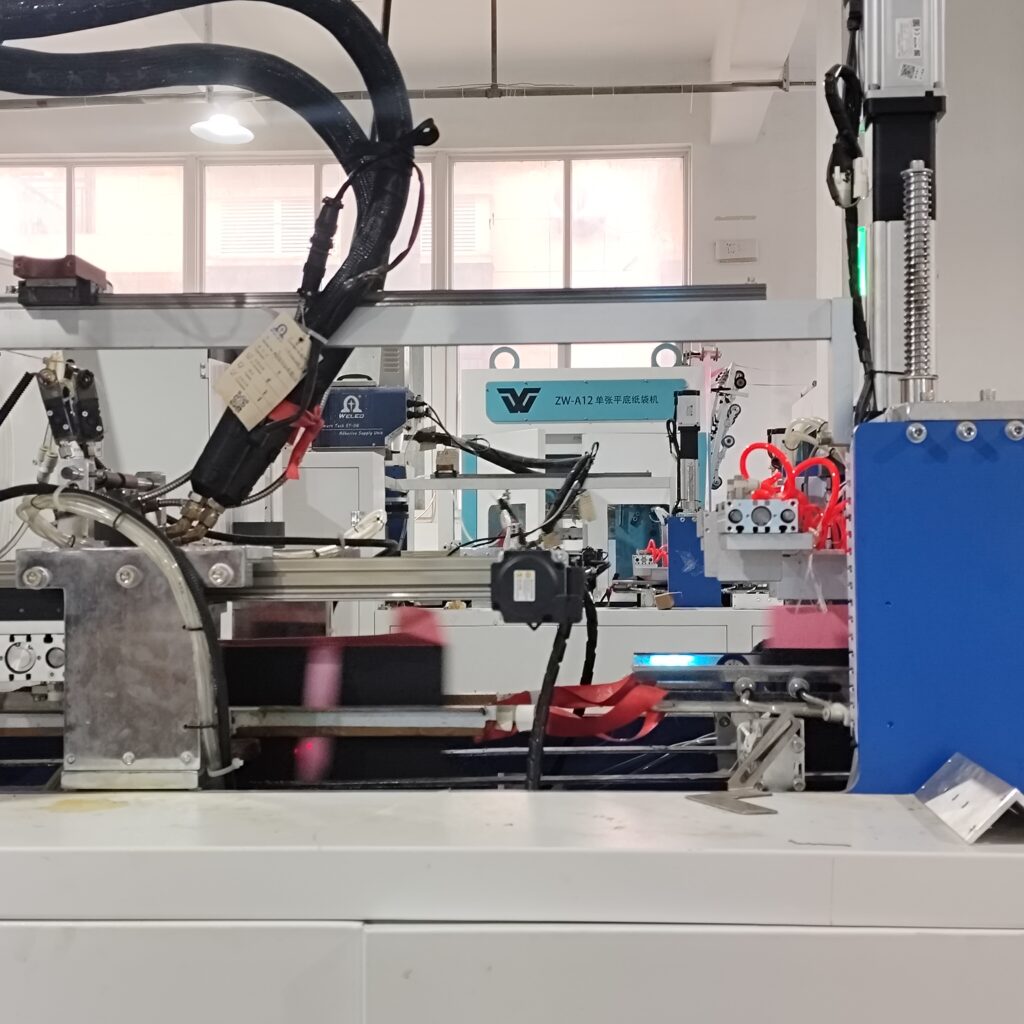

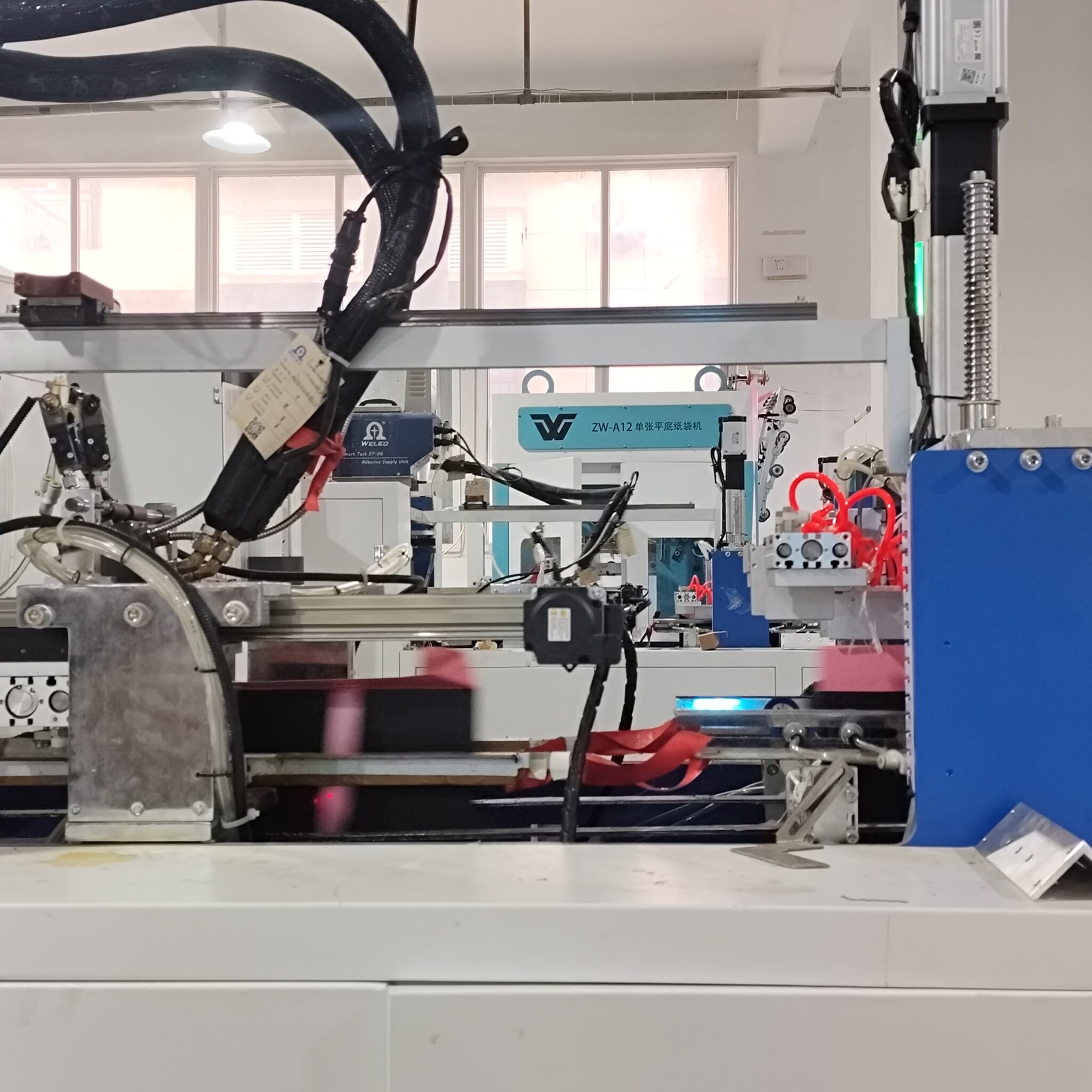

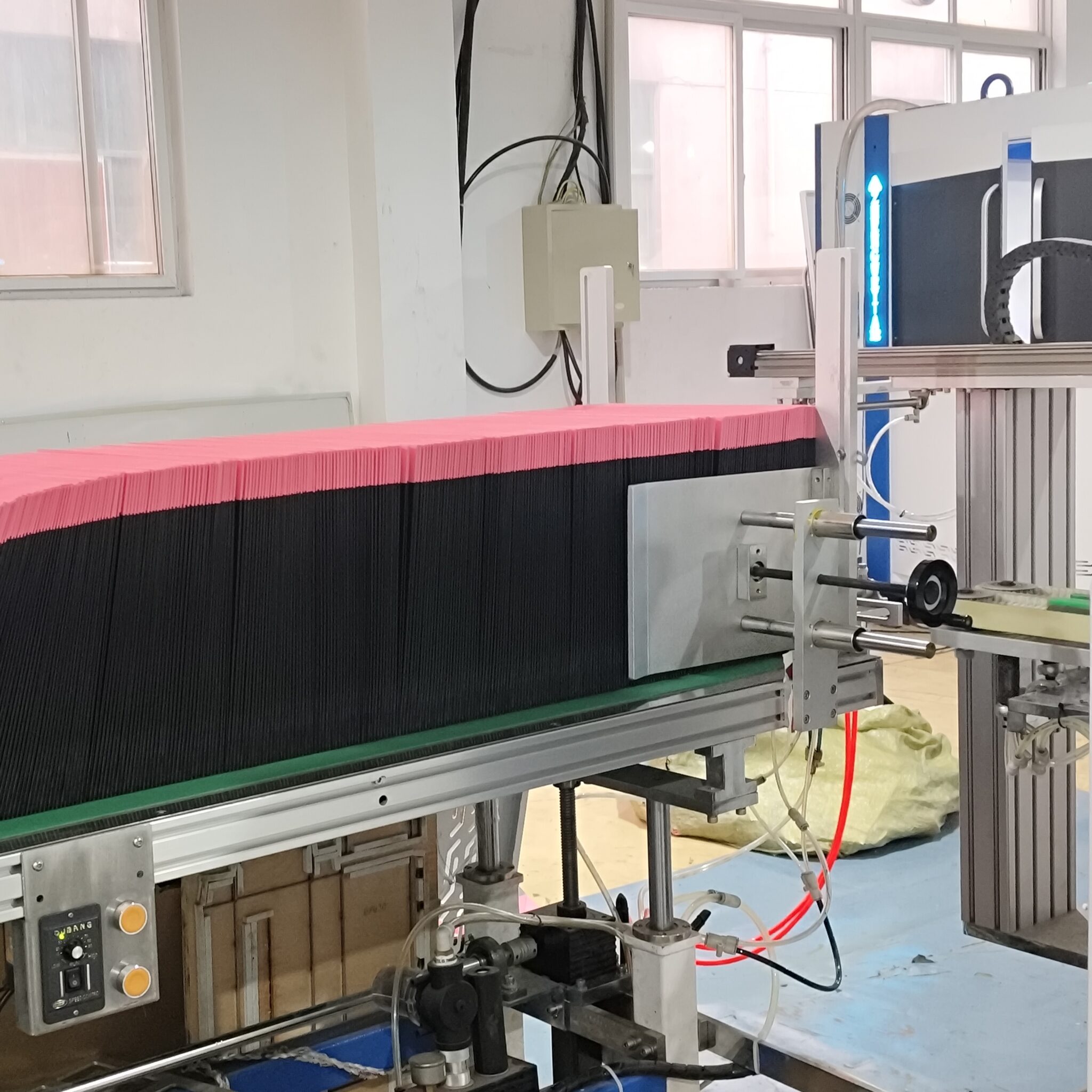

Fabrication and Craftsmanship

With years of experience in the packaging industry, you can trust us to expertly craft and customize your paper bags to meet your exact specifications. Our skilled team utilizes advanced machinery and precise techniques to ensure durability, impeccable quality, and a flawless finish—delivering packaging solutions that perfectly reflect your brand and business needs.

Exceptional Technical Support

Have questions about our paper bags or customization services? We’re here to assist you every step of the way. Whether you need expert advice from past projects or hands-on support tailored to your packaging requirements, our dedicated team is ready to provide prompt and reliable assistance. We are committed to making your experience seamless and delivering the best solutions to help your business succeed.

JiaRong Packaging has been committed to delivering high-quality, customizable, and eco-friendly paper bag solutions for years. We offer a wide variety of paper bags, including kraft paper bags, coated paper bags, specialty paper bags, and more, ensuring each product meets your unique requirements. Choose JiaRong Packaging for superior quality and dependable service that supports your business growth.

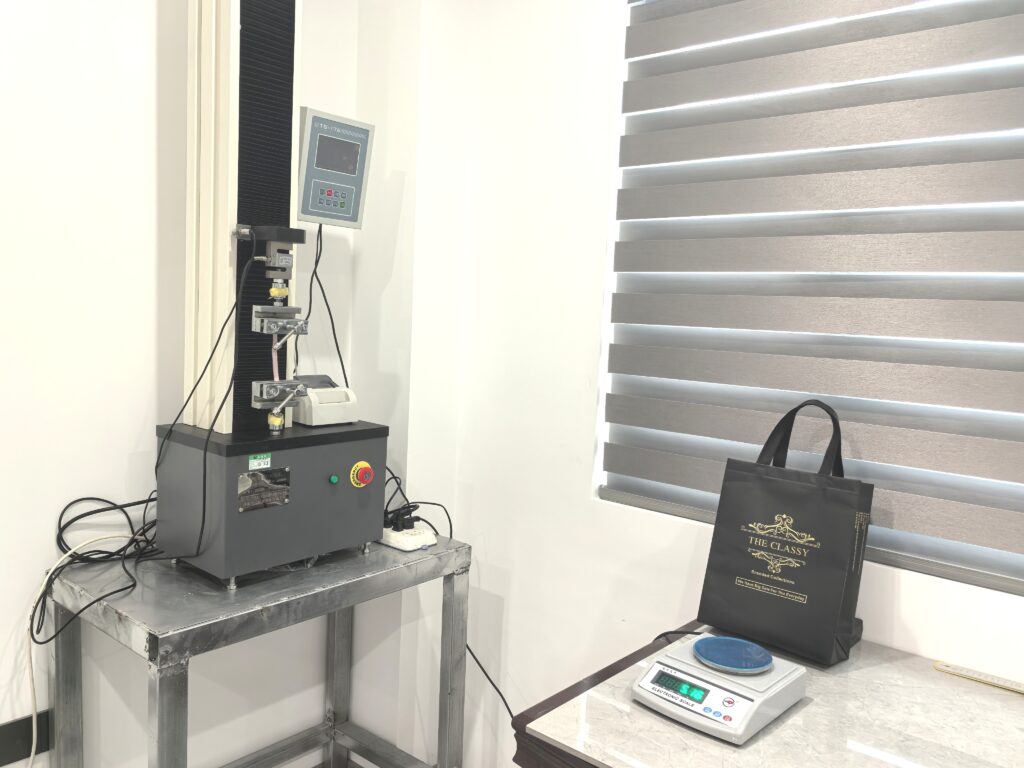

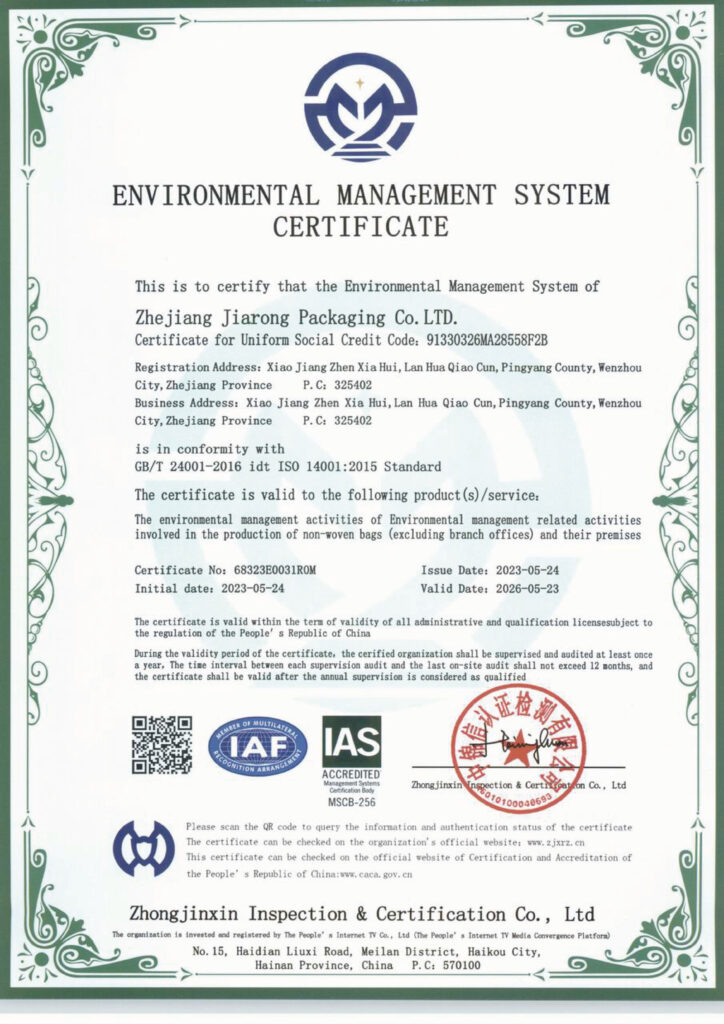

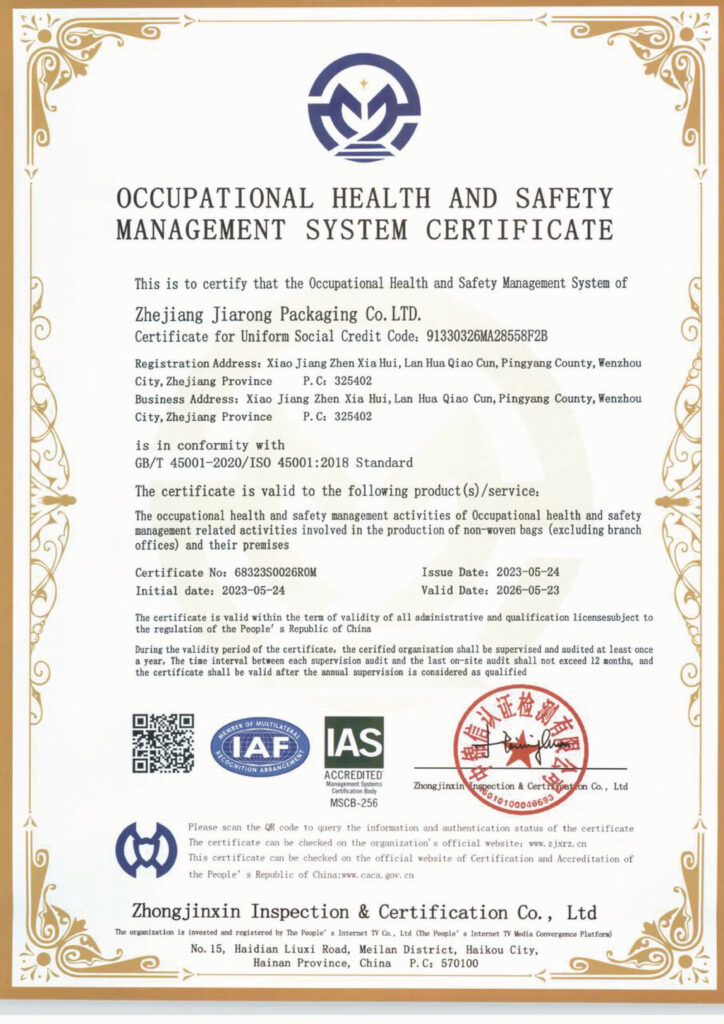

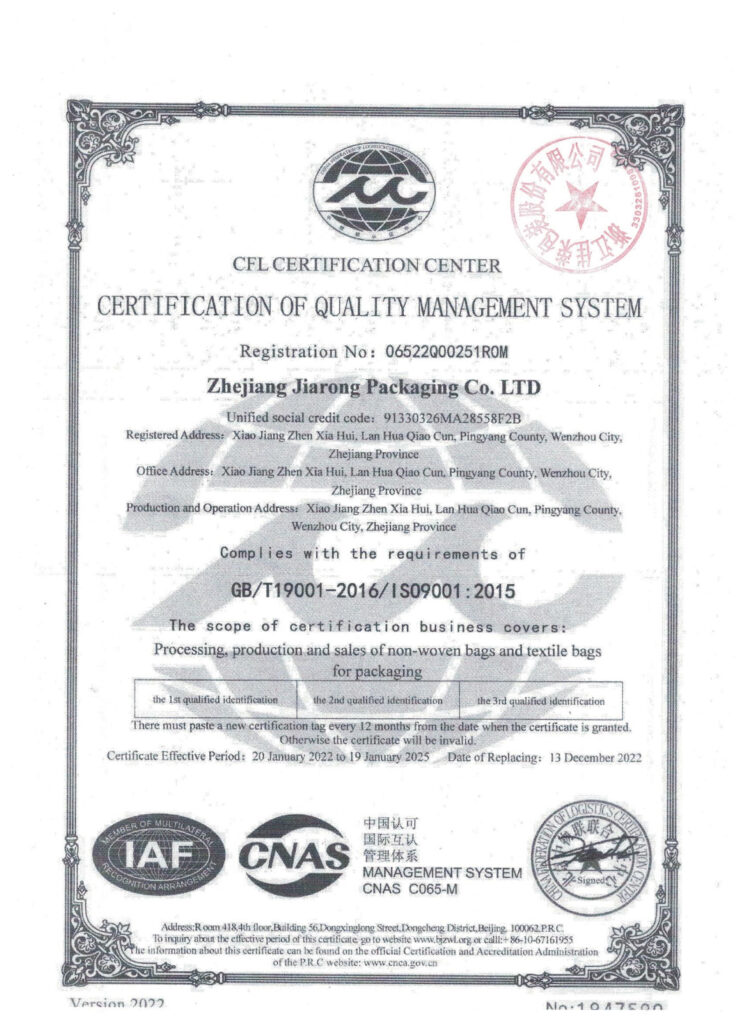

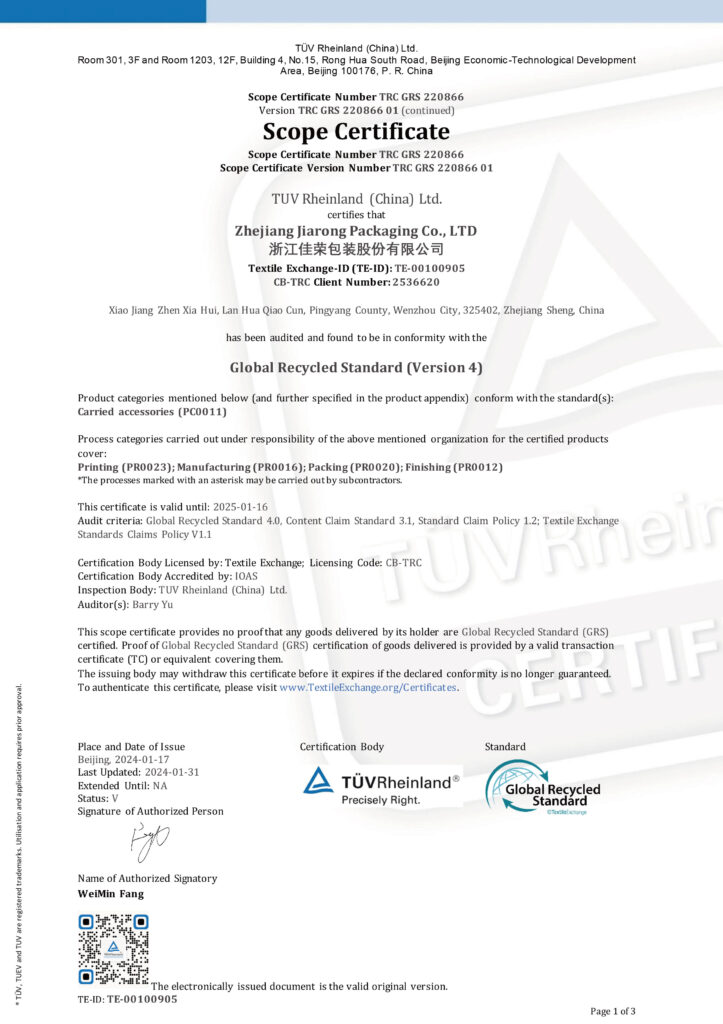

Worried about product quality? JiaRong Packaging is ISO 9001:2015 certified, ensuring every product meets international standards for consistent and reliable quality.

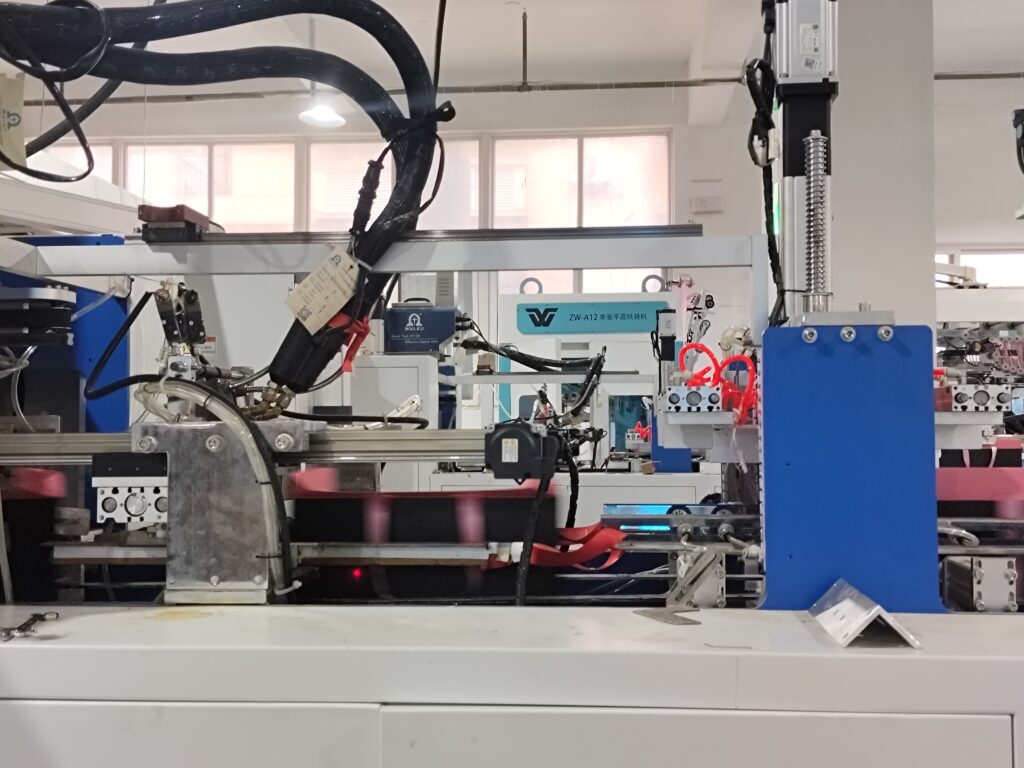

Concerned about production limits? With over 16,000 square meters of factory space and advanced equipment, we can handle orders of any size, from small batches to large-scale production.

Need versatile packaging solutions? We provide a broad selection of paper bags, including kraft paper bags, coated paper bags, specialty paper bags, and more. Our products serve supermarkets, hotels, restaurants, and a variety of other industries, delivering durable and eco-friendly packaging tailored to your needs.

Unsure about quality? We enforce stringent quality control at every stage, from raw material sourcing to final production, ensuring every product meets the highest standards.

Looking for a reliable partner? JiaRong Packaging has earned multiple honors, including the “Industrial Science and Technology Innovation Award” and “AAA Credit Enterprise,” reflecting our strength and credibility.

Planning to expand globally? Our products are exported to Europe, the U.S., Asia, and other regions, giving you the confidence of working with a partner equipped for international markets

Paper bags are essential across a wide range of industries, from retail to food service, offering businesses a sustainable, reliable, and high-quality packaging solution. Whether you’re looking to source bulk paper bags for your products or build a local wholesale distribution network, this guide provides key insights to help you make informed and confident decisions.

A waistline-free paper bag is a type of paper bag designed without the traditional horizontal seam (waistline) around the body. This seamless construction offers a cleaner appearance and improved strength, making it an ideal packaging solution for both aesthetics and functionality.

Waistline-free paper bags are widely appreciated for their simplicity, durability, and eco-friendliness. They can be fully customized in size, color, paper type, and printing — including logos and QR codes — to suit a wide range of business needs, from retail and food service to promotional and gift packaging. Their recyclable nature and clean structure make them a preferred choice for brands committed to sustainable and professional packaging.

We offer a carefully selected range of paper materials to meet diverse packaging needs. Each paper type offers distinct advantages in strength, texture, print quality, and environmental performance.

Durable, tear-resistant, and naturally eco-friendly

Ideal for everyday packaging and brands focused on sustainability

Available in brown and white, with a natural texture and strong load capacity

Smooth surface with excellent print clarity and vibrant color output

Ideal for retail, promotional, and luxury shopping bags

Supports high-resolution graphics, lamination, and special finishes

Rigid and thick with a high stiffness rating

Excellent for premium gift bags and branded corporate packaging

Supports embossing, foil stamping, and other decorative finishes

Available in a variety of textures: embossed, pearlescent, recycled, and more

Enhances visual impact and tactile experience for high-end applications

Perfect for unique, customized, or seasonal packaging projects

Made from calcium carbonate, without wood pulp

Water-resistant, tear-resistant, and smooth to the touch

Suitable for moisture-sensitive packaging or eco-conscious premium designs

Usage-Based Guidance:

For lightweight paper bags, such as small retail or takeaway bags, a thickness of around 100–130 gsm kraft paper is typical.

For standard shopping bags used in supermarkets or boutiques, 140–180 gsm offers a good balance of durability and cost.

For heavy-duty or premium gift bags, thicker paper of 200 gsm or above is recommended to ensure strength and an upscale feel.

Cost Considerations:

Thicker paper materials increase production costs, so it’s important to select a gsm that aligns with your budget and the bag’s intended purpose.

Printing and Branding:

For vibrant and detailed printing, using paper with at least 140 gsm provides a smoother surface and better ink adhesion, resulting in clearer logos and designs.

Choose high-quality paper materials (e.g., kraft paper, coated paper, specialty paper) based on required thickness, strength, and print compatibility. Inspect raw paper rolls or sheets for defects and ensure consistent quality.

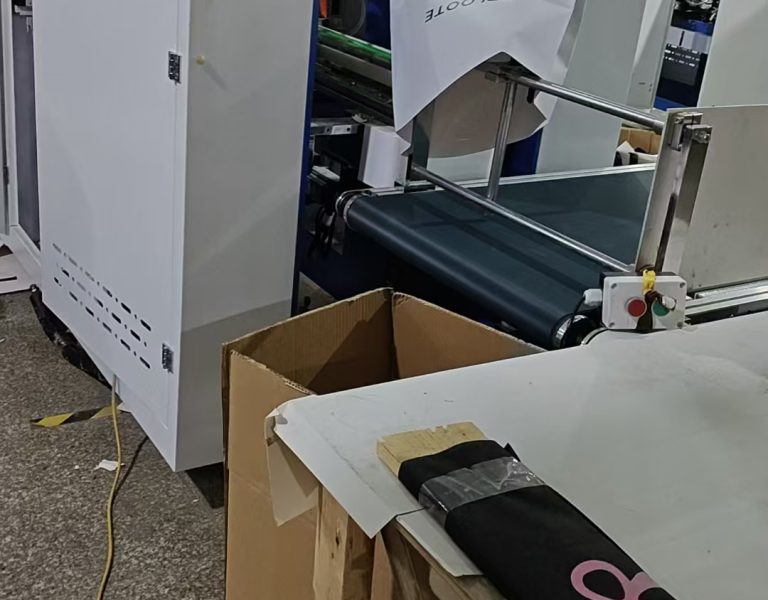

Apply customized printing designs, logos, and QR codes on the paper using suitable printing techniques (e.g., flexographic, offset, or digital printing). Follow with proper drying or curing to fix the ink and maintain print clarity.

Cut printed paper into precise flat blanks according to bag size specifications. Pre-fold edges and crease lines to prepare for seamless assembly, ensuring accurate alignment without the traditional waistline seam.

Material Cutting:

High-quality paper sheets are precisely cut into flat blanks according to the bag’s size specifications, including the main body, bottom, and handle components.

Assembly:

The cut pieces are folded and bonded using hot-melt adhesive pressure sealing, forming a seamless bag structure without a waistline seam. Additional reinforcements may be applied to the bottom and handle areas to enhance durability and load capacity.

The finished paper bags undergo a rigorous quality control inspection. Quality inspectors examine each bag for defects such as uneven gluing, printing inaccuracies, dimensional consistency, and overall structural integrity. Only bags that fully comply with our strict quality standards are approved for packaging and shipment.

After passing quality inspection, the paper bags are carefully folded and packed. They are typically bundled and placed into cartons or custom packaging, ready for shipment and export.

At JiaRong Packaging, our state-of-the-art machinery and skilled team guarantee efficient production of high-quality paper bags, providing customized solutions precisely tailored to meet our customers’ unique requirements.

Paper bags are typically printed using flexographic printing, offset lithography, digital printing, and screen printing. Each technique suits different design complexities, order sizes, and budget considerations:

These additional finishing processes greatly enhance the functionality and visual appeal of paper bags, adapting them to a variety of usage scenarios. Businesses can choose the most suitable techniques based on their branding goals and bag applications. JiaRong Packaging provides a comprehensive range of customization services to help your paper bags stand out in the market!

Applying a thin protective film on the paper surface enhances durability, water resistance, and overall appearance. Matte lamination offers a sophisticated, non-reflective finish, while glossy lamination adds shine and vibrancy.

This process uses heat and pressure to apply metallic or colored foil accents onto the bag, creating luxurious and eye-catching details. It’s ideal for premium branding elements like logos and decorative patterns.

Embossing raises a design or logo above the paper surface, while debossing presses it inward. Both techniques add tactile depth and elegance to your packaging, increasing brand recognition through touch and visual interest.

A selective glossy coating applied to specific areas of the bag, such as logos or patterns, to create contrast and highlight key design features. It enhances the visual appeal and provides a unique textured effect.

Here are some common styles and sizes for your reference

Natural Brown Kraft

White Kraft / White Cardboard

Black

Navy Blue

Red / Burgundy

Custom Pantone® Colors available upon request

(White / Black / Burgundy230g)28*20*10

(White / Black / Burgundy230g)31*25*11

(White / Black / Burgundy230g)35*26*13

(White / Black / Burgundy230g)38*28*13

(White / Black / Burgundy250g)43*32*13

(White / Black / Burgundy250g)50*35*14

Paper bags offer a clear advantage when it comes to print quality. Thanks to their smooth and uniform surface, especially with coated paper or white cardboard, they support vivid, high-resolution, and detailed printing. This makes them ideal for brands that prioritize strong visual identity and professional presentation. Techniques like offset printing, hot stamping, embossing, and spot UV are more precise and visually striking on paper than on non-woven fabric.

In contrast, non-woven bags have a textured, porous surface that limits printing sharpness and color vibrancy. While suitable for basic branding, their print results are generally less refined and may appear dull compared to paper.

However, each material has its own strengths:

Paper Bags

✅ Superior print clarity and finish

✅ Recyclable and biodegradable

❌ Less water-resistant without lamination

❌ Can be more prone to tearing under excessive weight

Non-Woven Bags

✅ More durable and reusable for long-term use

✅ Better resistance to moisture and physical wear

❌ Limited print detail and color saturation

❌ Less premium look and feel for high-end branding

If your priority is premium branding, rich color output, and fine design detailing, paper bags are the better option. For durability, reusability, and moisture resistance, non-woven bags remain a strong choice. JiaRong Packaging offers both options with full customization to match your exact business needs.

=The cost of paper bags can vary based on multiple factors. Understanding these key elements allows buyers to make informed choices, manage expectations, and optimize their packaging budgets effectively.

Material

GSM (Grams per Square Meter):

Higher GSM indicates thicker and more durable paper, which is ideal for heavy-duty use but increases material cost. Common ranges for paper bags are 100–250 gsm depending on the type and usage.

Type of Paper:

Kraft paper, coated paper, white cardboard, and specialty papers vary in cost. Additional treatments such as lamination (matte or glossy) or recycled content may also raise the price.

Size and Structure

Bag Dimensions:

Larger bags require more raw material and may involve additional structural reinforcement, impacting the overall cost.

Bag Design:

Custom structural elements—such as reinforced bottoms, twisted rope or ribbon handles, and special closures—can increase labor and material costs.

Printing and Finishing

Printing Method:

Offset Printing offers high-quality color reproduction and is economical for medium to large runs.

Digital Printing is suitable for small batches and personalized designs but has a higher unit cost.

Screen Printing is used for simple designs and solid colors with low setup costs.

Finishing Techniques:

Processes like hot stamping, embossing, spot UV, and lamination add visual appeal but also contribute to higher production costs.

Paper bags are widely used across various industries for their eco-friendliness, printability, and sustainable appeal. However, both businesses and consumers may encounter certain challenges during their production, handling, or use. Below is a detailed overview of common issues and practical solutions to ensure optimal performance and customer satisfaction.

Issue:

Paper bags can tear or collapse under heavy weight if made from low GSM paper or without reinforced bottoms and handles. Handles may also loosen or detach if not properly fixed.

Solution:

Use sturdy paper with higher GSM (typically 140 gsm or more) to enhance strength. Reinforce the bottom panel and securely attach handles—commonly twisted paper cords or flat ribbon handles—with double gluing and stitching. For extra durability, laminated paper or reinforced inserts can be added to support heavier loads and extend bag lifespan.

Issue:

Standard paper bags, if not made from recycled or sustainably sourced materials, may raise environmental concerns. Without proper treatment, paper bags can absorb moisture easily, reducing their lifespan and usability. Additionally, some consumers may be unsure about how eco-friendly these bags really are.

Solution:

Use recycled or FSC-certified paper to ensure sustainability and reduce environmental impact. Enhance moisture resistance with eco-friendly coatings or lamination while maintaining recyclability. Provide clear information on labels or marketing materials to educate consumers about the bag’s eco-friendly features and encourage reuse and proper recycling.

Issue:

Repeated use, exposure to moisture, or rough handling can weaken paper bags and cause tearing. Additionally, designs and colors may fade or smudge over time, diminishing the bag’s visual appeal.

Solution:

Apply a protective lamination layer—matte or glossy—to enhance moisture resistance and extend the bag’s lifespan while improving its look. Use high-quality inks and advanced printing methods, such as offset or gravure printing, to ensure vibrant, long-lasting colors. Educate customers on proper care, including avoiding excessive moisture and storing bags in dry environments to maintain durability and print quality.

Issue:

Producing complex, detailed, or multi-color designs on paper bags can be costly and technically demanding. Inadequate printing methods may cause fading, or inconsistent colors, impacting the bag’s appearance and brand image.

Solution:

Choose the printing technique that best fits your design complexity and budget:

Screen Printing: Suitable for simple, single-color logos or patterns.

Offset Printing: Ideal for high-quality, detailed, multi-color prints, especially for medium to large orders.

Digital Printing: Best for short runs and customized designs with fine details.

Collaborate with experienced suppliers to optimize artwork placement and reduce setup costs. Use high-quality, eco-friendly inks that offer durability and resist fading to maintain vibrant, long-lasting prints.

Paper bags are prone to creasing and bending, especially when stacked improperly or stored for long periods. Due to their delicate structure, they require careful handling and storage in dry, flat conditions to maintain shape and appearance.

To ensure the best quality, it’s recommended to ship paper bags promptly after production. Using flat packing with sturdy cardboard supports and moisture-resistant wrapping can minimize damage during transit and storage.

Efficient logistics coordination helps prevent excessive stacking and pressure, preserving the bags’ integrity until they reach the end customer.

Issue:

Enhanced features such as lamination, reinforced handles, or premium printing techniques increase production costs. Small batch orders typically have higher per-unit prices due to setup and tooling fees.

Solution:

Opt for bulk production to benefit from economies of scale and lower unit costs. Prioritize features based on actual needs—for example, choose lamination only when moisture resistance is essential. Partner with manufacturers who offer competitive pricing and flexible customization to balance quality and budget effectively.

.

By proactively addressing these potential challenges, businesses can improve the durability, appearance, and sustainability of their paper bags. At JiaRong Packaging, we emphasize quality and innovation to ensure our products meet the highest industry standards. Contact us today for customized packaging solutions tailored to your unique requirements!

Different types of shopping bags offer varying benefits and limitations. Here’s a comparison of some commonly used shopping bags to help businesses and consumers make informed choices:

| Bag Type | Durability | Eco-Friendliness | Cost | Customization | Ideal Use |

|---|---|---|---|---|---|

| Plastic Bags | Low | Poor | Very Low | Limited | Supermarkets, groceries |

| PP Woven Bags | High | Recyclable | Low-Medium | Excellent | Bulk shopping, promotions |

| Non-Woven Bags | Moderate | Recyclable | Low | Very Good | Retail, exhibitions |

| Canvas Bags | Very High | Biodegradable & reusable | High | Premium | Eco-conscious, high-end branding |

| Paper Bags | Low | Biodegradable & compostable | Low | Good | Lightweight items, eco branding |

Material: Polyethylene (PE)

Features:

Material: Woven polypropylene fabric

Features:

Material: Non-woven polypropylene fabric

Features:

Material: Cotton or canvas fabric

Features:

Material: Kraft paper or coated paper

Features:

Purchasing paper bags requires thoughtful planning to ensure quality, durability, and brand appeal—not just low cost.

Unlike traditional paper bags with waistline seams, seamless designs offer a cleaner look and stronger structure, reducing the risk of tearing under heavy loads. When sourcing, pay attention to material strength, appearance, and functionality to get the best value for your business.

Here’s a quick guide to help streamline the procurement process.

Supplier Credentials:

Choose experienced paper bag manufacturers with a proven track record in quality production and reliable service.

Certifications:

Ensure the supplier meets relevant environmental and quality standards, such as FSC certification, ISO 9001, or SGS testing.

Sample Inspection:

Request pre-production samples to evaluate material strength, print quality, and overall finish before placing a bulk order.

Specification Clarity:

Provide clear and detailed requirements to suppliers, including bag dimensions, paper type and GSM, handle style, printing details, and packaging method.

Quotation Comparison:

Collect quotes from multiple suppliers and compare not only pricing, but also production lead times, customization flexibility, and after-sales support.

By following these steps, businesses can ensure a smooth procurement process and secure high-quality paper bags—especially seamless (no-waistline) models—at competitive prices. At JiaRong Packaging, we provide expert manufacturing, strict quality control, and customizable solutions to meet your brand’s packaging needs. Contact us today to start your paper bag sourcing journey with confidence!

Printing plays a key role in cooler bag customization1. Companies use different methods depending on design complexity2, fabric type, cost, and durability3. Understanding the main

Cooler bags are popular for shopping, outdoor activities1, and food delivery2, but many buyers misunderstand the materials used in their construction. This article clears up

Cooler bags are essential in daily life, from picnics and camping to supermarket shopping and food delivery. Selling them globally requires smart distribution strategies that

The European cooler bag market1 in 2025 shows strong demand for stylish, multifunctional, and durable designs. In this article, we explore six popular cooler bag

Cooler bags are no longer just picnic accessories. They have become daily essentials for professionals, families, and outdoor enthusiasts. In this article, we explore seven

Understanding lead times1 for custom bulk orders is key to planning ahead. This article explains standard production2 timelines, fast options, and factors that affect delivery

Contact us for a free quote and more expertise on custom tote bags. Together with Jiarong Packaging, we will find the right solution for your project.

At Jiarong Packaging, we make it simple! Follow these 3 steps to get started today!

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

We will start mass production after getting your approval and deposit, and we will handle the shipment.

Jiarong Packaging - Non-woven and Insulated Bag Manufacturer

Typically replies within minutes

Any questions related to Paper bags?

WhatsApp Us

🟢 Online | Privacy policy

WhatsApp us

We’ll reach out to you within 8 hours. Please keep an eye out for an email from us, coming from the address ending in “@zjjrpackaging.com”

Don’t go away, there are free samples available here. Please leave your email address so I don’t miss you. We’ll reach out to you within 12 hours. Please keep an eye out for an email from us, coming from the Jiarong Packing.