Custom PP woven bags have become a preferred packaging solution across industries due to their superior functionality, durability, and branding capabilities. This article highlights the eight essential features that define high-quality, custom PP woven bags and explains why these features matter in real-world applications.

8 Must-Have Features in Custom PP Woven Bags

PP woven bags combine strength, versatility, and eco-friendliness, making them ideal for industries ranging from agriculture to retail.

Explore how each of these eight features contributes to the effectiveness of PP woven bags in demanding environments.

Exceptional Strength and Durability1

PP woven bags are engineered to withstand significant stress and weight without tearing. Their tensile strength allows for carrying loads from 20 kg to 50 kg or more, depending on the bag’s construction.

Why Strength Matters

The strength of these bags is a result of polypropylene fibers being woven into a durable fabric. This makes them ideal for industrial uses such as packaging cement, fertilizers, or grains, where handling heavy and sharp-edged contents is routine.

Applications and Benefits2

| Industry | Typical Load | Use Case Example |

|---|---|---|

| Construction | 40–50 kg | Cement and sand transport |

| Agriculture | 20–30 kg | Grains, seeds, fertilizers |

| Manufacturing | 30–40 kg | Hardware, bulk components |

Strong PP woven bags reduce the risk of spillage, protect goods during long-distance transit, and withstand mechanical loading processes without failure.

Lightweight Yet Robust

Despite their heavy-duty performance, PP woven bags remain lightweight. This feature significantly cuts down shipping costs and simplifies manual handling.

Weigh Less, Carry More

A typical 25 kg PP woven bag weighs only about 100–130 grams. This weight advantage reduces fuel costs and eases logistics without compromising the strength or integrity of the packaging.

Cost Comparison Table

| Packaging Material | Weight (empty) | Relative Shipping Cost |

|---|---|---|

| PP Woven Bag | 120g | Low |

| Paper Bag | 400g | High |

| Jute Bag | 600g | Higher |

For logistics-intensive industries, this feature directly translates into operational efficiency.

Moisture and Weather Resistance

Laminated PP woven bags provide a reliable barrier against moisture and adverse weather. This is critical for maintaining the integrity of contents sensitive to damp environments.

Lamination for Protection3

The bags are coated with polyethylene (PE) to repel water and humidity. This is especially important in regions with high rainfall or products that must remain dry, like rice or animal feed.

Moisture Resistance Impact

| Lamination Type | Water Resistance | Ideal Use |

|---|---|---|

| None | Low | Breathable goods like potatoes |

| Light Laminate | Medium | Dry food items |

| Full Laminate | High | Chemicals, grains, powdered goods |

This feature ensures product quality from factory to shelf, even during seasonal weather shifts.

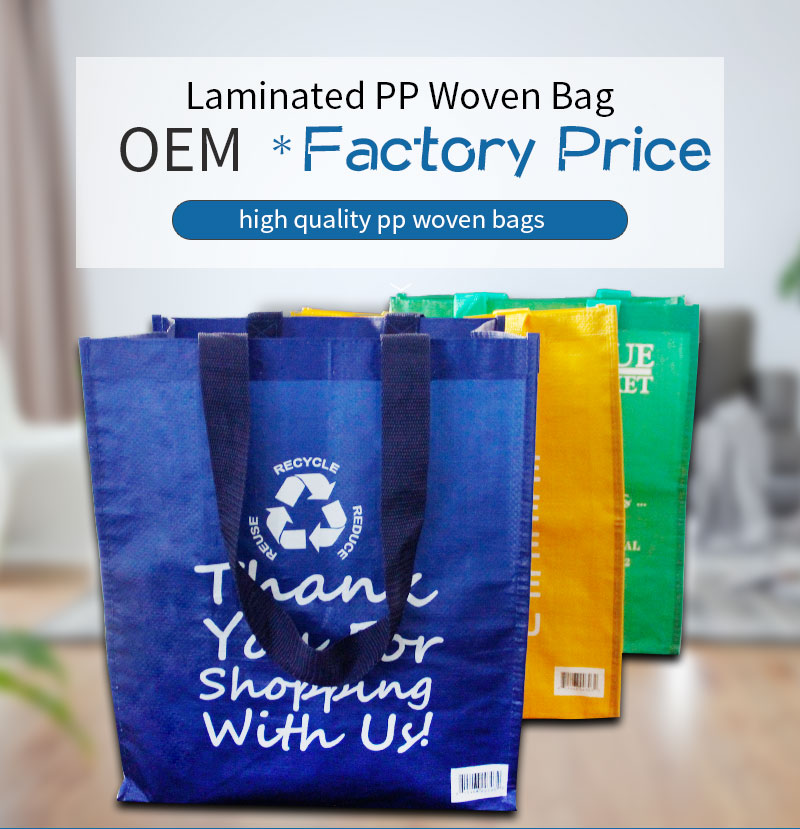

Customizable Printing and Branding

PP woven bags offer ample surface area for customized printing. Businesses can add logos, promotional designs, or product info, turning every bag into a branding asset.

Boosting Brand Visibility

With rotogravure or flexographic printing on laminated surfaces, vibrant and durable graphics can be produced. This transforms the bag from simple packaging into mobile advertising.

Branding Potential

| Feature | Benefit |

|---|---|

| Full-color printing | High visual impact |

| Logo placement | Reinforces brand recognition |

| QR code or info print | Engages consumers post-purchase |

Customized PP woven bags are especially effective in retail environments and trade shows.

Versatile Design Options

PP woven bags can be tailored in terms of size, shape, closure type, and accessories. This flexibility helps meet industry-specific packaging needs.

Choose Your Style

Whether it’s a gusseted bag for bulky materials or a drawstring bag for promotional giveaways, PP woven bags can be customized in countless ways.

Customization Table

| Design Element | Options Available |

|---|---|

| Closure Type | Zipper, drawstring, Velcro |

| Bag Shape | Flat, gusseted, circular |

| Handle Type | Loop handle, die-cut, padded |

| Color/Print | CMYK, Pantone, single/multi-color |

This allows businesses to align packaging with product type and customer expectations.

Breathability (Optional)

Some PP woven bags are designed to be breathable. This option is valuable for perishable products that need air circulation, such as onions, potatoes, or coffee beans.

Airflow for Freshness

While lamination prevents moisture ingress, breathable variants have micro-perforations or non-laminated sections that allow air to circulate. This prevents mold and prolongs shelf life.

Breathability Comparison

| Bag Type | Breathable | Best for |

|---|---|---|

| Fully Laminated | No | Chemicals, powders |

| Non-Laminated | Yes | Vegetables, grains |

| Micro-Perforated | Partial | Coffee, seeds |

Choosing between breathability and moisture protection depends on the contents and the logistics timeline.

Enhanced Stability Features

PP woven bags can include reinforced bottoms, internal baffles, or box-shaped designs to improve stacking and prevent deformation during loading.

Better Shape Retention

Stability features reduce sagging and allow easier pallet stacking, helping logistics teams load more effectively and reduce shipping damage.

Stability Options

| Feature | Function |

|---|---|

| Reinforced Bottom | Prevents tearing at base |

| Internal Baffles | Maintains bag shape when full |

| Box Construction | Ideal for automated stacking |

These upgrades are essential for industrial settings and warehouse operations.

Eco-Friendly and Reusable

PP woven bags are recyclable and can be reused many times. This reduces environmental impact and supports sustainable supply chain goals.

Sustainability in Practice

Reusable packaging saves cost in the long term and lowers waste. When a bag can be used 20–50 times before recycling, it offers a greener alternative to single-use options.

Sustainability Benefits

| Feature | Environmental Impact |

|---|---|

| Reusability | Reduces demand for new raw materials |

| Recyclability | Fits into circular economy packaging models |

| Low Energy Use | Lower carbon footprint than paper or plastic |

Eco-conscious buyers often choose PP woven bags to meet regulatory standards and corporate ESG targets.

Conclusion

Custom PP woven bags offer a powerful combination of durability, flexibility, and sustainability. Their unique construction and customizable features make them ideal for industries ranging from agriculture to e-commerce. In our experience at JiaRong Packing, we've helped many clients boost both their packaging performance and brand image using high-quality, tailored PP woven bags.

If you're a business looking to improve packaging efficiency or showcase your brand better, custom PP woven bags are worth considering. Explore how our factory's production capabilities can help your business stand out.

We’d love to hear your thoughts or experiences with PP woven bags—leave a comment below!