PP Woven Shopping Bag Manufacturer

Factory-Direct | Best Prices!

No middlemen, just lower costs & higher profits! ✅ Durable ✅ Customizable ✅ Wholesale Only

Looking for cost-effective bulk PP woven shopping bags?

With an annual production of up to 700 million bags, we offer competitive prices driven by large-scale manufacturing, helping you reduce costs while ensuring stable quality.

Concerned about high minimum order quantities?

We offer a low MOQ of just 1000 pieces, giving you flexibility to meet your needs.

Worried about quality?

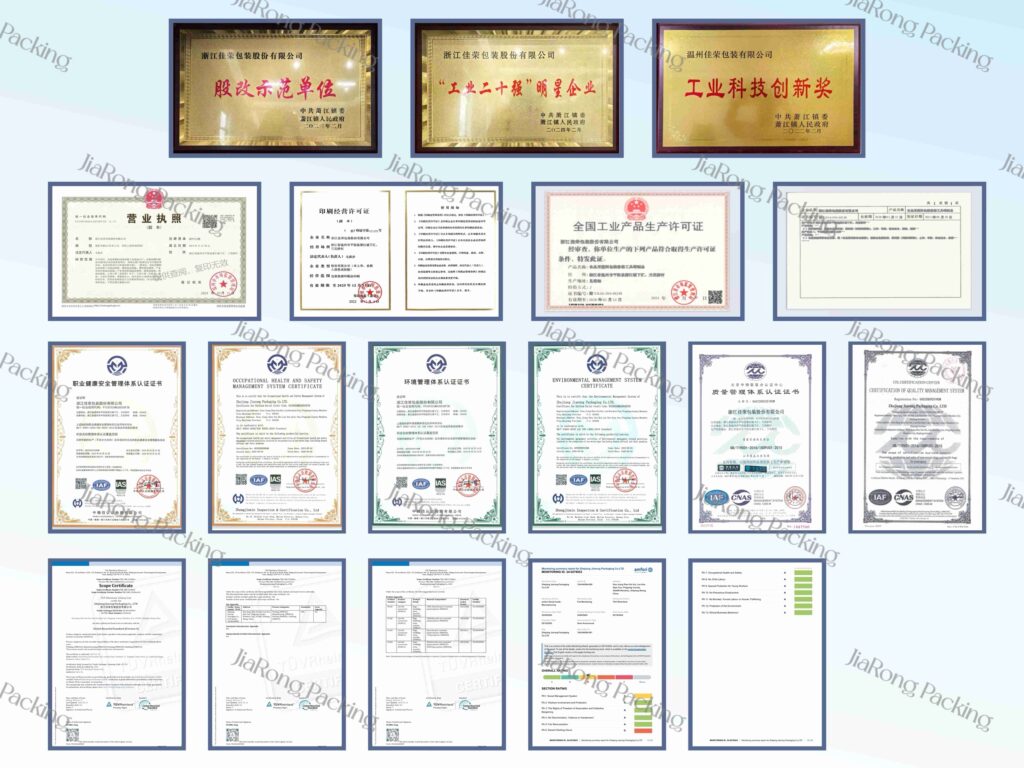

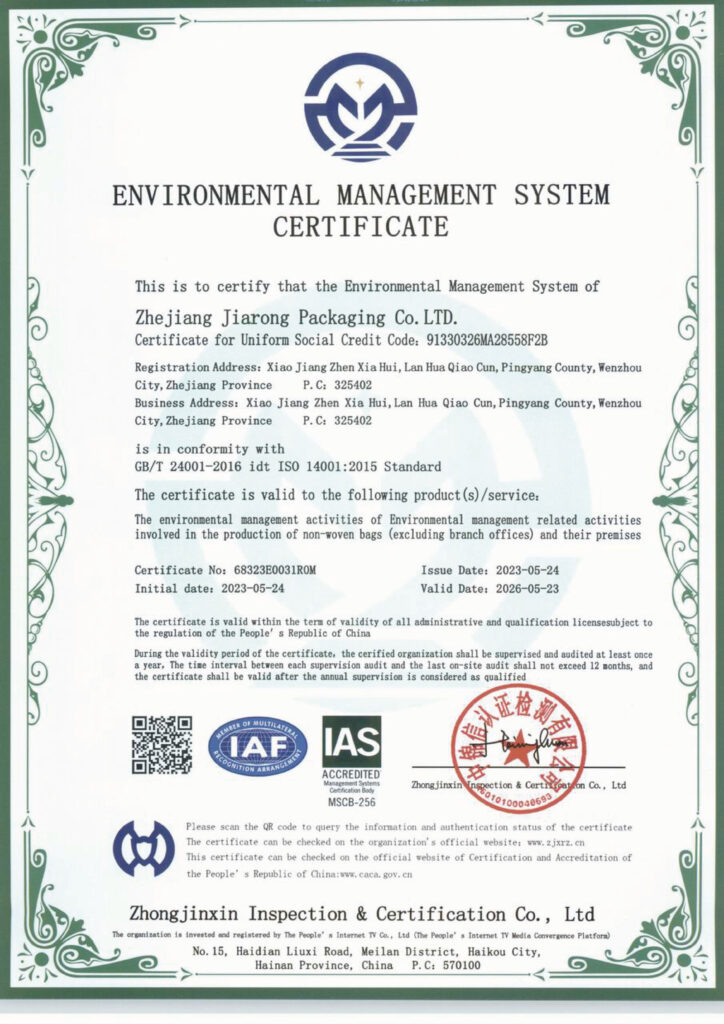

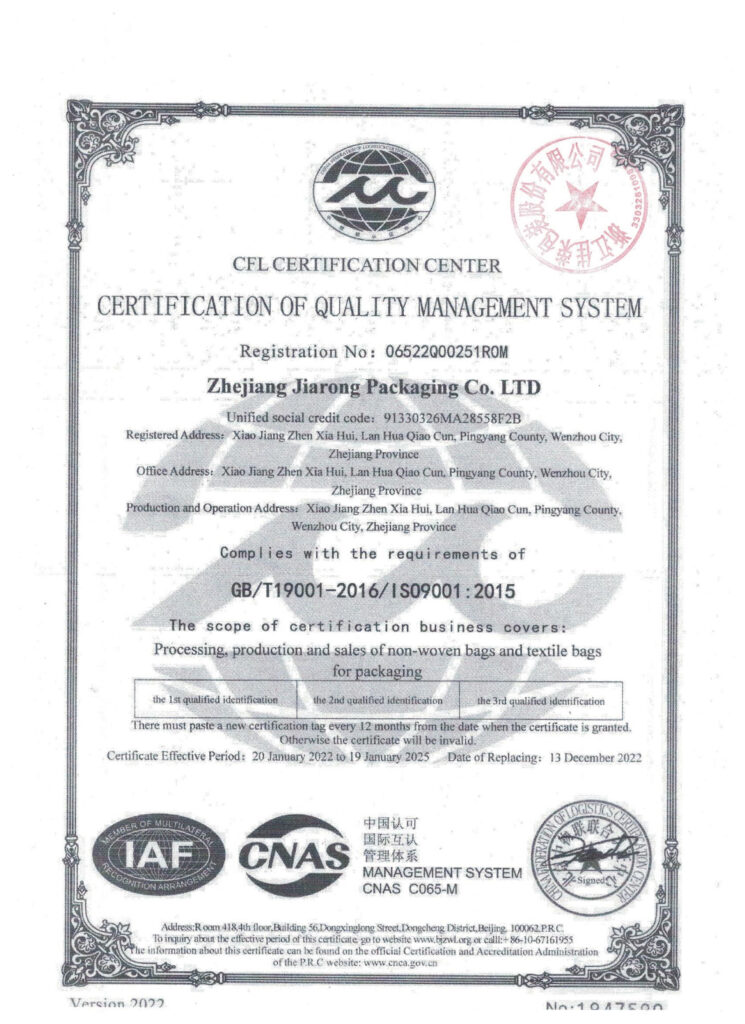

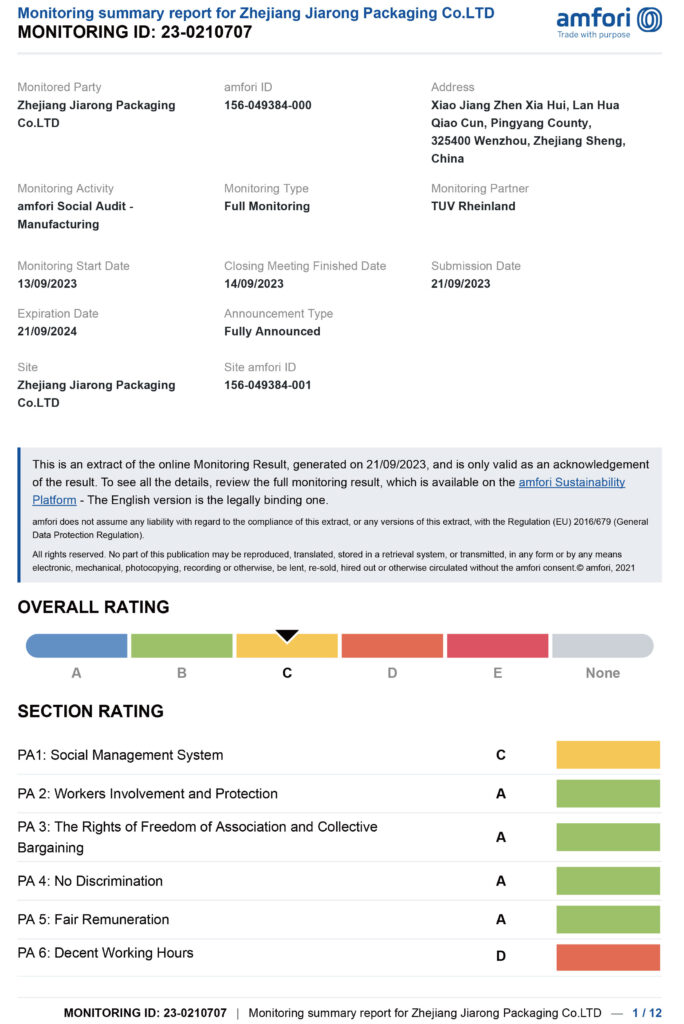

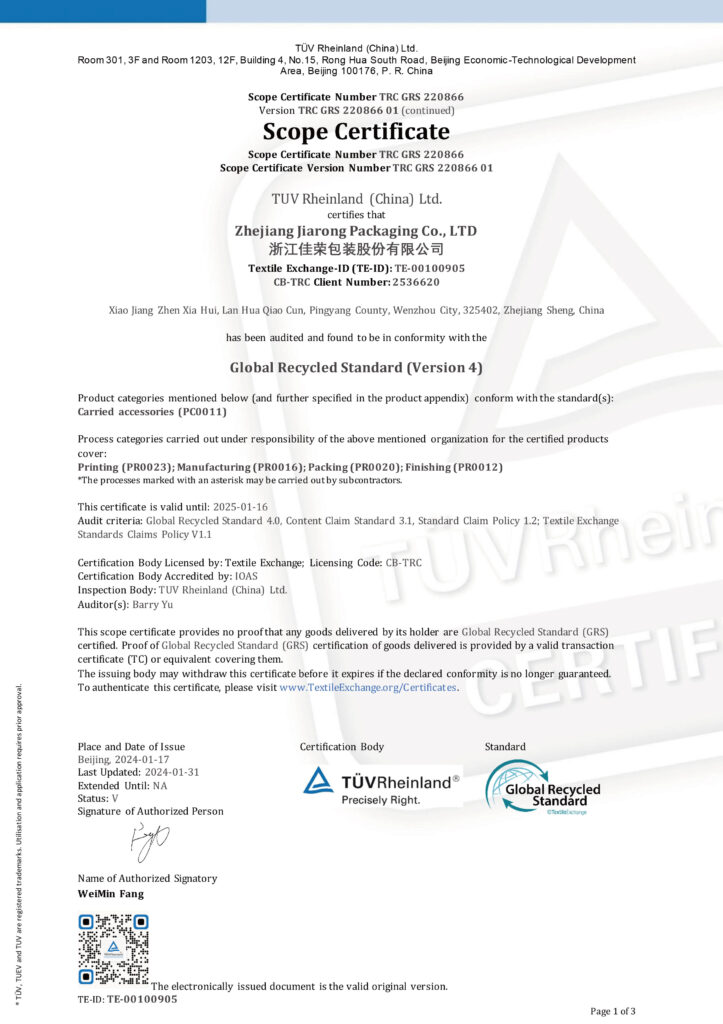

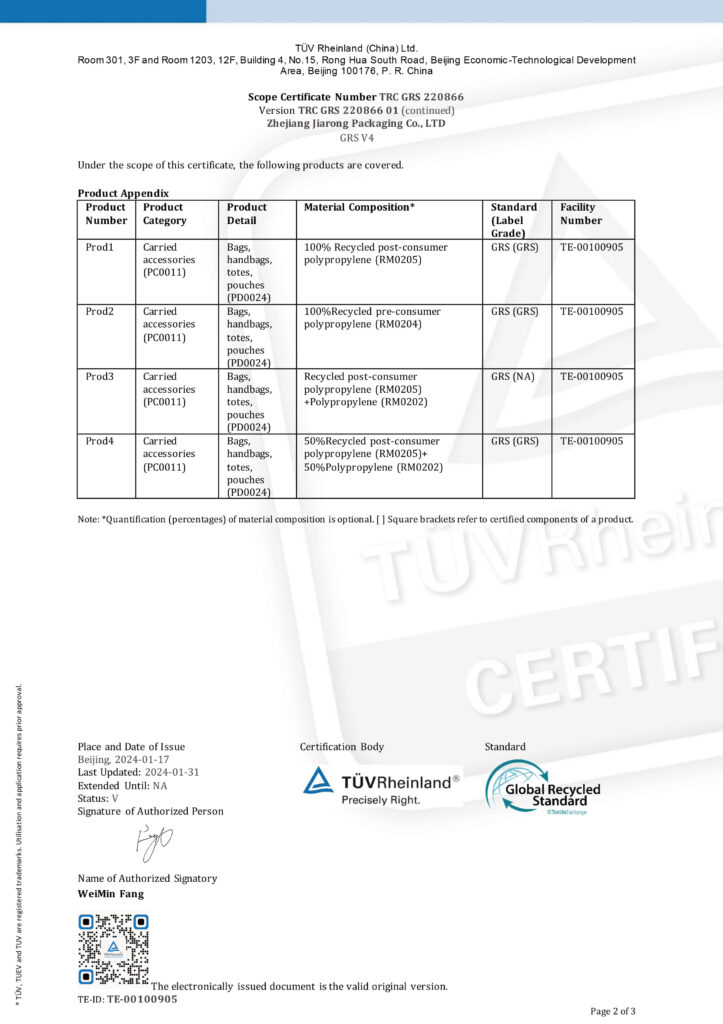

Our products are ISO9001 and ISO14001 certified, ensuring high quality and environmental responsibility through strict production standards.

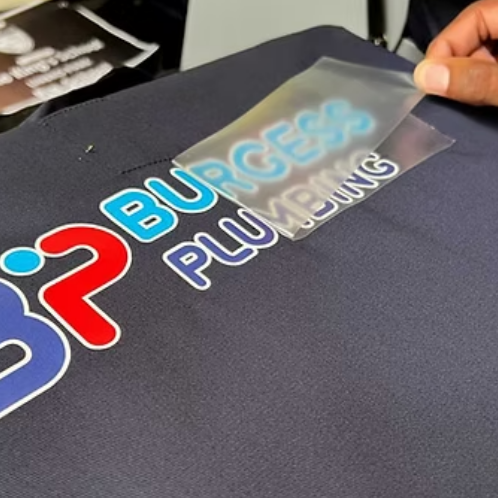

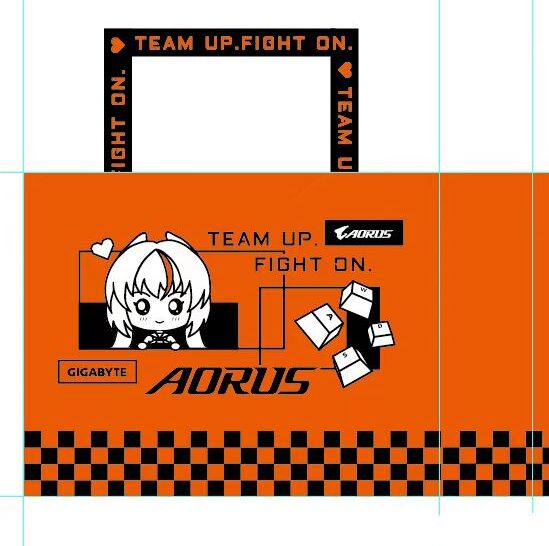

Transform Your Vision into Quality Handbags

At JiaRong Packaging, we specialize in turning your ideas into premium, eco-friendly handbags. With advanced manufacturing capabilities and a skilled team, we provide seamless support from concept to production. Whether you need custom designs, durable materials, or reliable delivery, we ensure your vision becomes a reality efficiently and affordably.

Our Customized Products

We offer a wide range of customizable PP woven shopping bags to meet your unique requirements. Whether you need specific sizes, colors, or logo printing, we work with you to create the perfect product for your business.

Durable, eco-friendly, and stylish, our PP woven boat-shaped shopping bags are perfect for heavy-duty use. These reusable bags feature a unique design, ample storage, and customizable branding options, making them ideal for supermarkets, retail stores, and promotions.

Durable, spacious, and eco-friendly, our PP woven gusseted shopping bags feature reinforced sides and bottoms for extra capacity. Perfect for supermarkets, retail packaging, and promotions, these reusable bags can be customized with your logo for effective branding.

Our moon-shaped PP woven shopping bags feature a unique curved design, offering a stylish yet functional solution for your packaging needs. These durable and eco-friendly bags are ideal for retail stores, promotional events, and everyday use.

Stylish and eco-friendly, this kraft-laminated PP woven shopping bag combines the natural look of kraft paper with the strength of PP woven material. It’s perfect for retail, gifting, or promotional purposes, offering durability and a professional design.

Our zippered PP woven tote bags offer a secure, durable, and eco-friendly solution for various packaging needs. With a sturdy structure and convenient zipper closure, these bags are ideal for retail, shopping, and promotional events.

Our PP woven sports bags combine durability, functionality, and style, making them ideal for fitness, travel, and outdoor activities. Lightweight yet strong, they are designed to withstand daily use while being eco-friendly and reusable.

This stylish printed transparent PP woven tote bag combines a trendy design with durability, making it perfect for shopping, promotions, and everyday use. Its lightweight and spacious construction ensures convenience while promoting your brand with customizable designs.

Our PP woven tote bags with double handles are designed for durability and convenience, making them the ideal choice for businesses seeking reliable and reusable packaging solutions. Crafted from premium polypropylene material, these bags offer excellent strength, are resistant to wear and tear, and can handle heavy loads with ease.

Our PP woven insulated bags are the perfect solution for businesses that need reliable and durable thermal storage options. These bags are crafted with premium polypropylene woven fabric and insulated layers, ensuring excellent temperature retention for hot or cold items. Designed for practicality and customization, they are ideal for a wide range of industries.

We're There Every Step of The Way

01

Custom Design

At JiaRong Packaging, we specialize in delivering customized packaging solutions tailored to your business needs. From PP woven shopping bags to takeaway and promotional bags, we offer a variety of options in design, size, color, and logo customization to perfectly match your brand identity.

05

Shipping

First, we work with top logistic, courier and Freight agent allowing us the most competitive transit time and pricing. Secondly, we provide packaging materials such as cartons, waterproof woven bags or pallets according to bag shape and order size.Want your material crated? We can do that too!

What Sets Us Apart

Strong Capacity

Looking for a reliable, large-scale production partner? Our 16,000 m² factory boasts a 350 million RMB annual output and a daily capacity of three million handbags. Let us boost your brand with consistent supply and superior craftsmanship.

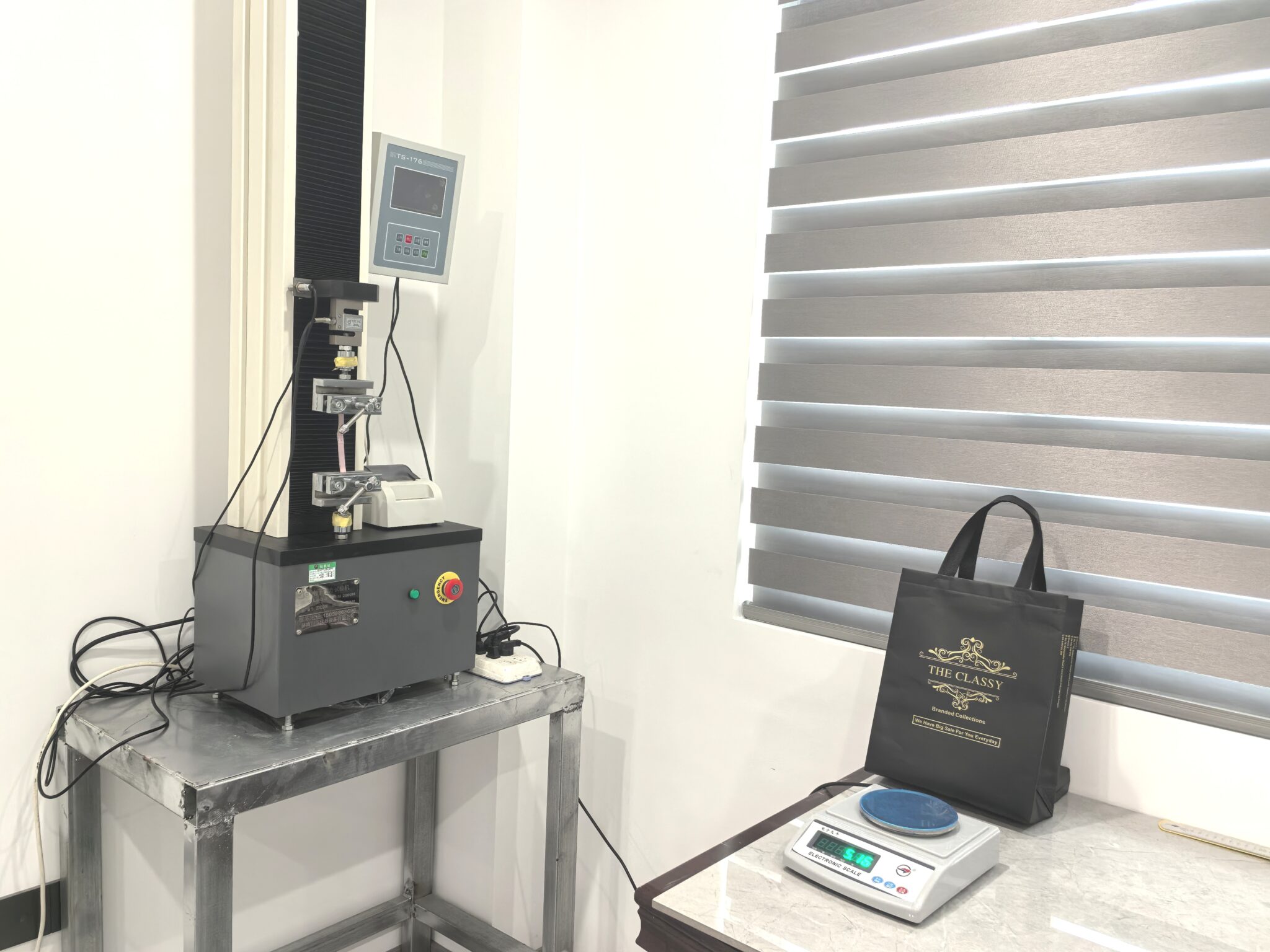

Well-equiped

We’ve introduced 43 one-time forming non-woven bag machines, 8 high-speed color printers, 6 double-head laminators, and 100 sewing machines for a fully automated, professional process.

Let us help your brand rise above the competition.

Favorable Price

Up to 10% lower raw material costs contributed by bulk order needs and stable supply guaranteed by manufacturing process, make it possible for our lower price.

Full Support & Service

From pre-sales to manufacture and after-sales, we will provide the tailored solution according to your design and quote within 24 hours

Production Short Video

Our Qualifications And Certificates

Our Quality Inspection

At JiaRong Packaging, quality is our top priority. Every bag undergoes a thorough inspection process, from raw materials to finished products. We perform rigorous tests to ensure durability, load capacity, and flawless craftsmanship.

Our commitment to strict quality standards guarantees that every bag not only meets but exceeds your expectations. With our reliable inspection system, you can trust us to deliver eco-friendly, durable, and high-quality non-woven bags for all your needs.

Start your Packaging Journey

Find the right packaging solution for your needs by exploring our selection of packaging solutions

Claim Your Free Sample Today!

How to Get Your Sample?

- Contact us with your details.

- Let us know your preferred bag type and specifications.

- We’ll ship your free sample right to your door!

Don’t miss out—request your free sample now and discover products that match your business needs!

Customized Shopping Bags

At Jiarong Packaging, we make it simple! Follow these 3 steps to get started today!

1.Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

2.Get Solution & Quote

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

3.Approve for Mass Production

We will start mass production after getting your approval and deposit, and we will handle the shipment.

Phone/WhatsApp:

86-138 6836 8539

86-152 6771 9222